The Aluminum Plastic Separator is an environmentally friendly recycling machine for the efficient separation of aluminum and plastic composite materials, with a capacity of 200–1200 kg/h and a sorting purity index of ≥99%.

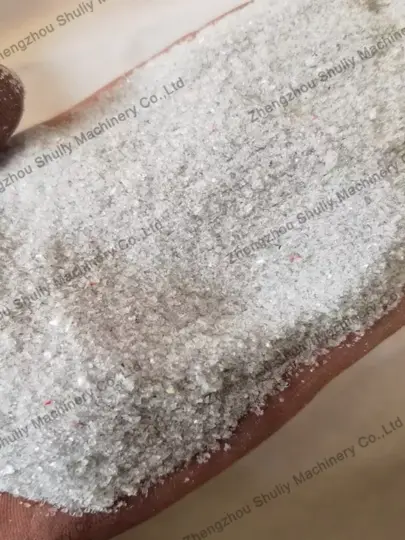

By adopting a physical separation process, this equipment completely separates metallic aluminum from plastics in aluminum–plastic composites, enabling resource recycling and significantly increasing the added value of recovered materials.

It is widely used in recycling plants, electronic waste processing enterprises, battery recycling industries, and environmental protection projects. Featuring excellent separation efficiency, stable operation, and pollution-free performance, it is an ideal solution for aluminum–plastic composite material recycling.

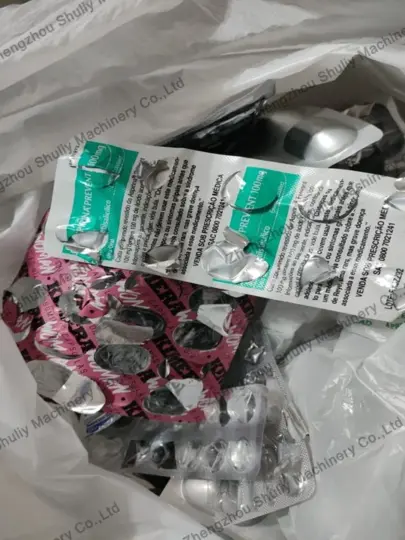

What materials are suitable for the aluminum plastic separation machine?

The aluminum plastic separation machine is suitable for a wide range of aluminum–plastic composite materials, especially those commonly generated in packaging and recycling industries. Typical applicable materials include food aluminum–plastic packaging, pharmaceutical blister packs for tablets and capsules, and aluminum–plastic edge scraps and offcuts from packaging manufacturers.

In addition, the machine can process various types of aluminum–plastic laminated materials, achieving efficient physical separation of aluminum and plastic without chemical treatment, making it an ideal solution for recycling aluminum–plastic waste from food, pharmaceutical, and packaging industries.

Aluminum plastic separating machine working process

- Crusher – Initial crushing of aluminum–plastic panels or other raw materials into smaller pieces.

- Wind Feeder – Uses airflow to transport crushed materials evenly to the next stage.

- Cyclone Feeder – Collects and directs materials for smooth downstream processing.

- Storage Hopper & Electromagnetic Vibrating Feeder – Ensures uniform feeding into the milling and separation system.

- Water-Cooled Mill – Fine grinding of materials while preventing overheating, melting, or discoloration of plastics.

- Rotary Vibration Screening Machine – Screens and separates materials by size for efficient downstream processing.

- Pulse Dust Removal Equipment – Collects dust and purifies the working environment.

- Elevator – Transports materials to the electrostatic separation unit.

- Electrostatic Separation System – Separates aluminum from plastic with high purity.

- PLC Automatic Control Cabinet – Provides intelligent control and monitoring of the entire production line, ensuring smooth, coordinated operation.

Aluminum plastic separator advantages

- Intelligent PLC control system ensures automatic operation, uniform feeding, and smooth coordination of the entire production line.

- Compact and well-organized structure delivers stable performance while reducing operating noise, especially in the crushing section.

- Water-cooling technology for crushing and milling prevents overheating, avoiding plastic melting or discoloration during long-term operation.

- Fully physical separation process combining crushing, grinding, and electrostatic sorting, eliminating chemical agents and meeting environmental standards.

- Integrated pulse dust collection system effectively improves on-site air quality and creates a cleaner working environment.

- High separation accuracy, with aluminum and plastic purity reaching up to 99.9% or higher.

- Flexible customization options allow the system to be tailored to different capacity and production requirements.

Aluminum plastic separation machine parameters

| Model | Power | Sorting Purity index | Collection coefficient | Output | Dimension | Weight |

| SL-300 | 70KW | ≥99% | ≥99.5% | 200-300kg/h | 7500*6000*4200mm | 6500kg |

| SL-600 | 115KW | 500-600kg/h | 9500*7500*4200mm | 7800kg | ||

| SL-800 | 215KW | 700-800kg/h | 11500*8000*4200mm | 12800kg | ||

| SL-1000 | 287.8kw | 1000-1200kg/h | 16x5x9x4.2m | / |

What is the price of the aluminum plastic separator machine?

The price of an aluminum plastic separator machine cannot be defined with a single fixed figure, as it depends on multiple factors—especially the type of material you intend to process.

Different input materials require different equipment configurations, which directly influence the overall cost. For example, if the raw material is simple aluminum–plastic panels, a basic setup including a crusher, mill, elevator, and electrostatic separator may be sufficient.

However, if the material is more complex—such as aluminum–plastic pharmaceutical blister boards—the system typically needs additional equipment like a water-cooled mill and rotary vibrating screen on top of the basic configuration.

Why choose our aluminum plastic separator?

- The machine can directly crush and separate whole aluminum–plastic panels or other boards with a width of up to 180 cm and a thickness of up to 14 mm, as well as various lump materials with diameters below 180 cm, offering very broad material adaptability.

- The entire aluminum–plastic separation process is fully mechanized and automated, requiring only 1–2 operators, effectively reducing labor costs.

- All machine components are easy to install and support multiple assembly configurations, which can be custom-designed according to the customer’s existing site, solving space and layout constraints efficiently.

Supporting equipment of aluminum plastic separator

The Aluminum Plastic Separator can be paired with a Aluminium Briquetting Machine to compress separated aluminum into high-density briquettes, improving storage, transport, and processing efficiency.

Combined, they provide a complete aluminum recovery solution, reduce material loss, and increase recycled value. The separator also works with other metal and plastic processing equipment for flexible, scalable recycling operations.

Conclusion

For businesses looking to efficiently recycle aluminum–plastic composites, our Aluminum Plastic Separator offers a reliable, high-purity, and environmentally friendly solution.

If you are interested in boosting your recycling efficiency and reducing labor costs, contact us today for a detailed quotation and personalized configuration. In addition to aluminum–plastic separation, we also provide a wide range of metal and plastic processing equipment, enabling you to expand your recycling capabilities and meet diverse production needs.