The Fiber Carding Machine is an essential piece of industrial fiber recycling equipment widely used in textile production. Its primary role is to loosen and comb various fibers through opening, carding, and impurity-removal processes, preparing them for the next stages of manufacturing.

This machine is capable of handling a wide range of raw materials, including chemical fibers, linen spinning materials, cotton spinning materials, wool fibers, waste yarn, discarded garments, textile scraps, and non-woven fabrics.

Features of fiber carding machine

- Powerful opening and fine carding. Through the high-speed rotating stab rollers and rollers, it can effectively loosen the fiber clumps. And after many times of carding, fibers become softer and neater, suitable for subsequent processing.

- Efficiently removing impurities and dust. Adopting high-power suction fan, it can effectively remove the dust and fine impurities in the fiber to ensure the cleanliness of the fiber.

- High degree of automation. It is equipped with advanced control system, easy to operate, with one-key start, automatic shutdown and other functions.

- Versatility. It can handle many types of fiber raw materials, including chemical fiber, linen, cotton and so on.

- Easy maintenance. The machine is upgradable, so it is easy to replace the wearing parts such as blades and spiked rollers, which reduces the maintenance cost.

- Support customization. Customers can customize the number of rollers and the installation of the fence according to the demand. The more the number of rollers, the better the effect of processing materials.

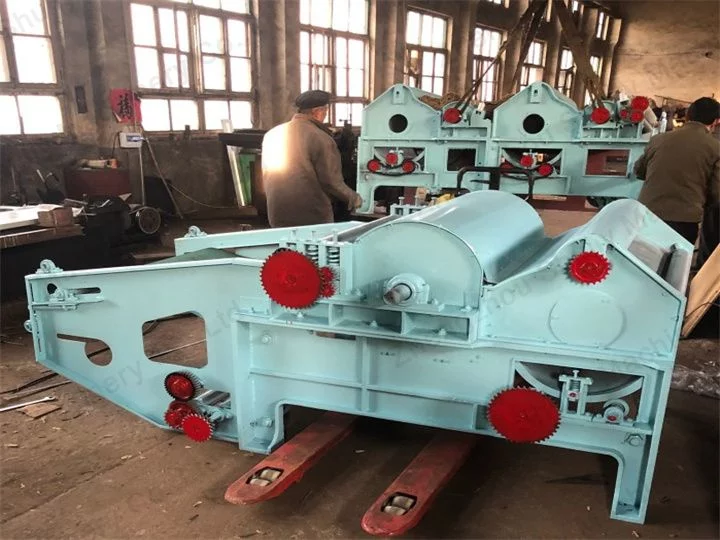

Textile carding machine structure

- Frame: the support structure of the fiber carding machine. Made of steel with good stability and durability.

- Feeding device: the fiber material to be treated is fed into the machine through the conveyor belt.

- Opening system: it is the heart of the machine. Inside there are several cleaning elements (e.g. cleaning needles, rollers, etc.), which are used to loosen the fibers further and comb the fibers to remove the impurities in them.

- Dedusting system: it is used to generate airflow to separate and collect the cleaned impurities and dust to ensure the purity of the fibers after cleaning.

- Control system: it is equipped with an electrical control cabinet to monitor and control the operation of the blow room. It is also equipped with safety protection devices to ensure the safe operation of the equipment.

How does a fiber carding machine work?

- Material Preparation: Raw materials such as waste garments and yarns are fed into the Fiber Carding Machine through the feed opening.

- Opening: The machine uses a conveyor belt and rotating rollers to unfold the materials, while a high-speed needle roller further loosens the fiber clumps.

- Carding: Loosened fibers pass through a dust cage and debris removal plate to separate impurities.

- Cleaning: A suction fan or dust removal system extracts dust and fine particles from the fibers.

- Output: The cleaned fibers are compressed by the dust cage and calender rollers and discharged for collection.

Fiber carding machine parameters

| Model | Capacity(kg) | Power(kw) | Size (mm) | Roller length(mm) | Roller dia(mm) | Weight(kg) |

| SL250B | 150-250 | 11 | 2000X1700X1300 | 1000 | 250 | 800 |

| SL250B-2 Roller | 150-250 | 29 | 2900X1700X1300 | 1000 | 250 | 1500 |

| SL250C-3 Roller | 150-250 | 34 | 4000X1700X1300 | 1000 | 250 | 2350 |

| SL250D-4 Roller | 150-250 | 40 | 5100X1700X1300 | 1000 | 250 | 3200 |

| SL250E-5 Roller | 150-250 | 45.5 | 6200X1700X1300 | 1000 | 250 | 4050 |

As you can see from the parameter table, we have many different types and outputs of roller carding machine for sale. If you are interested in a particular machine, you can contact us.

Cotton carding machine price

Basic, smaller capacity cotton carding machines designed for small-scale operations may cost a few thousand dollars. Larger, more advanced models used in industrial settings can cost tens of thousands of dollars or more.

To get an accurate and up-to-date price for a cotton carding machine, I recommend contacting professional roller carding machine manufacturers directly. We can provide you with current pricing information and details about specific models that meet your requirements. Additionally, you can compare prices from multiple sources to find the best deal for the machine that suits your needs.

Reliable fiber carding machine manufacturer

- A wide range of fiber recovery equipment is available. Shuliy Recycling Machinery is a reliable manufacturer specializing in the research and development of textile recycling machinery. We offer a wide range of textile recycling machines, including fiber opening machines, fiber cutting machines, textile balers, and so on.

- Increasing number of global cooperative customers. As a professional and experienced cotton carding machine manufacturer, our machines have been exported to more than 30 countries and regions around the world.

- Customized services. We also provide unique customized services for different customers’ needs. If you are looking for high-quality machines, please feel free to contact us, and we will contact you as soon as possible.

Fiber carding machine applications

Fiber carding machines find extensive applications in the textile industry, where they are employed to process various raw fibers, such as cotton, wool, and synthetics, ensuring uniformity and alignment before spinning into yarn.

Additionally, these textile recycling machines are vital in non-textile industrial settings for recycling applications. In the mattress and bedding industry, wool carding machines are used to create cushioning materials. Furthermore, they play a key role in automotive manufacturing, providing insulation and soundproofing materials.

In summary, drum carding machine is versatile. It can be used in a variety of industries such as the textile industry and the recycling industry. In these industries, precise alignment and preparation of fibers is essential to produce a quality end product.

Main faults of the machine and troubleshooting methods

- Quality of Finished Products Cannot Meet Requirements

Check whether all spacing settings meet specifications and inspect the stabbing roller rack for inverted or damaged teeth. - Fiber Contains Excessive Impurities

Examine the air duct and fan outlet for blockages, and clean accumulated fibers and dust to restore proper suction. - Machine Noise

Tighten the frame positioning bolts, check the installation foundation for unevenness, and ensure the bearing seat bolts on the stabbing roller are secure. - Chain Falling Off

Inspect whether the sprockets are aligned; adjust their position to ensure they are in a straight line.

Conclusion

With its efficient opening, carding, cleaning, and fiber output processes, the Fiber Carding Machine provides a reliable and cost-effective solution for recycling and processing a wide range of textile materials. Its stable performance, wide material compatibility, and high output make it an ideal choice for textile factories, recycling plants, and non-woven production lines.

If you are looking for a durable and high-efficiency Fiber Carding Machine tailored to your processing needs, welcome to contact us for detailed specifications, model selection, and the best quotation.