Paper pulper machine, often referred to simply as a pulper, is a piece of industrial equipment used in the paper recycling industry. Its primary function is to break down various types of paper materials into pulp, which is a crucial step in the paper recycling and egg tray making process.

What Are the Benefits of Paper Pulper Machine?

- Energy Savings: Shuliy paper pulping processes can be designed to be energy-efficient, especially high-consistency pulping methods, which can result in lower energy consumption compared to other pulping techniques.

- Customization: Paper pulper machines come in various types and sizes, allowing paper mills to select equipment that suits their specific needs and production requirements.

- Wide Application: Paper pulper machines can handle a wide range of paper materials, including newspapers, cardboard, office paper, and more, making them versatile for various recycling applications.

- Easy to use: The machine is so easy to operate that even people who have no experience in using the machine can be invited to operate it.

Structure of Paper Pulper Machine

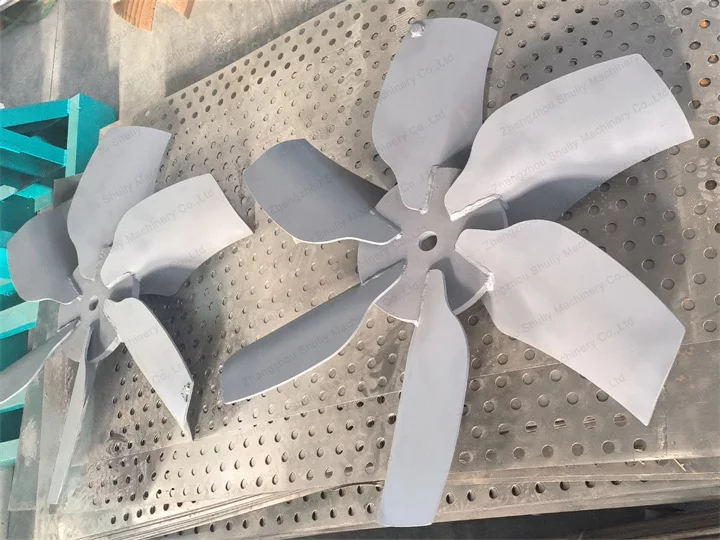

This paper pulper machine mainly includes a rotor, screen plate, working tank body, and transmission mechanism.

Rotor: The rotor is one of the key components in the pulp machine, which plays a key role in breaking down the waste paper into pulp. The rotor rotates and breaks down the waste paper material into fibers through agitation and shearing motion, making it into pulp form.

Screens: Screens are used in the paper pulping process to remove impurities and waste materials from the pulp and to ensure the quality of the final pulp. These panels usually have specific apertures and are designed to filter out unwanted materials from the pulp, such as staples, small pieces of cardboard, etc.

Working trough: The working trough is the part that holds the pulp, rotor, and screen plates. It provides an environment that holds and accommodates the pulp in which the paper pulping process takes place.

Transmission: The transmission is the system used to drive the rotation of the rotor. The drive train transfers energy to the rotor for it to perform the pulping operation.

How Does a Paper Pulper Machine Work?

When the user starts the paper pulp making machine, the impeller inside the machine starts to rotate. The slurry in the tank is then drawn in along the center of the axis and thrown out from the circumference at high speed. This creates an intensely turbulent circulation.

Due to the tearing of the impeller wings and the mutual turbulence of the slurry layers at different velocities a great friction is created. This results in a strong disintegration of the pulp and separation of the fibers in the wet state. At the same time, the fiber bundles rub against each other in the gap between the impeller and the screen plate, increasing the fibrillation effect.

Finally, the slurry flows through the holes in the sieve plate into the slurry pan and is sent to the subsequent processing equipment using a slurry pump.

Technical Specification of Paper Pulp Making Machine

| Model | Capacity(kg/once) | Power(kw) | Size(mm) | Volume(m³) |

| SL-1.0 | 300 | 7.5 | 1400x1200x1400 | 1.2 |

| SL-2.0 | 400 | 11 | 1550x1500x1400 | 2.0 |

| SL-4.5 | 600 | 22 | 2200x2200x2600 | 4.5 |

These are the three hot-selling paper pulper machines, in addition, we also have a variety of paper pulper machines for sale with different outputs.

Types of Paper Pulper Machine

Hydraulic Pulper

Hydraulic pulpers use water and hydraulic forces to break down paper materials into pulp. They are suitable for various paper recycling applications and are often used in the production of pulp for paper and board.

Vertical Paper Pulp Making Machine

Vertical paper pulp making machine is designed for pulping small batches of paper materials. They have a vertical chamber where the paper is agitated and pulped using mechanical means.

Drum Pulper

Drum pulpers consist of a large rotating drum with blades or teeth that shred and break down the paper. They are especially effective for handling high-capacity and high-consistency paper pulping processes.

Continuous Pulper

Continuous pulpers are used for continuous, high-volume pulping operations. They have a continuous feed and discharge system, making them suitable for large-scale paper production facilities.

Price of Paper Pulp Making Machine

The price of a paper pulp making machine can vary significantly based on several factors, including the type and size of the machine, its capacity, features, brand, and where you purchase it from.

- Small Batch Pulpers: Small batch pulpers suitable for laboratory or small-scale applications can range from a few thousand to several thousand dollars.

- Hydraulic Paper Pulp Making Machine: Hydraulic pulpers, commonly used in paper recycling and small to medium-sized paper mills, can cost anywhere from $5,000 to $10,000 or more, depending on capacity and features.

- Drum Pulpers: Drum pulpers, which are often used for high-capacity paper pulping, can range from $50,000 to $200,000 or more, depending on size and features.

- Continuous Pulpers: Continuous pulpers designed for large paper production facilities with high capacity can have prices ranging from $100,000 to several hundred thousand dollars or more.

When considering the purchase of a paper pulp making machine, it’s essential to contact the paper pulp machine manufacturer directly for accurate and up-to-date pricing information.

How to Find a Reliable Paper Pulp Machine Manufacturer?

Finding a reliable paper pulp machine manufacturer involves thorough research, including checking for industry experience, customer reviews, and certifications. Seek recommendations from trusted sources, attend industry trade shows, and engage in direct communication with potential manufacturers to assess their expertise, production capabilities, and commitment to quality and customer support.

Shuliy Machinery is a professional manufacturer of recycling equipment in China. If you are looking for a high-quality paper pulper machine, please contact us through the pop-up window at the bottom right corner.

Shuliy Machinery is a company specializing in recycling machinery manufacturing. After more than 10 years of development, our machines have been exported to more than 30 countries and regions all over the world. If you need a high-quality paper pulper machine, please feel free to contact us.