Advantages of Foam Granulation in Various Industries

When it comes to material processing and preparation in manufacturing, opting for foam granulation technology holds numerous advantages. This technology showcases significant value and diverse applications across various industrial domains. Let’s delve deeper into the advantages of foam granulation technology and its applications in different sectors.

Diverse Applications Across Industries

Foam pelletizing technology finds extensive applications across various fields. Whether in pharmaceutical drug preparation, plastic processing, or in industries such as chemicals and agriculture, the presence of foam pelletizing technology is evident. Its flexibility and customization make it a crucial component in multiple industrial processes, enhancing production efficiency and product quality across different sectors.

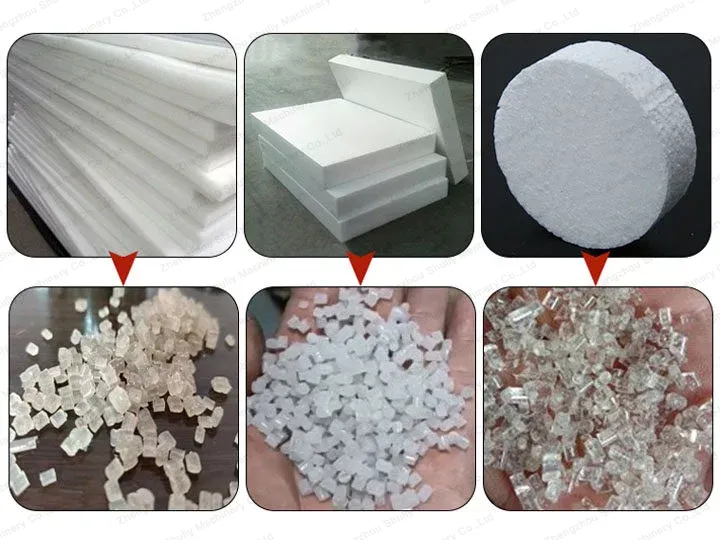

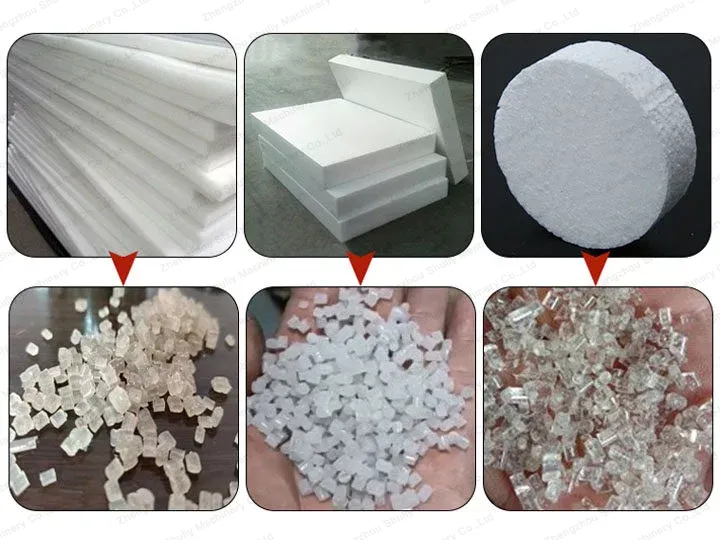

Enhanced Material Utilization

Foam granulation technology is an efficient method for maximizing raw material utilization. Using a foam granulator to process materials into uniform and controllable-sized particles helps maximize material utilization significantly. This precise processing method reduces material wastage, saving costs and improving production efficiency. In industries like pharmaceuticals and chemicals, this optimized material utilization is crucial for maintaining product quality stability and cost control.

Improved Product Quality

The application of foam granulation technology can enhance the quality and performance of end products. By controlling the process parameters of the foam granulator, precise particle size, shape, and density adjustments can be achieved, ensuring consistent product characteristics. In the production of plastic goods, employing foam granulation technology results in uniform and stable particles, ensuring higher product quality and reliability.

Innovation in Material Development

Foam granulation technology is not limited to traditional materials; it also fosters the development and innovation of new materials. By adjusting operational parameters and material formulations in foam granulators, researchers can explore novel methods for creating new materials. This flexibility and adjustability bring forth new possibilities in material science, aiding in the development of new materials with specialized properties and applications.

Reduced Environmental Impact

Adopting EPS granulation technology helps minimize adverse environmental impacts. Compared to traditional processing methods, the minimal waste and lower energy consumption during EPS granulation make it a more eco-friendly choice. This aligns with the current emphasis on sustainable development, attracting more enterprises to incorporate EPS granulation technology into their production processes.

In a word, foam pelletizing technology, with its advantages in enhancing material utilization, optimizing product quality, fostering innovative development, reducing environmental impact, and its diverse applications across industries, emerges as a pivotal processing technology in many sectors. With increasing demands for efficiency and sustainability, foam granulation technology is expected to witness broader application across various industrial domains, bringing forth more opportunities for innovation and development in the manufacturing and production realms.