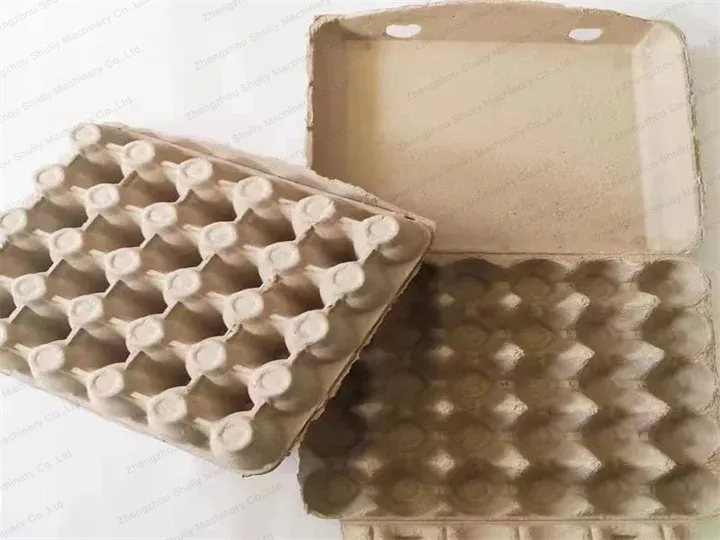

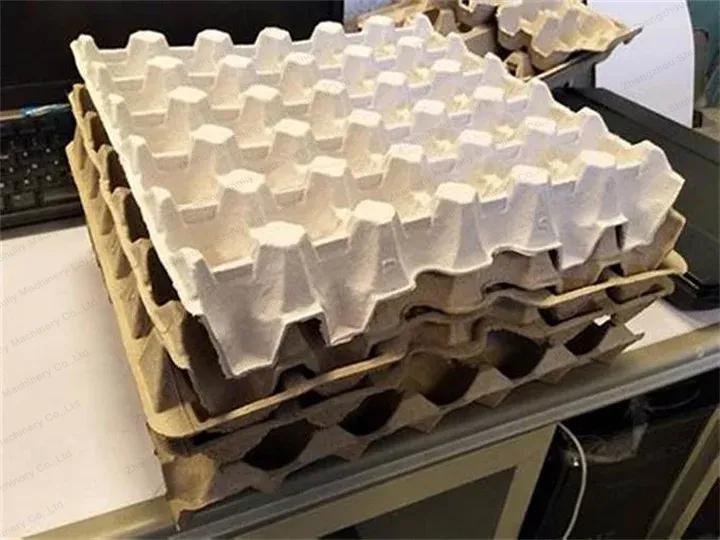

Egg tray making machine, also known as an egg carton machine or egg box making machine, is specialized equipment for producing egg trays or cartons used in packaging and transporting eggs.

With a capacity of 1000–7000 pcs/h, it meets the needs of poultry farms, egg processing plants, and paper product manufacturing facilities, offering efficient, eco-friendly, and customizable production solutions.

Raw materials that can be used to make egg cartons

Egg cartons, also known as egg trays or egg packaging, are most commonly produced from recycled paper pulp, making them an eco-friendly and cost-effective packaging solution.

The main raw material is waste paper, which can come from a wide range of everyday and industrial sources. By utilizing these materials, manufacturers can reduce environmental impact while lowering production costs.

Common raw materials include:

- Old newspapers

- Cardboard

- Magazines and catalogs

- Office paper

- Junk mail

- Paperboard

- Paper packaging

- Telephone directories

- Paper waste from industries

These waste paper materials are processed into pulp and molded into sturdy egg cartons, ensuring both protection for the eggs and sustainability for the environment.

Paper egg tray making machine advantages

- Versatile production – Capable of making standard egg trays as well as fruit trays, seedling trays, and other paper products by simply changing the mold.

- Easy operation – User-friendly design allows operators to start production quickly without complex training.

- Customizable options – Can be tailored to meet specific production needs and product specifications.

- Wide output range – Offers production capacities from 1000 pcs/h to 7000 pcs/h to suit different scales of operation.

Different models of egg tray making machines for sale

Small Egg Tray Making Machine

We offer a wide range of different models of egg tray making machines for you to choose from.

The small egg tray making machine with a capacity of between 1000 and 1500pcs/h is suitable for small scale production and offers an excellent price/performance ratio.

| Model | Capacity | Power | Voltage | Paper consumption | Water consumption | Size(molding machine) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 80kg/h | 160kg/h | 2600*2200*1900mm |

Medium-sized Egg Tray Making Machine

If you need a higher capacity, a medium-sized egg tray making machine may be more suitable for you, with an output of 2,000 to 3,000pcs/h.

| Model | Capacity | Power | Voltage | Paper consumption | Water consumption | Size(molding machine) |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 200kg/h | 400kg/h | 2900*1800*1800mm |

Large-sized Egg Carton Machine

In addition, we offer fully automated egg tray making machines with outputs of up to 4,000 to 7,000 trays per hour, which are ideal for large-scale production needs.

| Model | Capacity | Power | Voltage | Paper consumption | Water consumption | Size(molding machine) |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 480kg/h | 960kg/h | 3200*2300*2500mm |

What is the egg tray making process?

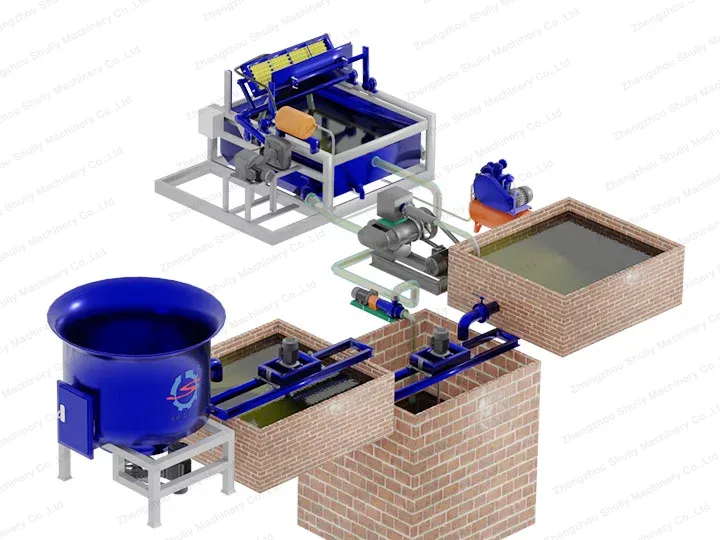

The egg tray making process involves several steps, starting from the collection of raw materials to the final production of egg trays. Here’s an overview of the typical egg tray making process:

- Collection of raw materials – Waste paper such as old newspapers, cardboard, and magazines is collected and sorted for recycling.

- Pulping – The waste paper is soaked in water and processed in a paper pulper machine to create a uniform pulp slurry free from impurities.

- Molding – The refined pulp is fed into an egg tray molding machine, where molds shape it into trays or cartons.

- Drying – The wet trays are dried using a conveyor or rack system with applied heat to remove moisture and solidify their form.

Egg tray machine price

The price of an egg tray machine can vary significantly depending on several factors, including the type and capacity of the machine, its brand, quality, and additional features or customization options.

- Small scale egg tray machine: small, manual machines with lower production capacity (around 1000-1500 trays per hour) can range in price from approximately $5,000 to $10,000 or more.

- Medium scale semi automatic egg tray machine: medium-sized, semi-automatic machines with higher production capacity (around 2000-3000 trays per hour) typically cost between $15,000 and $30,000.

- High capacity egg tray machine: fully automatic machines with even higher production capacity (around 4000-7000 trays per hour) are usually more expensive, with prices starting at $30,000 and going up significantly based on capacity and features.

Related parts of the egg tray making machine

Egg tray making machine is a complex piece of equipment that contains several key components, each of which plays an important role in the production process. Below are some of the main components associated with the egg tray making machine and their functions:

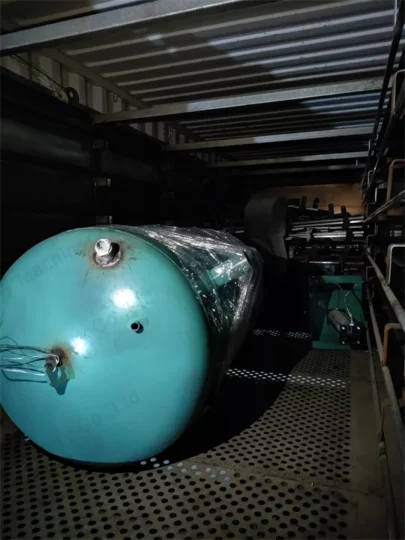

Vacuum Pump

The main function of the vacuum pump is to generate negative pressure through the stainless steel mesh of the mold to draw out the excess water and discharge it into the sink. This helps to ensure that the egg tray has the proper moisture level during the molding process.

Air Compressor

The air compressor blows the trays from the suction mold to the transfer mold through a solenoid valve and then blows the trays from the transfer mold to the mesh belt or tray through another solenoid valve. This process helps to transfer the egg trays from one working stage to the next.

Pulp Pump

The function of the pulp pump is to pump the pulp from one stock tank to another through its centrifugal force. This ensures that the pulp is always in the proper position for use in the manufacturing process.

Paper Pulper Machine

The pulper spins water through an impeller and then uses centrifugal force to beat the pulp by hitting the waste paper and water against a spoiler on the cylinder. This is a key step in the preparation of the pulp, converting the waste paper into a stock suitable for the manufacture of egg trays.

Where to buy egg carton making machine?

You can buy egg carton making machine through online marketplaces, directly from manufacturers, local industrial machinery suppliers, trade shows and exhibitions, etc. As mentioned earlier, Shuliy Recycling Machinery is one of the manufacturers that offer paper egg tray making machines and paper recycling machines. You can visit our website or contact us directly to inquire about our product offerings, pricing, and any specific requirements you may have.

Egg tray drying method

There are several methods for drying egg trays, and the choice of method often depends on the scale of production and available equipment. Here are some common methods for drying egg trays.

- Air drying – Low-cost method where egg trays are dried under sunlight, but drying time depends on weather.

- Drying in dryers – Uses controlled temperature and humidity for fast, weather-independent drying, ideal for medium to large-scale production.

- Custom drying rooms – High-volume method using conveyor tunnels with controlled heat (180–200°C) and ventilation for fast drying, but requires specialized facilities.

- Multi-layer metal dryers – Large-scale, high-efficiency system where trays move through multiple heated layers, offering rapid drying but needing substantial equipment.

The choice of drying method should consider production requirements, available equipment, budget, and other factors.

Conclusion

Our egg tray making machine offers efficient molding with a flexible production capacity ranging from 1000 to 7000 pcs per hour, combined with multiple drying options such as air drying, drying ovens, custom drying rooms, and multi-layer metal dryers to suit various production scales and environments.

Choosing our egg tray machine means investing in an energy-saving, sustainable, and high-output solution that helps you step confidently into the future of environmentally friendly packaging manufacturing.