The industrial shredder machine can reduce the size of various solid waste materials, including plastic, rubber, wood, metal, cardboard, and more. Designed for demanding recycling and waste processing applications, this machine features a robust structure, high-torque cutting system, and low-speed operation to ensure stable and efficient shredding.

With a processing capacity ranging from 0.5 to 40 tons per hour, it meets the needs of both small-scale and large-scale operations in industries such as recycling plants, manufacturing facilities, and waste treatment centers.

What are the advantages of industrial shredder machine?

- It offers high crushing efficiency with capacities from 0.5 to 40 tons per hour, suitable for both small and large-scale operations.

- The modular bearing box design allows for quick and easy replacement of blades and internal components.

- Blade shapes can be customized to produce strips, flakes, or powder depending on processing needs.

- It delivers strong shredding power, handling both lightweight materials like paper and plastic and heavy materials like tires and car shells.

- A high-speed hard-tooth surface reducer ensures stable and efficient power transmission.

- The machine is made from high-quality steel with wear-resistant alloy blades for long-lasting durability.

- Intelligent PLC control enables automatic reverse during overloads, making operation safer and more user-friendly.

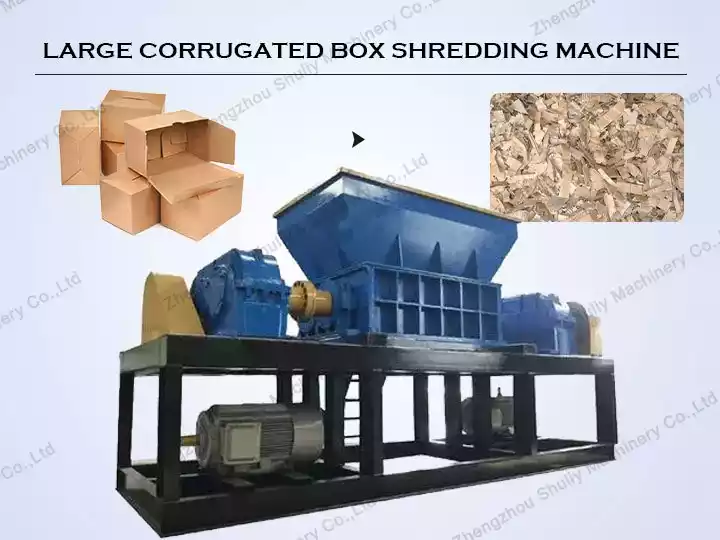

What raw materials can cardboard industrial shredder machine handle?

Industrial cardboard shredder is a kind of high efficiency, multi-function and practical mechanical equipment. It can handle all kinds of solid waste, including but not limited to waste paper, plastic, wood, metal, tires, etc. The following are the main areas where it can be applied and its specific application scenarios:

- Waste paper recycling: egg tray factory, printing plant, paper factory.

- Plastic recycling: plastic products factory, packaging industry, plastic recycling station.

- Wood treatment: furniture manufacturing, construction industry, landscaping.

- Metal recycling: automobile dismantling plant, metal products factory, metal recycling station.

- Tire recycling: tire recycling station, rubber products factory.

- Electronic processing: waste computers, mobile phones, TVS, etc.

- Domestic waste treatment: urban waste treatment station, community waste treatment.

- Textile processing: garment factories, textile recycling stations.

- Cable and wire treatment: waste cable, waste wire.

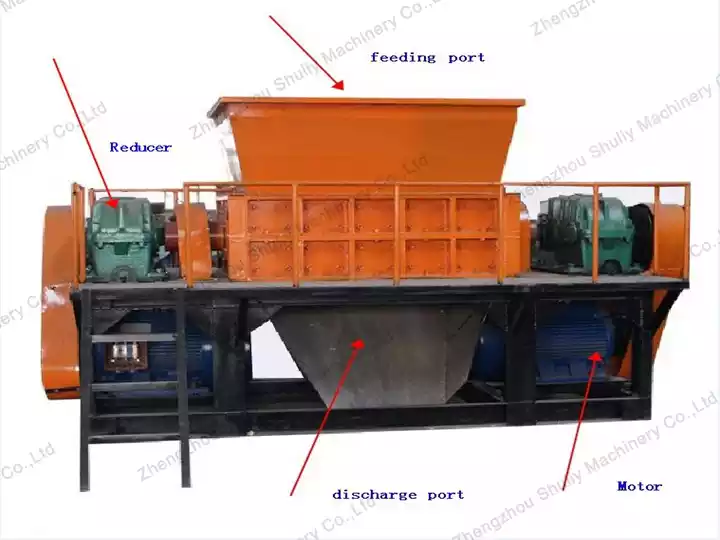

Paper industrial shredder machine main structure

- The feed opening is designed in a funnel shape to allow easy material entry, with its size varying based on the machine’s processing capacity.

- The shredding chamber contains fixed and rotating knives arranged in single-shaft or multi-shaft layouts to enhance cutting efficiency.

- The drive system includes a motor and reducer, where the motor provides power and the reducer adjusts speed and torque for optimal shredding.

- The discharge opening is an open outlet that allows the shredded materials to exit the machine smoothly.

- The control cabinet is equipped with a PLC and touch screen for monitoring and controlling the shredder’s operation.

- Safety devices such as guards, emergency stop buttons, and safety switches help protect the operator and prevent accidents.

Industrial paper shredder machine parameters

| Model | Size(m) | Capacity(t/h) | Number of blades (pcs) | Power(kw) |

| SL-400 | 2.5×1.5×1.9 | 0.5 | 20 | 7.5*2 |

| SL-600 | 3.5×1.5×1.9 | 1 | 25 | 15*2 |

| SL-800 | 3.8×1.5×1.9 | 3 | 40 | 30*2 |

| SL-1000 | 4.3×1.5×1.9 | 3.5 | 33 | 37*2 |

| SL-1200 | 4.5×1.5×1.9 | 5 | 40 | 45*2 |

| SL-1600 | 5.2×1.5×1.9 | 10-20 | 40 | 55*275*2 |

| SL-1800 | 5.5×1.5×1.9 | 15-30 | 36 | 75*290*2 |

| SL-2000 | 5.7×1.5×1.9 | 20-40 | 20 | 90*2110*2 |

If you are interested in learning more about specific equipment, you can contact us at any time. We can also customize the equipment to suit your demands.

Industrial document shredder machine price

There are many factors that affect the price of industrial document shredder. In terms of equipment, it has processing capacity, technological advancement, functional diversity, material structure and so on. In terms of manufacturers, there are technical strength, brand awareness, manufacturing costs, after-sales service and other factors. In the market, there are competition, market demand and so on.

The price of different types of industrial shredder machine on the market varies from about a few hundred dollars to several thousand dollars. You can choose the equipment that is more suitable for you according to the processing capacity, equipment quality, manufacturer strength, and your own budget.

If you want to get the latest quotation of industrial shredder machine, welcome to contact us, and we will contact you within 24 hours.

Welcome to choose Shuliy as your industrial shredder manufacturer

- Shuliy’s industrial shredder offers strong performance, high durability, and excellent cost-effectiveness.

- With over 30 global partnerships since 2011, our machines have received wide praise from international customers.

- We provide comprehensive after-sales service, offering prompt support for technical issues and user inquiries.

Other related equipment with industrial shredder machine

Conclusion

With its powerful shredding capabilities, wide material adaptability, and robust design, the industrial shredder machine is an ideal solution for businesses looking to enhance waste processing efficiency and reduce operational costs.

Contact us today to get a customized solution and competitive quotation—let us help you build a more efficient and sustainable recycling system.