An EPS foam granulating line is mainly suitable for processing industrial waste, construction waste, packaging materials, logistics waste, etc.. By crushing, melting, granulating and cutting waste foam into small particles, EPS foam pelletizing line can efficiently obtain foam products that meet international quality standards. As the key equipment of EPS foam granulation line, the processing capacity of foam granulation machine can reach 150-300 kg/h. What’s more, we can also design personalized solutions according to your processing capacity and special needs, welcome to contact us at any time.

Uses of Foam Pellets

EPS pellets made with EPS foam granulating lines have many uses. EPS pellets can be used to make express foam, fresh foam, shockproof foam, building insulation material, industrial sound insulation material, cold insulation material, wall material, packaging material, flooring material, and so on.

Why Recycle Plastic Foam?

Plastic foam is a lightweight, strong material commonly used for packaging, insulation, and construction. Recycling waste plastic foam through Shuliy EPS foam pelletizer production line can bring a series of economic benefits, ecological benefits and social benefits.

- Reduce environmental pollution: waste foam materials not only takes up space, but also they are difficult to degrade, which will increase environmental pollution.

- Save resources: by recycling waste foam materials, the need for virgin plastics can be reduced and thus recycled.

- Economic benefits: through the continuous development of recycling technology, recovery and reuse of waste foam can reduce production costs and improve earnings.

Advantages of Shuliy Foam Recycling Equipment

- High degree of automation: the polystyrene recycling equipment adopts an automatic control system, except for feeding and discharging, basically no other personnel.

- High recovery rate: they can increase the recovery rate of waste foam up to 95%.

- High production efficiency: as the core equipment of EPS foam granulating line, the production capacity of foam granulator is 150-300 kg/h, which has a high disposal capacity.

- Strong and durable: the equipment of whole production line are entirely made of high-quality steel, so they have a long service life.

- Broad application: they can recycle various types of foam, including EPS, EPE, XPS, and so on.

- Customized service: Shuliy can be equipped with more suitable production lines and machines according to customers’ raw materials, output and regions to meet customers’ individual needs.

Waste Foam Granulating Process

EPS/EPE foam granulating line equipment mainly includes foam shredder machine, EPS foam pelletizing machine, cooling pool, pellet cutting machine, and storage tank.

Its process is mainly to send the waste EPS foam material into the foam shredder machine to break into small pieces. A EPS foam pelletizing machine is then used to extrude the melted foam material into continuous strips. Next, the extruded strips are cooled through a cooling pool. Finally, the extrusion strips are cut into particles of uniform size by a pellet cutting machine and stored.

In the following, we will give you a more detailed introduction about the main equipment of EPS/EPE foam granulating line. If you want to know more details about the equipment, please contact us.

Specific Equipment Introduction of EPS Foam Granulating Line

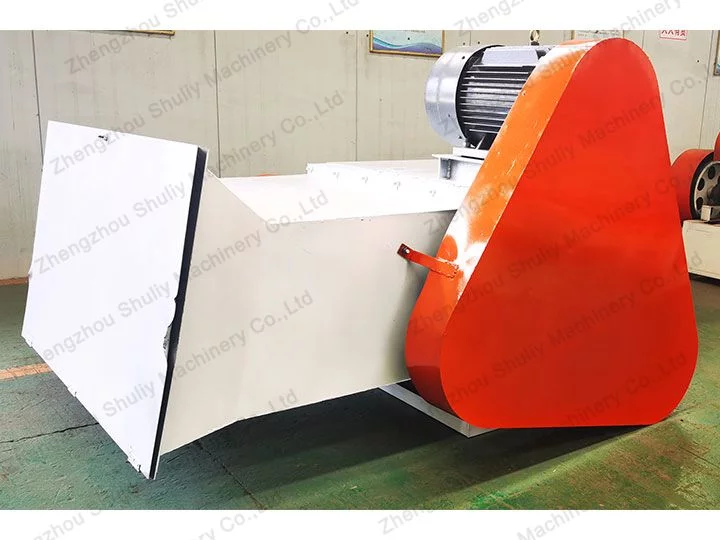

EPS Foam Shredder Machine

The EPS foam crushing machine is the first machine in the EPS foam granulating line. Large pieces of waste foam make it difficult to enter the foam pelletizer system. Therefore, we need to pulverize the large pieces of foam with an EPS foam shredder beforehand.

Shuliy foam crushing machine meets the needs of large processing capacity, which can handle 250-500 kg/h. Moreover, it is a horizontal large-capacity feed port design, which is simple operation and labor-saving.

Foam Granulator Machine

The foam granulator machine can melt the EPS foam into a liquid and extrude the molten EPS foam into a long strip. Shuliy plastic foam granulator can reach a processing capacity of 150-300 kg/h. It uses a dual reducer for a higher reduction ratio and increased torque output. And, the configured electric mold can realize non-stop network change, which greatly saves the operation time.

Cooling Tank

The cooling tank cools the material in the form of a long strip. The temperature of the material just coming out of the EPS pelletizing machine is very high. Therefore, we use cooling equipment to cool the material. It will facilitate the subsequent cutting.

Pellets Cutting Machine

The pellet cutter cuts the material in the form of a long strip into the desired size. The size of the foam pellets can be adjusted to suit your needs and the particles are uniform in size.

Parameters of EPS Foam Pelletizing Line

| Brand | Shuliy |

| Material | Waste EPS、XPS、EPE foam |

| Capacity | 150-300 kg/h |

| Main equipment | Foam shredder, EPS pelletizer |

| Finished products | Recycled EPS pellets |

| Warranty | 12 months |

How to Find a More Suitable Foam Granulating Line Manufacturer?

You can search through local dealers, exhibitions, e-commerce platforms, professional equipment markets, or visit the manufacturer’s official website for equipment information and contact information.

Shuliy is a manufacturer with more than 20 years of experience in developing plastic recycling equipment. We are constantly innovating to improve the performance of our recycling equipment and increase environmental sustainability.

Do you need a high-quality EPS foam granulating line to recycle waste foam? Welcome to contact us anytime, we will reply you within 24 hours.