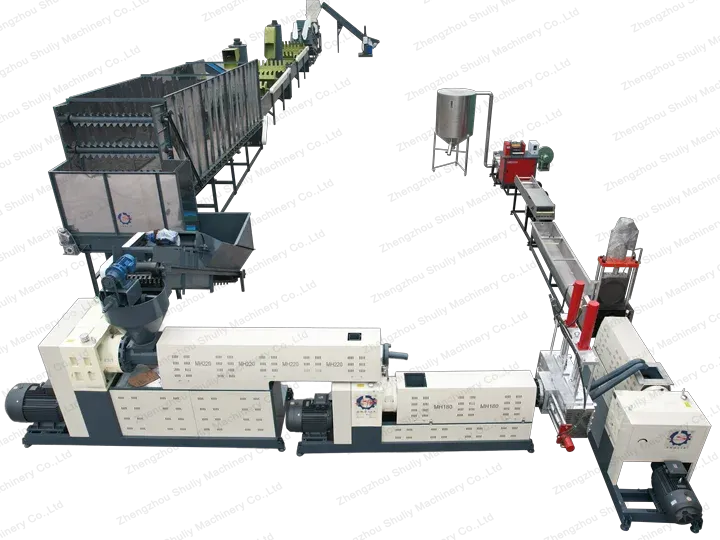

Plastic Film Recycling Line is a specialized industrial system designed for the efficient and effective recycling of plastic films. This plastic washing pelletizing line typically consists of various stages, including crushing, washing, and granulating, to transform used plastic films into reusable plastic pellets. In our company, we also have a plastic bottle recycling line for making clean pet flakes.

Complete Plastic Film Recycling Process

The complete plastic film recycling process includes collection of waste plastic film, shredding, cleaning, dewatering, granulating, cutting, and collection of plastic film pellets. In the following section, we will give you a detailed description of the machines used in each step of the process and how they work.

Plastic Film Recycling Machine in Plastic Film Recycling Line

Plastic Film Conveyor

The plastic film conveyor is a device to transport plastic film into the plastic film shredder. There are several baffles on the machine to prevent the plastic film from falling during transportation. The speed control device can control the conveying speed of the material. We can also customize the length of the plastic film loading machine according to customers’ requirements.

Plastic Film Shredder Machine

A plastic film shredder is a machine that crushes plastic film into plastic film pieces. It is one of the main machines in the plastic film recycling line. Inside the machine, there are multiple blades made of carbon steel material. Under the effect of strong shear force, the large plastic film can be quickly crushed into plastic film pieces.

The output of our plastic film shredder is 600-1200kg/h. You can choose the right machine with the right output according to your needs.

Plastic film washing machine

The pp/pe film washing machine is used to clean the crushed plastic film pieces. This is another important single machine in the plastic film recycling line. There are several rotatable tooth plates inside the machine.

When the machine is started, the plates push the plastic film forward. This moves the plastic film from one end of the plastic film washing machine to the other. This achieves the purpose of cleaning the plastic film.

Plastic Film Dehydrator

As the name suggests, the plastic film dehydrator is used to dry out the water in the cleaned plastic film. Under the action of the centrifugal force of the machine, the water in the plastic film can be effectively removed.

Plastic Film Pelletizing Machine

PE film granulator is one of the most important steps in the whole plastic film recycling line. The plastic film granulator melts the plastic film by heating and squeezing and then pulls the melted plastic film into strips through the die head. The long strips are then cut into plastic pellets of uniform size by a pelletizer.

Cooling Machine

The cooling machine is used to cool the melted plastic film. After being heated and melted by the plastic film granulator, the temperature of the long strip of plastic film will be very high. In order to reduce the temperature of the material, the material needs to be cooled in a cooling tank. This facilitates subsequent cutting and collection.

Plastic Film Pellets Cutting Machine

In order to obtain plastic film granules of uniform size. We need to use a pellets cutting machine to cut long strips of material into plastic pellets of uniform size and shape. A plastic film pellets cutting machine can help you achieve this.

Plastic pellet storage bin and bagging machine

Finally, the plastic pellets can be placed in storage bins for storage and bagging.

Advantages of Our PP/PE Film Recycling Line

- Our PP/PE film recycling line is equipped with highly efficient plastic film recycling equipment. It can effectively process all types of plastic films, including PP, PE, LDPE, HDPE, and PET films.

- The advanced washing and dewatering mechanism ensures thorough cleaning and drying of the plastic film.

- The plastic film particles made are of uniform size and shape.

- The plastic film recycling machine in this plastic pelletizing production line is easy to operate and has low energy consumption.

- High efficiency and large capacity.

- Customizable.

What Plastic Film is Recyclable?

Most types of plastic film are recyclable. The most common types of plastic film that are recyclable include Grocery bags, Produce bags, Bread bags, Newspaper bags, Dry cleaning bags, Zip-top bags, Bubble wrap, Shrink wrap, Plastic wrap, Cereal box liners, Snack bags, Candy wrappers, Six-pack rings, etc.

However, there are some types of plastic film that cannot be recycled, such as plastic bags that contain hazardous materials and Plastic bags that are labeled “non-recyclable”.

Uses of Recycled Plastic Pellets

Recycled plastic pellets can be used as packaging materials, industrial films, building materials, agricultural mulch, toys, electronic products, clothing, textile fabrics, and many other products.

What Are the Costs of Plastic Film Recycling?

The costs of plastic film recycling vary depending on the type of plastic film being recycled, the capabilities of the plastic film recycling line, and the location of the recycling facility. However, in general, plastic film recycling is a cost-effective way to manage plastic film waste. If you want to know the specific price of plastic film recycling line, please feel free to contact us. Our salesman will contact you as soon as possible and give you a detailed quotation.

How to Choose a Plastic Film Recycling Line?

The following factors should be considered when choosing a plastic film recycling line:

- The type of plastic film being recycled: Different types of plastic film require different recycling processes.

- The capabilities of the plastic pelletizing production line: The recycling line should be able to handle the volume of plastic film being recycled.

- The location of the recycling facility: The recycling line should be located in a convenient location for the collection of plastic film.