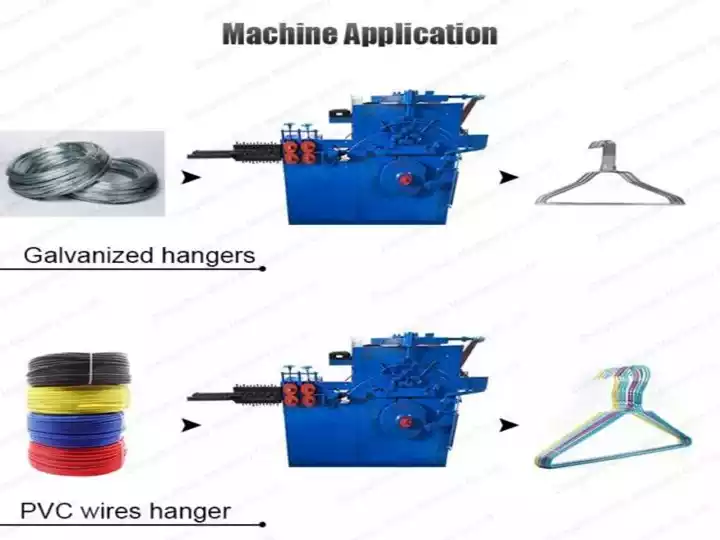

Hanger Making Machines are advanced automated equipment designed for efficient production of various hanger types, primarily used in the garment industry. These machines can handle materials like galvanized wire, plastic-coated wire, and aluminum, with a production capacity of up to 52 hangers per minute.

Equipped with CNC control systems and servo-driven feeding mechanisms, they offer high precision and flexibility, allowing easy customization of hanger shapes, sizes, and colors. With durable construction and simple operation, these machines are widely used in large-scale manufacturing and are trusted by clients worldwide.

Raw materials for making cloth hanger machine

Cloth hanger machines are versatile and can produce hangers from a variety of materials.

Common materials used for hanger production include 201 stainless steel, 410 stainless steel, aluminum alloy, plastic, electroplated wire, ordinary iron wire, coated wire, and aluminum wire.

If you’re unsure whether your raw material is compatible with our hanger making machine, feel free to send us the details of your material, and we’ll provide guidance on its suitability.

Clothes hanger making machine advantages

- Versatility in Production. Shuliy’s clothes hanger making machines are available in wire thicknesses ranging from 1.8-3 mm and can produce hangers in sizes ranging from 13-19 cm, thus meeting a wide variety of customer needs.

- High degree of automation. The machine’s automation system, driven by CNC technology and PLC programming, controls the entire hanger manufacturing process. Therefore, it can ensure precise and consistent hanger production.

- Durable Construction. The machine is constructed using robust materials, ensuring durability and long-term reliability.

- High Production Capacity. The machine has a fast production speed of up to 2,700 pcs/h, which greatly improves overall productivity.

- User-Friendly Operation. The machine is designed for user convenience, featuring simple, intuitive controls that simplify operations.

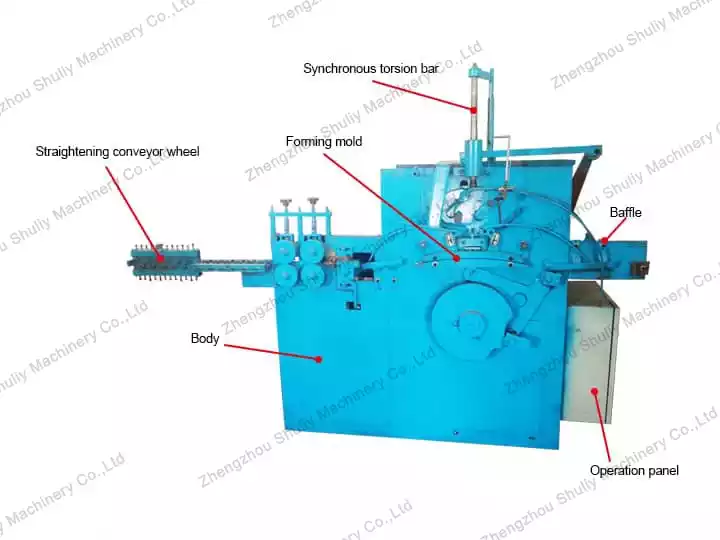

Clothes hanging machine structure

Clothes hanging machine mainly includes a frame, power unit, spindle, straightener, tractor, cutter device, hanger taking out the device, and hanger shaping mold.

The power unit is equipped with a control box which controls the power unit and is electrically connected to the inductor. The control box is equipped with a time counter. The frame is provided with a “U” shaped groove. The “U”-shaped groove is fitted with a movable plate for adjusting the height of the ticking mechanism.

How does the hanger making machine work?

The hanger making machine operates through a fully automated process to ensure precise and efficient production. First, the wire is fed into the machine’s straightening system to ensure smooth and accurate processing. Once straightened, the wire is cut to a preset length—automatically stopping at the correct point for consistent sizing.

The machine also allows quick mold changes to produce hangers of various shapes and sizes. After cutting, the wire moves to the forming section, where it is automatically bent and shaped into the desired hanger design.

Automatic wire hanger making machine for sale parameters

| Model | SL-PT-400 |

| Capacity | 30-45 pcs/min |

| Wight | 700 kg |

| Dimension | 1800x800x1650 mm |

| Power | 1.5 kw |

Above are the technical specifications of our hot selling hanger making machine. If you need this machine, please feel free to contact us, and we will reply to you as soon as possible.

Plastic hanger making machine price

The price of a plastic hanger making machine depends on several factors such as the brand, model, specifications, production capacity, and additional features. The cost of a coat hanger machine can also be influenced by the complexity of the machine, its automation level, and the materials used in its construction.

When considering the price of a plastic hanger making machine, it’s essential to evaluate the machine’s capabilities and features in relation to your production needs and long-term business goals. If you want to know the actual price of the machine, please feel free to contact us.

How to maintenance the hanger making machines?

- Regular cleaning

- Regularly clean the machine, removing any dust, debris, or residual materials that might accumulate during the production process.

- Lubrication

- Apply lubricants to the moving parts of the machine.

- Inspection and replacement of parts

- Conduct routine inspections to identify any worn-out or damaged parts. Promptly replace these parts with genuine components to avoid potential breakdowns.

- Tightening of fasteners

- Regularly check and tighten all nuts, bolts, and fasteners to prevent any loosening due to the vibrations generated during the machine’s operation.

- Calibration

- Periodically calibrate the hanger making machine to ensure precise and accurate production.

- Electrical system check

- Inspect the electrical system regularly, checking for any loose connections, damaged wires, or faulty components.

Hanger making machine production line

Our hanger making production line has become an indispensable equipment for hanger production line of enterprises pursuing high productivity and high precision.

A complete hanger production line mainly consists of a wire payoff machine, a hanger machine, a plastic spray gun, a plastic powder recycling chamber, a drying chamber and other equipment.

First, the prepared wire is made into the desired hanger shape. And second, the plastic powder is evenly sprayed onto the hanger surface for coloring. Finally, the hanger is dried to ensure that the plastic particles are firmly attached to the hanger surface.

Contact us now!

Our hanger making machine combines high efficiency, precision, and flexibility—ideal for producing a wide range of hanger types with different materials and specifications.

If you’re interested in improving your hanger production or want to know if your raw materials are suitable, contact us today for a free quote and expert guidance!