يمكن لآلة تجريد ACP أن تقوم بتسخين لوحة الألومنيوم البلاستيكية المركبة، وإذابة مادة الربط، بحيث يمكن فصل الألومنيوم والبلاستيك بسهولة. آلة تجريد ACP تتجنب التلوث الثانوي للبيئة من خلال طريقة الفصل المادي الجاف. ولها مزايا أكثر من 99% كفاءة الفصل وسهولة التشغيل والاستثمار الصغير. ومع تعزيز الوعي بحماية البيئة ونمو الطلب على إعادة تدوير النفايات وإعادة استخدامها، سيكون لتطبيقها في صناعة إعادة التدوير أيضًا مستقبل أوسع.

مميزات آلة تجريد صفائح ACP

- فصل فعال. من خلال التحكم الدقيق في التسخين، فإن آلة فصل صفائح ACP تجعل الألمنيوم والبلاستيك منفصلين بسرعة، وهذا ما يحققه معدل الفصل 99%.

- قدرة معالجة عالية. يمكن للآلة معالجة 2-6 طن/يوم. ترتبط قدرة المعالجة بحجم اللوحة.

- صديقة للبيئة وموفرة للطاقة. تعتبر طريقة الفصل بالتسخين صديقة للبيئة أكثر من طريقة الفصل الكيميائي التقليدية، مما يمنع توليد النفايات الكيميائية.

- استثمار صغير. يغطي متجرد صفائح ACP مساحة صغيرة ولكنه يتمتع بكفاءة عالية. لذلك يمكن أن يقلل من فقدان المواد في عملية الفصل، ويحقق عودة الاستثمار بسرعة.

- زيادة معدل إعادة التدوير. يمكنها إعادة تدوير وإعادة استخدام الألومنيوم والبلاستيك المنفصلين على التوالي، وتحسين استخدام الموارد وتقليل هدر المواد.

- عملية بسيطة. تتمتع الماكينة بدرجة عالية من الأتمتة، مما يقلل من وقت التشغيل اليدوي ويحسن سلامة التشغيل.

ما هي الصناعات التي يمكن تطبيق آلة فصل ACP عليها؟

صناعة إعادة تدوير الألواح المركبة من الألومنيوم والبلاستيك. يمكن تطبيق آلة فصل الألواح المركبة من الألومنيوم على مصانع إعادة تدوير الألواح المركبة من الألومنيوم وشركات معالجة الموارد المتجددة.

مجال إعادة تدوير مواد التعبئة والتغليف. يمكنها إعادة تدوير مواد التعبئة والتغليف المختلفة من الألومنيوم والبلاستيك، مثل أكياس التعبئة والتغليف المصنوعة من ACP للأدوية والأغذية.

إعادة تدوير النفايات الإلكترونية. تحتوي العديد من النفايات الإلكترونية أيضًا على ألواح مركبة من البلاستيك والألومنيوم، مثل الكابلات القديمة ولوحات الدوائر.

صناعة البناء والديكور. يمكن أيضًا إعادة تدوير وفصل الألواح المركبة من الألومنيوم والبلاستيك الناتجة أثناء عمليات البناء والديكور بواسطة آلة فصل ACP الخردة.

مبدأ العمل لآلة تقشير لوحة الألومنيوم المركبة

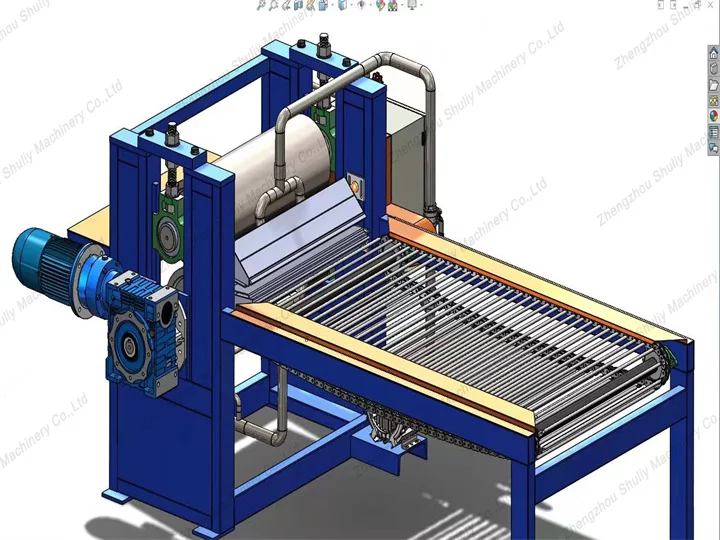

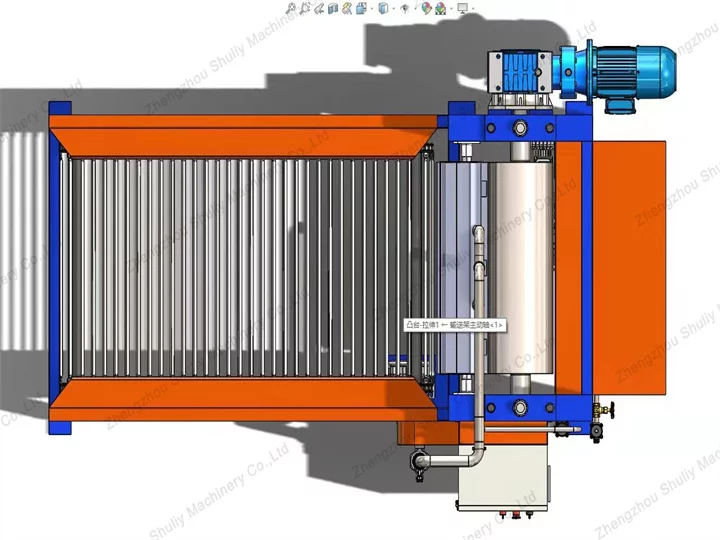

آلة فصل تسخين اللوحة ACP تتكون بشكل رئيسي من جهاز التغذية، نظام التسخين، نظام الفصل، نظام التحكم والهياكل الأخرى.

يتم فصل لوح الألمنيوم والبلاستيك المركب عن طريق التسخين بالنار بشكل رئيسي بسبب المواد المختلفة للوحة الألومنيوم واللوحة الأساسية. معاملات التمدد الحراري مختلفة، ويمكن فصلهما تلقائيًا بعد التمدد الحراري.

عملية فصل لوحة الألومنيوم البلاستيكية المركبة

أولا، التغذية. يتم تغذية لوحة الألومنيوم البلاستيكية المركبة على طول اتجاه التغذية.

ثانيا، الضغط. يتم بثق لوحة الألومنيوم البلاستيكية عن طريق أسطوانة ضغط ذات سطح مرتفع، بحيث يتم تشكيل المنخفضات المواجهة للداخل على جانبي لوحة الألومنيوم البلاستيكية.

ثالثا، التدفئة والفصل. الرش والتسخين المتزامن لجانبي اللوحة المركبة المبثوقة، بحيث يتم فصل الألواح المعدنية على كلا الجانبين تلقائيًا عن اللوحة الأساسية المتوسطة.

متجرد ورقة ACP للبيع

| نموذج | إس إل-600 | الحزام الناقل Bt-1000mm |

| عرض العمل | 600 ملم | منصة تجريد الألومنيوم بمحرك سلسلة والعتاد |

| الحجم (الطول * العرض * الارتفاع) | 1400 مم * 1500 مم * 1100 مم | 1500*1000*1000 مللي متر |

| وزن | 800 كلغ | 200 كلغ |

| الجهد االكهربى | 380 فولت/2.2 كيلو وات، 50 هرتز/3 مراحل (علبة المحرك تكون مخصصة) | |

| سعة | 4t/8h | |

| استهلاك الغاز | 2.5 كجم/ساعة | |

| ملائم | جميع أنواع المواد ACP |

بالإضافة إلى هذا النموذج من آلات تقشير طبقات الألومنيوم المذكورة أعلاه، يمكننا أيضًا تخصيصها وفقًا لاحتياجاتك. فيما يتعلق بمعدات إعادة تدوير المعادن، لدينا مكابس الخردة المعدنية، كسارات المعادن، مقصات المعادن وغيرها متاحة. نرحب بكم في الاتصال بنا للحصول على أحدث عروض الأسعار، والمعدات عالية الجودة، وتخصيص خط الإنتاج!

Shuliy: مورد آلة تقشير ألواح الألومنيوم المركبة

- عالي قوة التكنولوجيا. منذ عام 2011، يصر مهندسونا الفنيون على البحث والتطوير في معدات إعادة تدوير المعادن. نحن نعمل باستمرار على تحسين تقنية الفصل الفعالة وتحسين أداء آلة الفصل ACP.

- تجربة صناعة غنية. مع تجربة إعادة التدوير الغنية، يمكن لشركتنا تقديم حلول أكثر شمولاً للصعوبات التقنية واحتياجات الإنتاج التي يواجهها العملاء في عملية فصل الألواح المركبة من الألومنيوم والبلاستيك.

- خدمة ما بعد البيع. شراء آلة تجريد ACP لديه خدمة ضمان لمدة عام واحد. يمكننا أيضًا توفير التدريب على التشغيل والصيانة والدعم الفني لمساعدة العملاء على ضمان الإنتاج السلس بسرعة.

- ضمان الجودة. لدينا نظام إدارة جودة مثالي لضمان اختبار المعدات بدقة قبل الإنتاج والشحن لضمان استقرار ومتانة المعدات.

الأسئلة المتداولة

هل يمكن استخدام الألومنيوم والبلاستيك الذي تم الحصول عليه بعد الانفصال مرة أخرى؟

نعم. يمكن الاستمرار في إعادة تدوير جزء لوح الألومنيوم كمواد معدنية، ويمكن أيضًا استخدام الطبقة البلاستيكية كمواد خام للمنتجات البلاستيكية الأخرى بعد المعالجة.

ماذا علي أن أفعل إذا كانت درجة الحرارة غير متساوية أثناء الاستخدام؟

قد تؤثر درجة الحرارة غير المتساوية على تأثير الفصل، مما يؤدي إلى تليين غير كامل للطبقة البلاستيكية أو تشوه طبقة الألومنيوم. في هذا الوقت، يمكنك التحقق مما إذا كان جهاز التسخين ونظام التحكم في درجة الحرارة طبيعيين، أو ضبط معلمات درجة الحرارة للتأكد من أن درجة حرارة كل جزء من آلة فصل الألواح ACP موحدة.

كيفية ضمان السلامة أثناء عملية الانفصال؟

لضمان السلامة، آلة تجريد ACP عادةً ما تكون مجهزة بأجهزة استشعار لدرجة الحرارة وأنظمة تحكم أوتوماتيكية لمراقبة وتنظيم درجة حرارة التسخين لتجنب ارتفاع درجة الحرارة. بالإضافة إلى ذلك، فهي مجهزة بأجهزة أمان متعددة مثل زر التوقف في حالات الطوارئ والحماية من الحرارة الزائدة لمنع وقوع الحوادث.