The Copper Wire Recycling Machine adopts a dry and eco-friendly crushing process to efficiently separate copper and plastic from discarded wires and cables. Through crushing and gravity separation techniques, the machine ensures a high-purity separation rate of over 99%.

With a processing capacity ranging from 300 kg/h to 2000 kg/h, it is well-suited to meet diverse production requirements. This equipment delivers clean separation, high efficiency, and energy-saving performance, making it an ideal solution for wire recycling operations.

Advantages of scrap copper wire recycling machine

- Wind-assisted gravity separation technology. Shuliy copper wire recycling machine adopts advanced wind-assisted gravity separation technology. By controlling the speed and direction of the air flow, copper and plastic are separated efficiently and cleanly.

- Up to 99% separation rate. The machine maximizes the overall efficiency of the recycling process, ensuring a separation rate of more than 99% for copper and plastic.

- Processing capacity 300 kg/h-2000 kg/h. The machine is available in five models to meet the needs of different processing capabilities.

- Saving energy and protecting environment. The machine is environmentally friendly. It does not require the use of fire, water or chemicals to separate copper and plastic, so it does not pollute the environment.

- Easy to operate. The machine adopts simple and friendly panel, PLC control system. It can be operated by only one worker and requires no complex technical knowledge or skills.

- Integrated structure. Customers can plug in the power supply to use the machine after purchase.

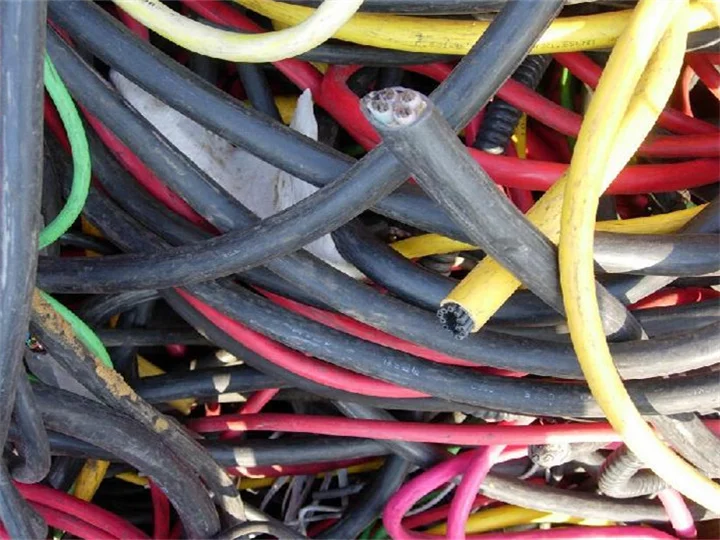

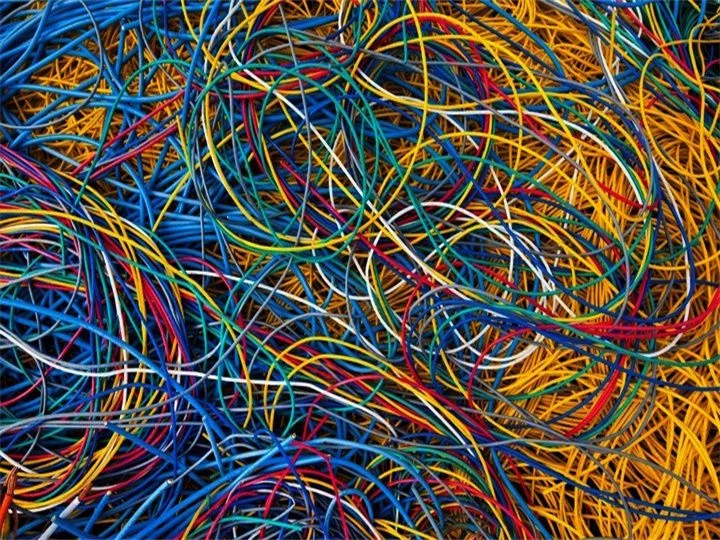

What are the materials used in cable wire recycling machines?

The cable wire recycling machine from Shuliy Recycling Machinery is capable of processing a variety of materials, such as copper wires and cables, copper wire in factory waste, copper wire in construction waste, copper wire in waste electrical appliances, copper wire in waste electronic products, and so on.

If you are not sure whether your material can be processed by our cable wire recycling machine, please feel free to ask us.

What can be done with recycled copper and plastic?

By using a scrap copper wire recycling machine, we can efficiently separate copper and plastic. For copper, we can sell it to material trading markets, copper processing plants, waste recycling stations, etc. Plastic can be granulated into other products, or remade into plastic threads.

Working process of waste copper wire recycling machine

The working process of the Shuliy waste copper wire recycling machine typically involves several key stages. Here is an overview of its typical operational process:

- Feeding and crushing

- Various types of waste copper wires or cables are fed into the machine and crushed into small granules to facilitate the separation process.

- Conveying and dust removal

- The crushed materials are transported through the system while the dust removal unit collects any dust or impurities, ensuring a clean working environment.

- Gravity separation and screening

- The machine uses gravity separation to effectively separate copper from plastic. The separated copper is then screened to ensure high purity.

- Control system and operation

- An integrated control system allows operators to monitor and adjust the process easily, ensuring smooth and efficient machine operation.

- Final output separation

- The machine achieves clean separation of copper (or aluminum) from plastic insulation, delivering high-purity recycled metal ready for reuse.

Equipment structure of scrap copper wire granulator machine

The main equipment of Shuliy scrap copper wire granulator machine includes crusher, air separator, vibrating screen, dust collector, electric control cabinet, conveyor, front vibrating screen bed (copper outlet), rear vibrating screen bed (plastic outlet).

Recycling copper wire machine technical specifications

| Model | Power(kw) | Output(kg/h) | Floor Space(㎡) |

| XYN-600 | 42 | 300 | 11 |

| XYN-800 | 58 | 500 | 15 |

| XYN-1000 | 99 | 800 | 22 |

| XYN-1600 | 136 | 1500 | 30 |

| XYN-2000 | 198 | 2000 | 50 |

Above are the parameters of 5 hot-selling cable wire granulator machines of our company. In addition, we also have other recycling copper wire machines for sale with different capacities. If you have any special requirements, you can contact us.

Copper wire recycling machine price

The price of a copper wire recycling machine can vary depending on various factors, including the brand, model, capacity, and features of the machine. Additionally, market conditions, geographical location, and the supplier or manufacturer can also influence the price.

The price range for a basic cable wire recycling machine could start from a few thousand dollars for smaller, more basic models, while larger, more advanced industrial-scale machines could cost tens of thousands of dollars or more.

For the most accurate and up-to-date pricing information, please contact us.

Welcome to choose shuliy as your copper wire manufacturing machine supplier

- Professional manufacturing capability. Shuliy is a company specializing in metal equipment recycling, with its own research and development team. In addition to the cable copper wire recycling machine, there are scrap metal baler, metal shredder machine, metal chips briquetting machine.

- Upgraded cable copper wire recycling machine. Unlike the traditional “wet separation method”, Shuliy’s cable copper wire recycling machine is an environmentally friendly dry crushing method, which will not pollute the environment.

- One-year warranty period and lifetime after-sales service. Shuliy not only provides one-year warranty service, but also provides customers with technical support, on-site installation and other services, focusing on customer purchase experience and use experience.

Conclusion

The Copper Wire Recycling Machine offers a reliable, efficient, and eco-friendly solution for recovering valuable copper from waste cables and wires.

Its high separation rate, customizable processing capacity, and user-friendly operation make it an ideal choice for recycling plants and scrap processing facilities.

If you’re looking to enhance your recycling efficiency and maximize copper recovery, feel free to contact us for more information or to get a quote tailored to your needs.