PET bottle recycling line has now become a necessary production line for major plastic recycling plants. If you want to engage in the plastic recycling business, then you need to know more about this production line in detail. Next, we will give you a detailed introduction to the various aspects of the plastic bottle recycling line, so as to solve your questions about this plastic recycling line.

Introduction of Pet Bottle Recycling Line

PET bottle recycling line is a set of machinery and equipment used for the recycling of polyethylene terephthalate (PET) plastic bottles. In fact, our pet bottle recycling line can recycle plastic bottles made of a variety of materials, except that pet is the most common.

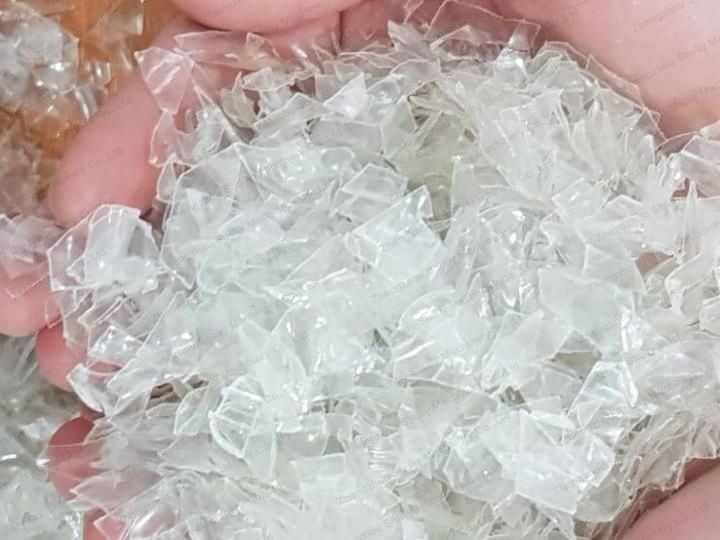

PET is a commonly used material for packaging beverages, food, and other consumer products. PET bottle recycling lines are designed to collect, sort, clean, and process used PET bottles, transforming them into reusable plastic flakes.

Complete the Pet Bottle Recycling Process

The complete PET bottle recycling process includes de-labeling, shredding, high-temperature washing, secondary washing, drying, and storage. Each step is indispensable. Of course, we can also customize the exclusive plastic bottle recycling line according to the specific needs of customers.

Plastic Bottle Recycling Machine in Pet Bottle Recycling Line

Plastic Bottle Conveyor

This plastic bottle recycling machine is used to convey plastic bottles to the plastic de-labeling machine. There are several baffles on the machine, the baffles can prevent the plastic bottles from falling during the conveying process. The steel frame construction ensures the longevity of the machine.

Plastic Bottle De-Labeling Machine

Plastic Bottle De-Labeling Machine is designed to remove labels from pet/plastic bottles. Compared to manual label removal, plastic bottle de-labeling machine is characterized by high productivity and clean label removal. The machine can de-label bottles of different sizes.

Plastic Bottle Crusher Machine

As the name suggests, a plastic bottle crushing machine is used to crush plastic bottles. It crushes PET bottles into plastic flakes of uniform size. The plastic bottle crusher is one of the main machines in this PET bottle recycling line.

Plastic Bottle Flakes Washing Tank

The plastic bottle flake Washing tank has two purposes. The first purpose is to separate PET caps from PET flakes. The second purpose is to clean crushed plastic flakes. There are several moving flaps in the machine. It can push the plastic flakes forward.

Pet Flakes Hot Washing Machine

The Pet flakes hot washing machine washes away contaminants such as oils and beverage liquids from plastic bottle flakes. During the plastic flakes washing process, the operator needs to add detergent to the machine to increase the cleaning effort. As the machine starts, the paddles inside the machine rub against the plastic bottle pieces to clean them.

Plastic Flakes Friction Washing Machine

In order to achieve the purpose of thorough cleaning, we have added another plastic flakes friction washing machine to the PET bottle recycling line. When the plastic flakes enter the machine, the high-speed rotating screw will stir the PET flakes to clean them fully. Under the action of centrifugal force, the machine can clean the surface of plastic PET flakes from sand, soil, and other dirt. Finally, the material is rinsed with clean water.

Pet Flakes Dryer

Plastic Bottle Chip Dryer is the last important machine in the plastic bottle recycling line. The dehydration rate of this machine is up to 97%. The machine is mainly driven by the motor to rotate the spindle at high speed.

At the same time, this allows the plastic bottle chips inside the machine to rotate at high speed as well. The centrifugal force of the machine’s rotation dries the plastic flakes.

Plastic Bottle Chip Storage Boxes

The storage box is used to store dried plastic bottle chips. The machine is made of stainless steel and is characterized by its robustness and durability. There is a small outlet at the bottom of the machine for subsequent packaging.

Feature of Pet Bottle Washing Line

- Comprehensive cleaning process: The pet bottle washing line incorporates various cleaning stages, including de-labeling, crushing, and multiple washing steps, ensuring thorough and efficient cleaning of PET bottles and flakes.

- Customization options: Shuliy’s PET bottle recycling line can be tailored to meet specific production requirements, allowing for flexibility in processing different sizes and types of PET bottles.

- High productivity: The output of this pet bottle washing recycling line ranges from 500-6000kg/h. This allows for the processing of large quantities of PET bottles in a relatively short period of time.

- Advanced washing technology: The use of advanced washing machinery and techniques, such as hot washing and friction washing, ensures the effective removal of impurities and contaminants from PET flakes.

Raw Material that Can Be Used in the Pet Bottle Recycling Line

This production line can process all kinds of plastic bottles such as carbonated beverage bottles, mineral water bottles, soft drink bottles, edible oil bottles, detergent bottles, shampoo bottles, lotion bottles, condiment plastic bottles, sauce bottles, cola bottles, juice bottles and so on. If you are not sure whether your raw materials can be processed by our plastic bottle recycling line, please feel free to contact us.

Pet Bottle Recycling Line Price

The price of a PET bottle recycling line can vary depending on several factors, including the specific components and features of the recycling line, the production capacity, the brand, the quality of materials used in construction, and the technological sophistication of the machinery. Generally, a complete PET bottle recycling line can range in price from several thousand to several hundred thousand dollars or more.

It’s important to consider that the price may also include additional costs such as installation, training, and after-sales support. Additionally, customization options or specific add-ons to the machinery may also affect the overall cost.

To get an accurate and up-to-date price for a PET bottle recycling line, it’s recommended to directly contact Shuliy Recycling Machinery- a plastic bottle recycling line manufacturer. You can provide us with your specific requirements and production needs, and request a detailed quotation.

Which Plastic Bottles Are Recyclable?

Polyethylene Terephthalate (PET or PETE) – Used for water bottles, soft drink bottles, cooking oil bottles, and some food packaging.

High-Density Polyethylene (HDPE) – Used for milk jugs, detergent bottles, oil bottles, toys, and some plastic bags.

Polyvinyl Chloride (PVC) – Used for pipes, window frames, some bottles, and non-food packaging.

Low-Density Polyethylene (LDPE) – Used for squeezable bottles, shopping bags, and some food packaging.

Polypropylene (PP) – Used for some ketchup bottles, yogurt containers, and medicine bottles.

What Can Recycled Plastic Bottles Be Used For?

Plastic bottles recycled through plastic bottle recycling lines can usually be made into the following products:

New plastic bottles: Recycled plastic can be used to manufacture new bottles for beverages, household products, and personal care items.

Clothing and textiles: Some recycled plastics, particularly PET, can be processed into fibers and used to make clothing, jackets, and textiles.

Packaging materials: Recycled plastics can be used to create packaging materials for various consumer products, reducing the need for new plastic in the packaging industry.

Construction materials: Some recycled plastics can be used in the construction industry to produce materials such as plastic lumber, paving materials, and insulation products.

Automotive parts: Recycled plastics can be utilized in the manufacturing of various automotive components, including dashboards, bumpers, and interior parts.

Furniture: Recycled plastics can be used to produce furniture such as chairs, tables, and outdoor benches.