The Alligator Shear is a heavy-duty cold-cutting machine engineered for metal recycling. It effortlessly shears rounds, squares, angles, plates, pipes and end-of-life vehicles into smaller, furnace-ready pieces.

Driven by a 250-ton hydraulic system with a 1,200 mm blade width and a 22 kW motor, this Alligator Shear delivers 8–12 cuts per minute, weighing in at 4,100 kg—making it the high-capacity, long-life solution for scrap yards, dismantling centers, and foundries pursuing efficient, eco-friendly recovery.

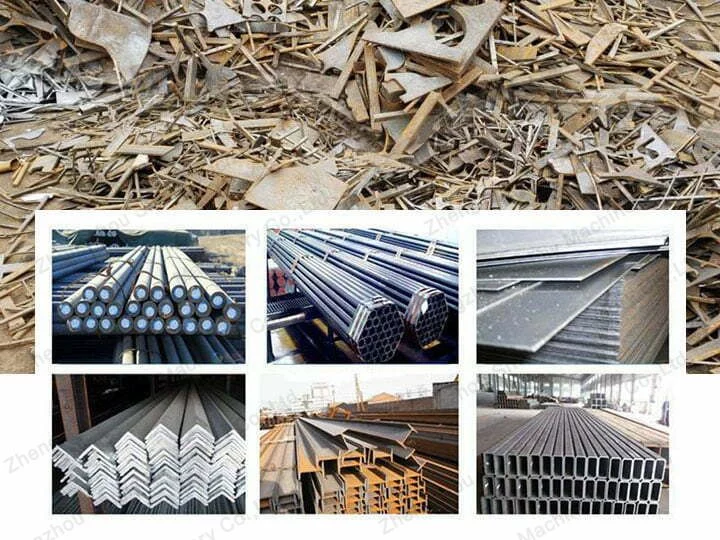

Application of metal shearing machine

The metal shearing machine is widely used for cutting scrap metals of various shapes, including round bars, plates, pipes, angles, and channels. It can also handle non-ferrous metals like copper, aluminum, and iron.

With strong cutting performance, it is ideal for recycling plants, vehicle dismantling yards, and smelting industries, supporting efficient processing and sustainable waste management.

Benefits of metal shear cutter

- Multiple blade sizes available, including 400 mm to 1200 mm, to meet different cutting needs.

- Hydraulic system ensures smooth, stable, and efficient cutting performance.

- Suitable for various metals like steel, aluminum, and copper, offering wide material compatibility.

- Built with high-strength alloy steel for durability and long service life.

- Simple controls and mobile design make it easy to operate and relocate as needed.

What are the types of metal shears?

Alligator Shear

The alligator shear, also known as a crocodile shear, gets its name from its jaw-like design resembling an alligator’s mouth.

It is widely used to cut and downsize large metal objects such as steel beams, rods, pipes, and various scrap metals from cars, appliances, and industrial waste into smaller, manageable pieces for recycling or further processing.

Tiger Head Shear

Named for its tiger-head-like shape, the tiger head shear is used for shearing, pressing, and flanging various steel profiles and metal materials.

It can also press and mold powders, plastics, fiberglass, insulation materials, and rubber.

Shuliy’s alligator shear and tiger head shear in the external shape of its equipment is different, but the structure of the equipment and the principle of operation are the same. They are both hydraulic drive technology to realize the metal material shear machinery and equipment.

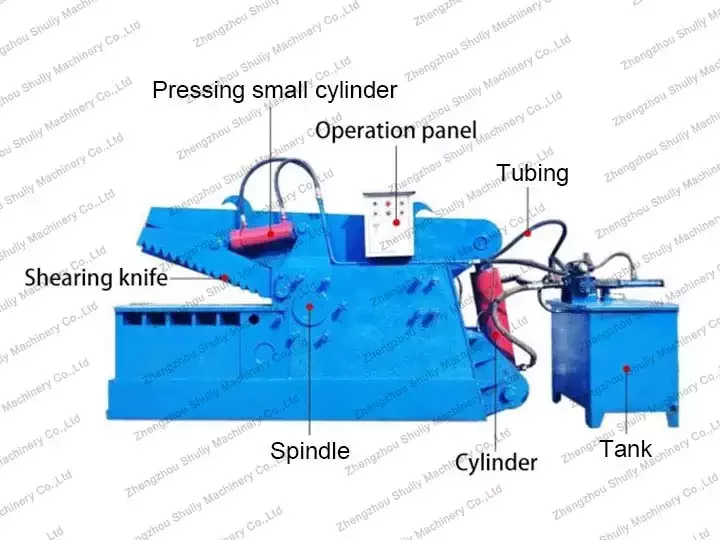

Key parts of the metal shearing machine

Hydraulic metal shear consists of shear cylinder, shear knife, slider press knife, lower knife seat, press cylinder and so on.

- Shear knife: made of high-strength alloy steel, with high hardness and wear resistance, to ensure shear precision.

- Hydraulic system: the hydraulic system provides power for cutting to ensure that the shearing process is precise, smooth and efficient.

- Anvil: the metal being cut is placed on a sturdy anvil or bed against which the blades come into contact during the cutting process.

- Control panel: operators can control the metal shear machine’s operation, including blade movement and cutting force, through a control panel.

How does the hydraulic alligator shear work?

The hydraulic alligator shear operates through a combination of hydraulic pressure and mechanical leverage to efficiently cut metal materials. The machine features upper and lower jaw-like blades (similar to an alligator’s mouth) and is powered by a hydraulic system that drives the shearing motion.

Here’s how the shearing process works step by step:

- Hydraulic system activation: A hydraulic pump creates pressure, which is controlled through an electromagnetic reversing valve to manage the oil circuit and the movement of the cylinder.

- Material positioning and locking: The material is pre-pressed and locked into position. The cylinder applies force via a lever mechanism to push upward, allowing the upper blade to press down and hold the material securely.

- Shearing action: With continuous pressure from the main cylinder, the upper movable blade descends while the lower fixed blade remains in place. The two blades work together to shear the material precisely at the designated cut-off point.

This efficient cutting mechanism ensures stable performance and is widely used in scrap metal processing, recycling yards, and steel fabrication industries.

Hydraulic alligator shear for sale parameters

| Model | SL-1200 |

| Blade working width | 1200 mm |

| Cutting pressure | 250 tons |

| Power | 22 kw |

| Oil pump | “80*1 |

| Number of cuts | 8-12 times/min |

| Voltage | 380V/3PH,50Hz |

| Weight | 4100 kg |

Above is one of the hot selling alligator shears from Shuliy Recycling Machinery. Besides this machine, we have other styles and sizes of hydraulic sheet metal shears for sale.

If you want to know more information such as parameter and price , please feel free to contact us. And we can also provide you with customized services.

Welcome to choose Shuliy as your hydraulic metal shear manufacturer

- Advanced technology. Since 2011, Shuliy insists on researching and developing the production of recycling equipment, constantly improving and upgrading the machines to increase the precision and efficiency.

- Rugged and durable equipment. We are committed to providing quality and reliable equipment for your cutting needs. You can expect durable, superior performance from the equipment.

- Full support. Our professional support team is here to help you every step of the way, and the equipment comes with a one-year warranty.

- Customized service. We can provide customized equipment to meet your individual needs.

Are Shuliy’s sheet metal shears safe?

Shuliy’s sheet metal shear, like most industrial machinery, are designed with safety in mind. However, the safety of these machines ultimately depends on how they are used, maintained, and operated by individuals. Here are some considerations regarding the safety of the Shuliy metal shear machine:

- Built-in safety features like emergency stops, guards, and interlocks help prevent accidents.

- Operators should be properly trained in machine use and safety procedures.

- Regular inspections are necessary to detect and fix wear or malfunctions promptly.

Metal recycling related equipment

Conclusion

With its powerful hydraulic system, simple structure, and reliable cutting performance, the Alligator Shear is an essential tool for scrap metal recycling and industrial metal processing.

Whether you’re handling steel, aluminum, or dismantling automotive and structural scrap, this machine ensures clean cuts, high efficiency, and long service life.

Contact us today to get a customized solution for your metal cutting needs.