Advancements in Foam Granulation Technology

Foam granulation stands at the forefront of innovative particle formation methodologies within various industries, spanning from pharmaceuticals to food production. This groundbreaking process involves the creation of foam by blending liquids or molten substances with gases, culminating in the solidification of foam into granules. This article will delve into the diverse methodologies and machinery employed in foam granulation.

Different Foam Granulation Technologies

Mechanical Granulation: A fundamental approach in foam granulation, employing mechanical forces to form granules from foam. This technique often utilizes foam granulators equipped with mechanisms to solidify foam into desired particle sizes.

Chemical Granulation: This methodology involves chemical reactions aiding in foam solidification, offering precise control over granule characteristics such as size and density.

Physical Granulation: Utilizing physical processes like freezing or cooling to solidify foam into granules, this method ensures the preservation of sensitive substances.

Foam Granulation Machinery

The heart of foam granulation lies in specialized machinery tailored for diverse methods:

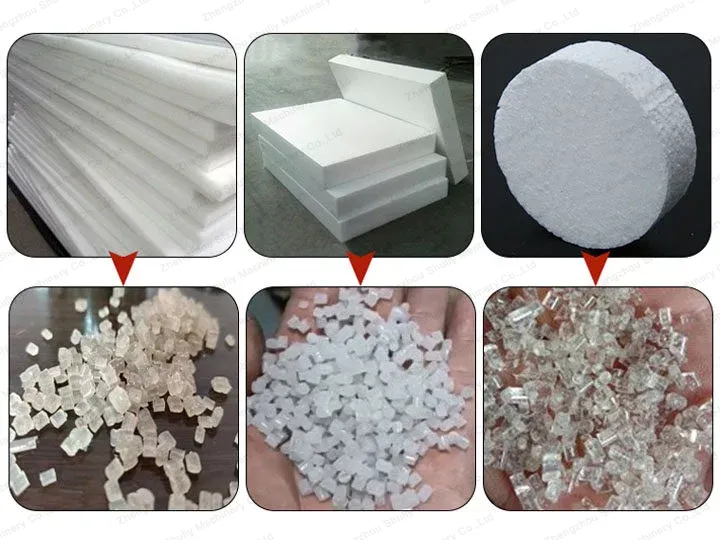

EPS Foam Pellets Machine

These EPS foam pellet machines play a pivotal role in shaping foam into uniform granules. By controlling factors like temperature, pressure, and agitation, foam granulators transform foam into finely tuned particles suitable for various applications.

Fluidized Bed Granulators

Employing fluidization principles, these machines suspend foam particles in an upward-moving gas stream, promoting even granule formation and facilitating drying processes.

Spray-Dry Granulators

Utilizing atomization techniques, these machines convert liquid foam into granules by spraying it into a drying chamber, resulting in rapid solidification and particle formation.

Applications and Advantages

The applications of foam granulation span across industries:

- Pharmaceuticals: Enabling precise control over drug delivery systems and enhancing the solubility of active pharmaceutical ingredients (APIs).

- Food Industry: Utilized in the production of flavor encapsulation, enhancing product stability and shelf life.

- Chemical Manufacturing: Offering a controlled means of producing agrochemicals and specialty chemicals.

Foam granulation stands as a pivotal technology revolutionizing particle formation across various industries. The evolution of methodologies and machinery continues to drive advancements, catering to the intricate needs of diverse applications, ensuring enhanced product quality, efficiency, and innovation.