Gantry shear, which is one type of metal shearing machines, can efficiently shear and crush all kinds of metal sheets thus replacing manual dismantling, reducing production costs and improving recycling efficiency. Solid structure and powerfully shear force. What’s more, compared with alligator shears and tiger head shears, gantry shears are more suitable for cutting longer metal scrap.

Various Features of Gantry Shears

- Hydraulic drive. Shuliy’s hydraulic gantry shears use hydraulic system, stable and reliable operation, low noise, and high productivity.

- Long service life. Hydraulic system in the pressure cylinder closed strong, year-round use does not leak pressure and oil leakage, durable.

- Solid and safe structure. Adopting the whole welded solid open structure, which can make the machine body keep enough steel, and at the same time have the most convenient operation space.

- Powerful function. It can be applied to material bending, flanging, thin plate stretching, fine punching, and cold extrusion of metal parts.

- Adjustable pressing force and lifting height. It supports the adjustment of pressing force during the pressing process without overloading, and realizes the requirements of pressure preservation and time delay of each working step in the pressing process.

- Energy saving and environmental protection. Low oil pump displacement and low motor power, so it is power saving, energy saving.

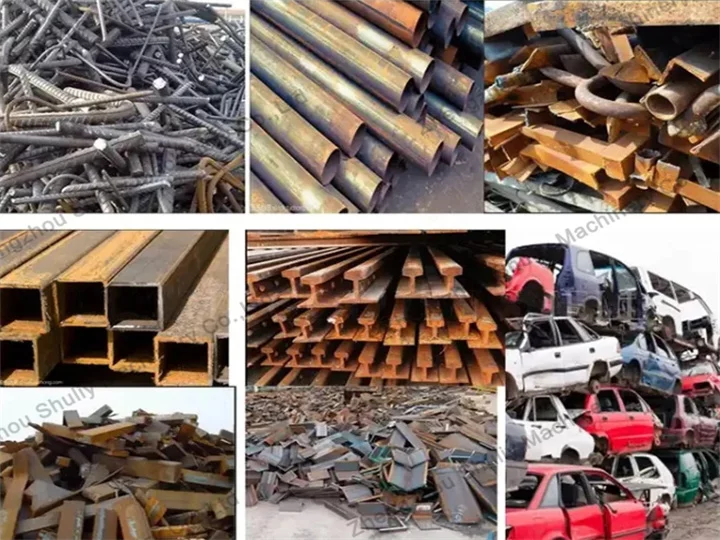

What Materials Can Gantry Shear Machine Handle?

Metal shear machine has a wide range of applications and can be used as processing equipment for metal recycling and processing units, as well as metal shearing and processing equipment for furnace processing in factory casting workshop and mechanical construction industry.

Metal shear cutter can specifically deal with metal, iron, cast iron, thin iron, thin iron, light material, steel, color steel tile, scrap steel, scrap iron, aluminum alloy, channel steel, angle steel, angle iron, copper plate, metal plate, aluminum profiles, scrap steel, aluminum plate, iron plate, steel plate, round steel and other various metal materials.

If you are not quite sure if your material is capable of using the sheet metal shear machine, feel free to contact us. We will provide you with rationalized suggestions and solutions.

Many Types of Gantry Shears for Sale

| Model | Shearing Cylinder(T) | Pressure Cylinder(T) | Material Box Size(MM) | Hydraulic System Max Working Pressure(Mpa) | Number of Cuts(Adjustable) |

| SL-500 | 500 | 85 | 6000*1500*650 | 28 | 3-5 time /min |

| SL-630 | 630 | 210 | 6000*1500*800 | 28 | 3-5 time /min |

| SL-800 | 622 | 220 | 8000*1800*1200 | 28 | 3-5 time /min |

| SL-1000 | 1000 | 344 | 8000*1900*1200 | 28 | 3-5 time /min |

Above is the information of some model parameters of our gantry shears for sale. If you want to know more information about shears for cutting metal or have other handling capacity, please feel free to contact us. We can provide customized service according to your individual needs.

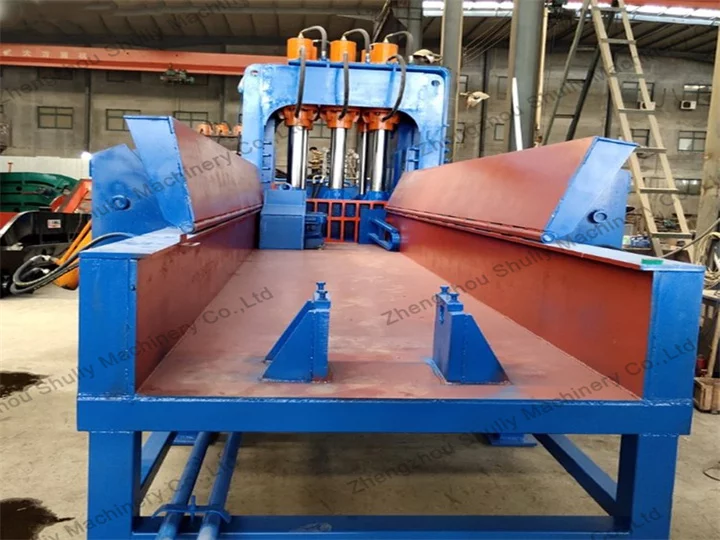

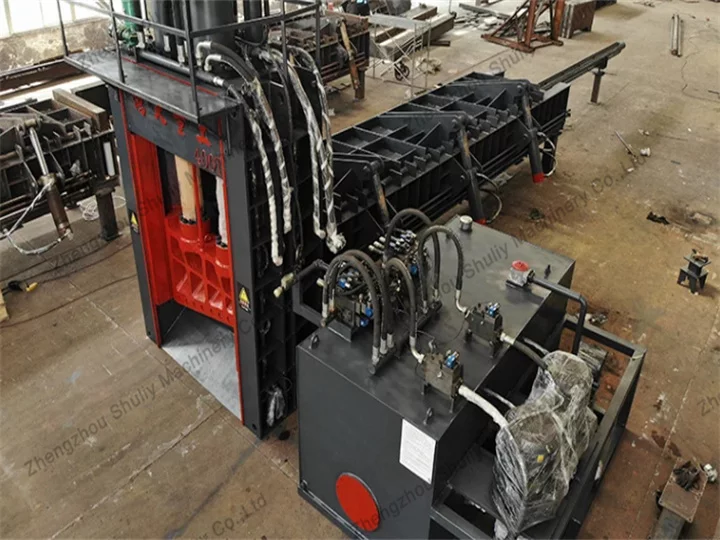

Structure of Metal Shear Machine

The hydraulic gantry shear is mainly composed of a frame, tooling system, hydraulic system, driving system, control system, feeding system, discharging system and other parts.

The body of the whole equipment is welded with high-strength steel, which is sturdy and durable. And with support legs and shock absorbing device to stabilize the hydraulic sheet metal shear, so that it is not easy to vibrate in the shearing process.

In addition, the equipment is equipped with electrical control cabinet, sensors to monitor and control the operation of the shear. And, it is equipped with overload protection, emergency stop button and other safety protection devices to ensure the safe operation of the equipment.

Hydraulic Gantry Shear’s Working Process

Feeding

Place the metal material to be sheared on the working table of the shear.

Positioning

Fix the material in the correct position using the positioning device.

Shear

High pressure fluid is supplied through the hydraulic pump to push the piston. The piston drives the upper blade downward through the connecting rod mechanism. The upper blade cooperates with the fixed lower blade to apply shearing force to the material to complete the shearing action.

Reset

After completing a shear, the hydraulic system releases the pressure, and the piston returns, driving the upper blade back to the initial position.

Related Configuration Machine: Grab Crane

Grab crane consists of several jaws which can be opened and closed by hydraulic or wire rope control. It is a specialized crane for grabbing and handling bulk materials (such as metal, coal, wood, etc.). It is one of the important supporting equipment in the operation of the metal cutting shear.

By working together with gantry shear machine, they will greatly improve the automation level, speed up the production process, and save labor, material, and financial resources.

Other Types of Metal Recycling Equipment

In addition to the type of gantry shear, Shuliy has also designed other types of metal shears, including alligator shears and tiger head shears.

What’s more, as a well-known manufacturer of recycling machinery and equipment, Shuliy has metal balers, metal shredders, and so on for sale.

If you are interested, please feel free to consult us. We can provide customized solutions for your recycling project, as well as door-to-door installation and technical guidance.