The PET bottle label remover machine effectively removes labels from plastic bottles, making them easier to recycle. With a capacity of 800–3000 kg/h, this machine is ideal for high-volume recycling operations. It uses physical force—such as rotating brushes and sharp blades—to strip labels from PET bottles without damaging the plastic body.

This process is essential for merchants and recycling facilities that require clean, label-free plastic fragments. As the first step in a PET bottle recycling line, this machine plays a crucial role in improving the efficiency and quality of the entire recycling process.

Benefits of using a plastic bottle label remover machine

- High processing efficiency

- With an output capacity of 800–3000 kg/h, the plastic bottle label remover machine can process a large quantity of bottles in a short time, making it ideal for high-throughput recycling lines.

- Versatile label removal

- This machine can effectively remove various types of labels, including plastic labels, paper labels, and composite materials, ensuring compatibility with different kinds of waste plastic bottles.

- Simple and user-friendly operation

- The machine is designed for easy use and requires no special training, allowing operators to run it with minimal instruction and reducing overall labor costs.

- High label removal accuracy

- With a label removal rate of over 98%, the machine ensures efficient cleaning. The adjustable blades allow it to handle bottles of different sizes while keeping the bottle body intact.

Technical parameters of Shuliy’s PET bottle label remover machine

| Model | SL-600 |

| Capacity | 800-3000kg/h |

| Label removal rate | 98% |

| Power of fans | 3kw |

| Weight | 1500kg |

Shuliy’s PET bottle label remover machine has a powerful processing capacity of 800 to 3000kg/h. The machine is suitable for the production requirements of different pet bottle recycling plants.

The label removal rate is an impressive 98%, demonstrating the effectiveness of its cutting-edge technology in separating labels from plastic bottles.

How does a PET bottle label remover machine work?

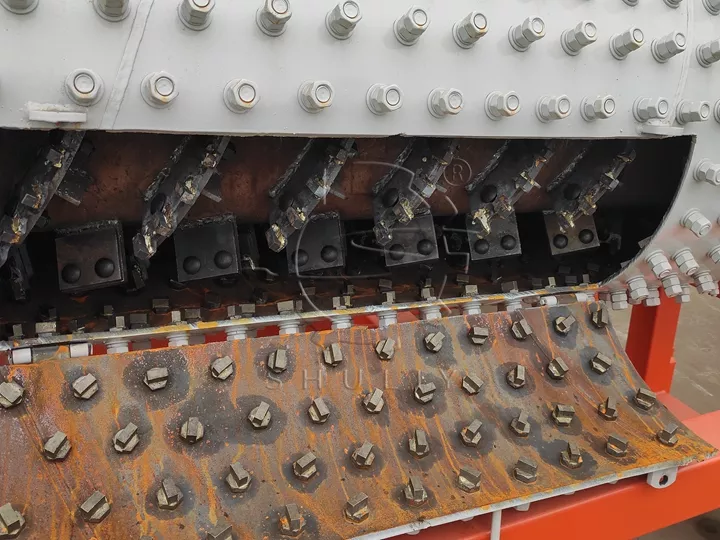

- Label removal by cutting blades

- The machine uses sharp blades to cut off labels from the surface of plastic bottles.

- Rotating cylinder mechanism

- The blades are mounted on a high-speed rotating cylinder that ensures continuous and efficient label removal as bottles move through the system.

- Bottle feeding system

- Bottles are fed into the machine one by one, allowing precise contact with the blades for effective label stripping.

- Air separation system

- After the labels are cut off, a built-in fan blows them away, separating them from the cleaned bottles.

The cutting blades of the PET bottle label remover machine are made of durable alloy steel, which ensures long service life and reliable performance under continuous operation. This robust construction allows the machine to handle large volumes of bottles without frequent blade replacement or maintenance.

The Shuliy PET bottle label remover machine is a very efficient and effective way to remove labels from plastic bottles. It can remove a wide variety of labels, including plastic labels, paper labels, and metal labels. It is also very easy to operate and does not require any special training.

How to use the PET bottle label remover machine correctly?

- Power on and preheat the machine

- Start the machine and allow it to run for a few minutes before loading bottles. This ensures the blades are rotating properly and the fan system is fully functional.

- Load plastic bottles onto the conveyor

- Place the PET bottles evenly on the conveyor belt. Make sure they are aligned correctly to allow smooth feeding into the label removal system.

- Begin the label removal process

- Start the operation. The bottles will automatically pass through the machine, where rotating blades will cut off the labels and the fan will blow them away.

- Shut down and perform maintenance

- After processing is complete, turn off the machine. Conduct routine maintenance by checking the blade condition and cleaning the conveyor and internal parts to ensure continued efficiency.

PET label remover machine applications

- Recycling: removes labels from PET bottles to prepare them for efficient plastic recycling.

- Reuse: enables cleaned bottles to be reused in producing plastic products or construction materials.

- Pre-processing: serves as a necessary step before crushing bottles into flakes for new plastic manufacturing.

- Other uses: can assist in cleaning bottles for creative or alternative applications like art projects.

Different ways to remove labels from plastic bottles

- Mechanical removal: this method uses razor blades or similar physical tools to peel labels off plastic bottles, offering high efficiency but with a risk of damaging the bottles.

- Chemical removal: this approach involves applying chemical solvents to dissolve the adhesive, preserving the bottle integrity but potentially causing environmental pollution.

Conclusion

In summary, the PET Bottle Label Remover Machine is an essential piece of equipment for any plastic recycling line. With its high efficiency, wide label compatibility, and user-friendly operation, it significantly improves the quality of recycled materials and streamlines the pre-processing stage.

Whether you’re running a large recycling plant or starting a new recycling project, this machine is a smart investment to enhance productivity and ensure clean, label-free plastic bottles. Feel free to contact us for more details or to customize the machine according to your specific needs.