Foam shredder machine is a piece of foam recycling equipment used to break large, lightweight foam materials into small pieces or particles. The processing capacity of Shuliy foam shredder machine is 250-500 kg/h, and it has 4 types for you to choose. What’s more, the equipment structure is simple, easy to operate, and low noise.

Advantages of Foam Shredder Machine

- High recovery efficiency. The foam shredders facilitate the reduction of foam waste into manageable particles, enabling efficient storage, transportation, and recycling.

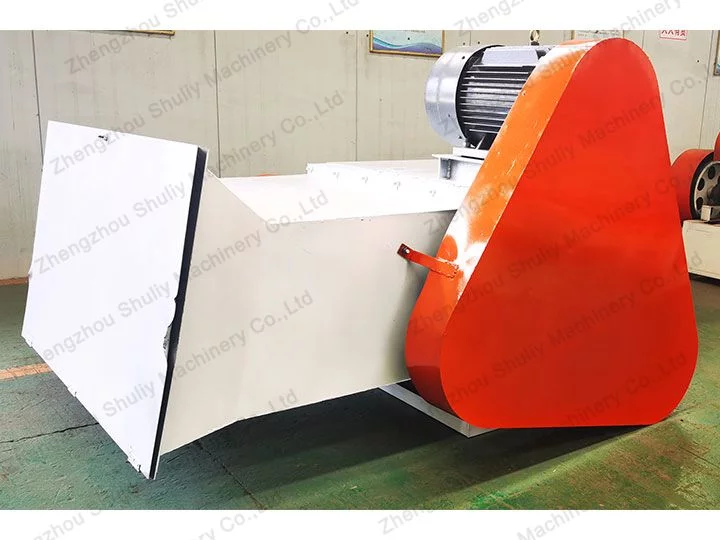

- Large capacity horizontal feed port. The feed opening of the Shuliy foam crusher is flush with the ground, which allows the operator to push the material indirectly.

- Double dust removal device. The function not only reduces the dust in the working process but also makes the finished product cleaner.

- Sturdy and durable. Compared with others, the shaft of our shredder adopts a solid shaft. It is also made of high-strength alloy steel to ensure its sharpness and durability.

Applications of Foam Crushing Machine

Foam crushing machine is suitable for crushing many kinds of plastic foam materials including EPS, EPS, EPP, EPE, PU, and so on. It is also suitable for pulverizing waste foam trimmings, packaging foam, disposable lunch boxes, extruded plastic boards, foam boxes, KT boards, and other products.

If you are not sure that our equipment can handle your raw materials, we can help to resolve your doubts.

parameters of Foam Crushing Machine

| Type | SL-800 | SL-1000 | SL-1200 | SL-1500 |

| Feed port size (MM) | 800*600 | 1000*600 | 1200*600 | 1500*800 |

| Power (KW) | 5.5 | 5.5 | 7.5 | 11 |

| Capacity (KG/H) | 250-300 | 300-350 | 400-450 | 450-500 |

The foam crushing machine is designed to handle different scales of foam waste, from smaller volumes to larger industrial quantities. If you have a different output, please consult us. We also can provide customized services for our customers.

What types of foam crushers does Shuliy have?

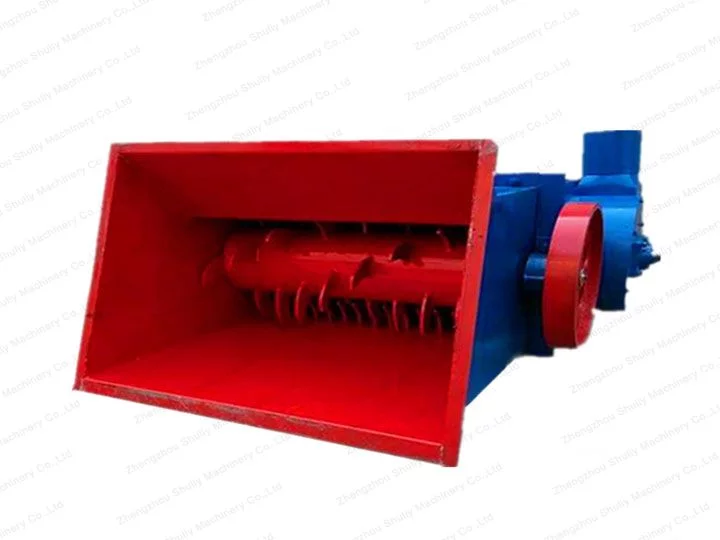

Single-shaft crusher

Using a rotating shaft with multiple blades, the foam is cut into small pieces by high-speed rotation of the blades.

Double-shaft crusher

It is made of two staggered rotating knife axes. The blades on the two axes work together to break the foam into small pieces by shear force.

How Does the Foam Shredder Machine Work?

The foam shredder machine mainly includes feeding hopper, rotary blade, screen and discharge port. As the foam materials are fed through the machine’s feed port, the blades effectively slice through the foam, reducing it to manageable sizes. The powerful motor delivers the necessary force to drive the cutting blades, enabling the machine to handle varying foam densities and sizes effectively.

Foam Shredder Machine Price Analysis

Investing in a commercial styrofoam shredder is a strategic move for businesses aiming to streamline waste management processes and enhance sustainability efforts. The SL-800, SL-1000, SL-1200, and SL-1500 models offer competitive pricing options, catering to diverse budgetary requirements.

The pricing ranges vary depending on factors such as power capacity, processing efficiency, and overall dimensions. The SL-800 model is positioned as a cost-effective solution for small to medium enterprises. The SL-1500 model, with its higher power capacity and throughput capabilities, justifies a slightly higher investment for larger-scale industrial operations.

What Can crushed Foam Be Used For?

- Packaging material: crushed foam can be used as packaging material, filler, or cushioning material. This protects fragile items or products during transportation.

- Fillers and Insulation: crushed foam can be used as filler or insulation to fill voids in walls, roofs, or other building structures.

- Manufacture of new products: crushed foam can be used to manufacture a variety of products such as furniture padding, floor cushions, and more.

- Environmental applications: crushed foam can also be used for environmental applications, e.g. as filler material in soil improvement or ecological engineering projects.

How to maintain foam crusher?

Proper maintenance can maximize the service life and performance of the foam crusher. How to maintain the foam crusher?

- After each use, clean the residual foam debris in the crushing chamber to prevent blockage or affect the cutting efficiency.

- Check the tool condition regularly. If the tool is seriously worn or damaged, it should be replaced in time.

- Check whether the wires, switches, etc. are damaged or safe to use.

- Periodically check whether fasteners such as screws and nuts are loose and tighten them in time.

- Ensure that the protective cover is intact and the emergency stop button is sensitive and reliable.