Egg tray production line is a device used to produce egg trays. The egg carton production line uses waste paper to make egg trays, which is a very environmentally friendly product. The paper egg tray production line mainly includes pulping part, egg tray forming part, drying part, and packaging part. Shuliy’s paper egg tray production line has been sold to Cameroon, Uzbekistan, Zambia, Nigeria, and other places, and has been welcomed.

The Complete Egg Tray Production Process

Raw Material Preparation

The production process begins with the preparation of raw materials, which are usually recycled paper products such as waste paper, cardboard, or old newspapers. These materials are collected, sorted, and pulped to create a slurry.

Pulping

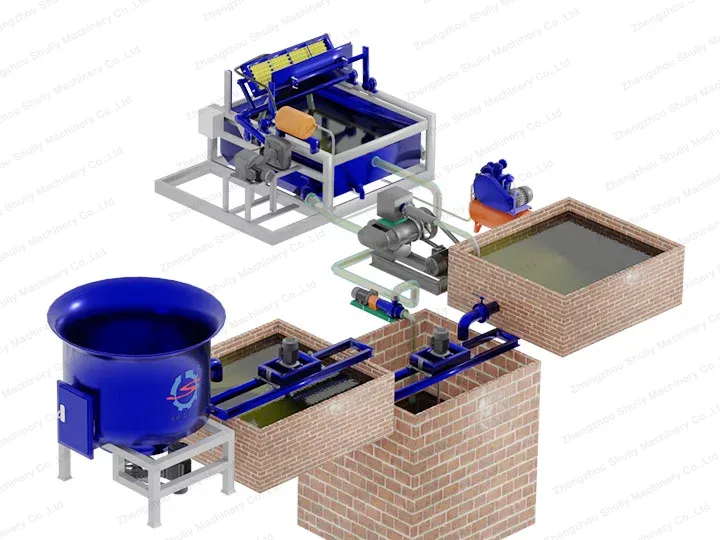

The pulping machine is the first step in the egg tray production line. It is used to break down the raw materials into a pulp mixture by adding water and chemicals. This process helps in breaking down the fibers in the paper and creating a consistent slurry.

Molding

Once the pulp is prepared, it is fed into the molding machine. The paper pulp molding machine consists of molds that have the shape of egg trays. The pulp is poured into these molds, and a vacuum or hydraulic press is used to remove excess water and shape the pulp into the desired tray shape.

Drying

After molding, the wet egg trays need to be dried to remove excess moisture. This is typically done in an egg tray drying machine, where hot air is circulated to evaporate the water. The trays are often dried to a specific moisture content to ensure they are sturdy and durable.

Packaging

The finished egg trays are packaged in bulk for shipping and distribution. They can be bundled together in stacks or placed in boxes for easy handling and transportation.

Main Equipment of the Egg Tray Production Line

Pulping Equipment

Paper Pulper: This waste paper pulp making machine is used to break down and mix the raw materials (such as waste paper) with water to create a pulp mixture.

Molding Equipment

Egg Carton Machine: The paper pulp molding machine contains molds or dies in the shape of egg trays. It’s responsible for forming the pulp into tray shapes using vacuum or hydraulic pressure.

Drying Equipment

Drying Chamber or Conveyor System: After molding, the wet trays are conveyed to a drying chamber or through a conveyor system where hot air is circulated to remove moisture and dry the trays.

Stacking and Packaging Equipment

Egg Tray Packaging Machine: Depending on the production scale, various packaging machines may be employed to bundle the trays for shipping and distribution.

Optional Equipment

Hot Pressing Machine: Egg tray production line can use hot pressing equipment to further strengthen and shape the egg trays.

Pulp Beating Machine: This machine is used to refine and homogenize the pulp mixture for better quality trays.

Technical Data of Egg Tray Production Line

| Model | Capacity | Power | Voltage | Paper consumption | Water consumption | Size(molding machine) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 80kg/h | 160kg/h | 2600*2200*1900mm |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 120kg/h | 240kg/h | 2800*2200*1900mm |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 200kg/h | 400kg/h | 2900*1800*1800mm |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 240kg/h | 480kg/h | 3250*1800*1800mm |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 320kg/h | 640kg/h | 3250*2300*2500mm |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 400kg/h | 800kg/h | 3700*2300*2500mm |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 480kg/h | 960kg/h | 3200*2300*2500mm |

What Is the Cost of Egg Tray Manufacturing Plant

The cost of setting up an egg tray manufacturing plant can vary widely depending on several factors, including the scale of production, location, equipment choices, labor costs, and the availability of raw materials. Below are some approximate cost ranges for different scales of egg tray manufacturing plants:

Small-scale Egg Carton Manufacturing Plant: Small-scale egg tray production plants with manual or semi-automatic equipment may cost between $10,000 to $50,000 USD. These plants are suitable for producing a few hundred to a few thousand egg trays per hour.

Medium-scale Egg Tray Production Plant: Medium-sized plants with semi-automatic or automated equipment can cost between $50,000 to $200,000 USD. These plants can produce several thousand to tens of thousands of egg trays per hour.

Large-scale Egg Tray Manufacturing Plant: Large-scale egg tray production line with fully automated equipment can cost upwards of $200,000 USD and can go into the millions of dollars. These plants are capable of producing tens of thousands to hundreds of thousands of egg trays per hour.

How to Become the Best Egg Tray Manufacturer?

Becoming the best egg tray manufacturer requires a combination of factors, including a commitment to quality, efficiency, sustainability, and customer satisfaction.

Thorough Market Research

Understand the demand for egg trays in your target market.

Analyze your competitors to identify opportunities for differentiation.

Stay updated on industry trends and customer preferences.

Invest in Quality Equipment

Acquire modern and efficient egg tray production machinery.

Ensure regular maintenance and calibration of equipment for consistent quality.

Source High-Quality Raw Materials

Secure a reliable supply of high-quality recycled paper or other raw materials.

Test and inspect raw materials for consistency and purity.

Focus on Product Design and Innovation

Design appealing and functional egg tray packaging.

Innovate in terms of design, material, and manufacturing processes.

Quality Control and Assurance

Implement stringent quality control measures at every stage of production.

Continuously monitor and improve product quality.

Skilled Workforce

Hire and train skilled workers for equipment operation and maintenance.

Promote a culture of quality and continuous improvement among employees.

What Products Can the Egg Tray Production Line Produce?

Our egg tray production line can make many different finished products, such as fruit trays, shoe trays, quail egg trays, ostrich egg trays, nursery trays, wine bottle trays, coffee cup trays and so on. You only need to change different molds for different products.

Advantages of the Egg Tray Production Line

- Wide application: Egg tray production lines can be adapted to manufacture a wide range of tray and packaging products, not just limited to egg trays. This versatility allows businesses to diversify their product offerings.

- Wide range of outputs to choose from: At Shuliy Recycling Machinery, we have a wide range of egg carton production lines with outputs ranging from 1,000-7,000pcs/h for egg tray manufacturers to choose from.

- Easy Maintenance: The egg tray equipment used in these egg carton production lines is designed for easy maintenance and repair, minimizing downtime.

- Sustainable Packaging: The resulting egg trays are biodegradable and eco-friendly, reducing environmental impact and waste generation.

Why Choose Shuliy Recycling Machinery?

- Quality Products: Shuliy is known for producing high-quality recycling machinery that is built to last. Our recycling equipment is designed for durability and reliable performance, which can lead to long-term cost savings.

- Wide Range of Products: Shuliy offers a wide range of recycling machinery, including equipment for processing materials like paper, plastic, metal, and more. This variety allows you to find the right equipment for your specific recycling needs.

- Customization: We often offer customization options, allowing you to tailor the equipment to your specific requirements and applications.

- Experience and Expertise: Shuliy Recycling Machinery has years of experience in the recycling industry and a team of experts who can provide guidance and support to help you choose the right equipment and optimize your recycling processes.

- Competitive Pricing: Shuliy Recycling Machinery often provides competitive pricing for its equipment, making it a cost-effective choice for businesses.