At Shuliy Recycling Machinery, we have 4 different types of plastic washing machines for sale. They are plastic film washing machines, plastic bottle flakes washing machines, plastic friction washers for pet chips, and pet bottle chips hot washing machines. We will introduce these four types of plastic washing machines to you in detail.

Feature of Shuliy Plastic Washing Machine

- Robust Construction: Our plastic recycling washing machine is built with sturdy materials such as stainless steel for durability and long-term performance.

- Versatile Applications: Suitable for cleaning various types of plastic materials, including plastic film, PET bottles, and other plastic products.

- Advanced Functionality: Equipped with advanced mechanisms and controls for optimal washing efficiency and user convenience.

- Customization Options: Available in various sizes and configurations to accommodate different capacity requirements and operational needs.

- Efficient Cleaning: Different plastic washing machines have different cleaning functions. For example, a PET bottle hot washing tank utilizes hot water and rotating fan blades inside the machine to clean plastic bottle pieces. And plastic friction washing machine uses mechanical friction to remove oil, glue, labels, and other impurities from plastic bottle pieces.

Different Types of Plastic Washing Machines

Plastic Film Washing Machine

Plastic Film washing machine is a machine for cleaning plastic film pieces. The machine is made of stainless steel and iron. It is important to note that the plastic film needs to be pulverized by a plastic film shredder before it can be cleaned. There are many toothed plates inside the machine.

When the pp/pe film washing machine is started, the plates force the plastic film pieces to move forward, transferring the material in the machine from one end of the machine to the other. The purpose of cleaning plastic film fragments can be achieved by pushing and stirring many tooth plates.

Plastic Bottle Flakes Washing Machine

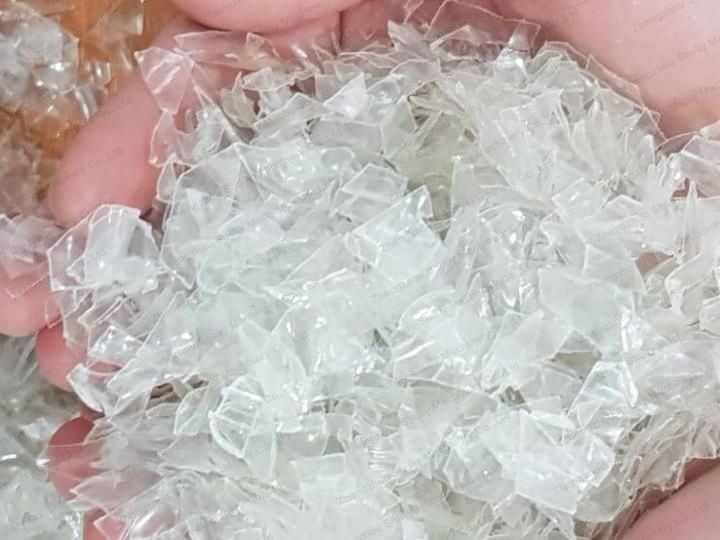

The plastic bottle washing machine can not only clean the crushed plastic bottle flakes, but also separate the plastic bottle flakes and plastic bottle caps. This is an important step in the plastic bottle recycling line. Plastic bottle caps are made of pp or pe. Plastic bottles are made of pets.

This plastic washing machine can make the PET bottle flakes float on the water’s surface by controlling the amount of water and pressure. And the heavier impurities and PP/PE plastic fragments will settle to the bottom of the machine, to realize efficient separation.

Plastic Friction Washer

The plastic bottle flakes friction washer has a high-speed rotating screw inside. This can make the plastic bottle chips and water fully friction and agitation, to clean the sand, oil, leaves, pulp, and other dirt on the surface of the plastic bottle pieces.

PET bottle friction washing machine body consists of the main machine, motor, stand, water inlet, feed inlet, discharge inlet, and so on.

Pet Flakes Hot Washing Machine

The high temperature washing machine is a machine designed to make the plastic bottle flakes cleaner. This plastic washing machine has the functions of temperature control, heat preservation, and agitation. The machine can heat up quickly. Generally, users can add detergent to the machine to clean the plastic bottle flakes.

The size of the plastic bottle hot washing tank can be customized according to the customer’s needs. The agitation speed of the machine is 15 to 120 r/min. The paddle forms are frame type, anchor type, blade type, and turbine type.

Key Features to Consider When Buying a Plastic Washing Machine

- Cleaning Capacity: Evaluate the machine’s capacity to handle the volume of plastic materials you intend to process.

- Material Compatibility: Ensure the plastic washing machine is compatible with the specific types of plastic materials you aim to clean, such as plastic film, PET bottles, or other plastic products.

- Durability and Build Quality: Look for machines made from high-quality materials, such as stainless steel, to ensure longevity and consistent performance.

- Automation and Control: Check for features that allow for easy operation and control, including automated processes and user-friendly interfaces.

- Water Usage: Consider plastic washing machines that optimize water usage without compromising cleaning efficiency, promoting sustainable water management practices.

What Is the Cost of Plastic Scrap Washing Machines?

The cost range for plastic scrap washing machines can vary depending on several factors. Generally, the prices can range from a few thousand to tens of thousands of dollars, depending on the specific type, brand, capacity, and additional features of the machine. Some of the factors that can influence the prices of plastic scrap washing machines include:

- Machine Capacity: plastic washing machines with higher capacities tend to be more expensive due to their ability to handle larger volumes of plastic materials.

- Automation and Advanced Features: Machines equipped with advanced automation, control systems, and additional features for enhancing efficiency and performance are typically priced higher.

- Build and Material Quality: Plastic recycling washing machines are made from high-quality materials, such as stainless steel, durable plastics, and high-performance components. They are generally more expensive than those made from lower-grade materials.

- Customization and Specialization: Custom-built machines tailored to specific requirements or specialized applications come at a premium cost compared to standard models.