EPS foam pelletizing machine is a machine used to recycle polystyrene (EPS). In the EPS pelletizing line, this machine is the most important one. This equipment is designed to make EPS foam scrap into smaller, more manageable EPS pellets. The granulation process of EPS foam includes three steps: melting, drawing, and pelletizing. EPS pellet mills help to reduce the size of the foam scrap and make it easier to transport for recycling.

Features of EPS Granulator

- It can reduce the volume of EPS foam by more than 90%, saving transportation and disposal costs.

- Melting and granulating integrated design: The EPS granulator has an integrated design, which can melt EPS foam and granulate it directly, simplifying the whole foam granulation process.

- The EPS pellets are consistent in size and uniform in shape.

- The foam granulator can improve the recycling rate of EPS foam and reduce environmental pollution.

- Easy to operate: our foam granulators are designed to be simple and easy for operators to operate and maintain.

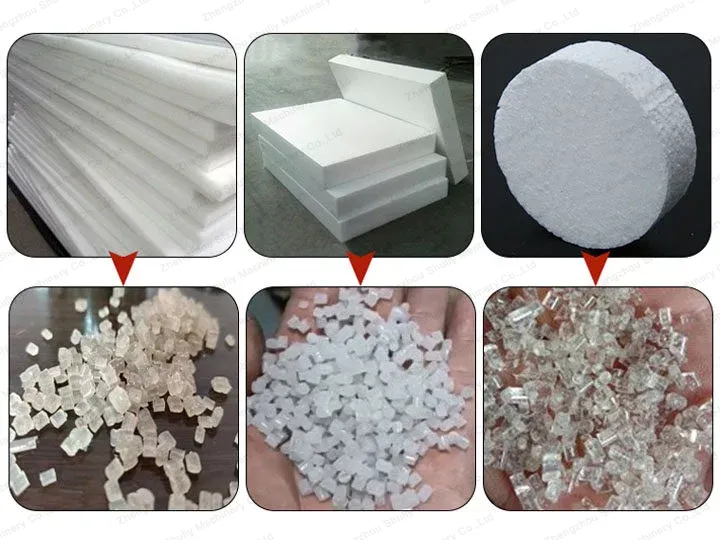

Which Raw Materials Can Be Put in the EPS Foam Pelletizing Machine?

There are a lot of EPS foam products available for recycling in daily life. Common materials include electronics, boxes for glassware, insulation boards, thermal boards, EPS flooring, disposable lunch boxes, cushioning foam pads, and fresh food containers.

How Does EPS Foam Pelletizing Machine Work?

Below is the complete EPS foam pelletizing process. For the first time, the staff needs to feed the EPS foam scrap into the heating chamber of the EPS foam pelletizing machine. By the way, the EPS foam needs to be crushed by a foam shredder machine before it can enter the machine.

In the heating chamber, the EPS foam will be heated to a molten state. The heating chamber is usually heated by electricity or gas. Then, the melted EPS foam will enter the auxiliary machine of the EPS foam pelletizing machine and be pulled into strips.

The strips are then cooled in a cooling tank. Finally, the pellets cutting machine cuts the long strips of material into uniform-sized EPS pellets.

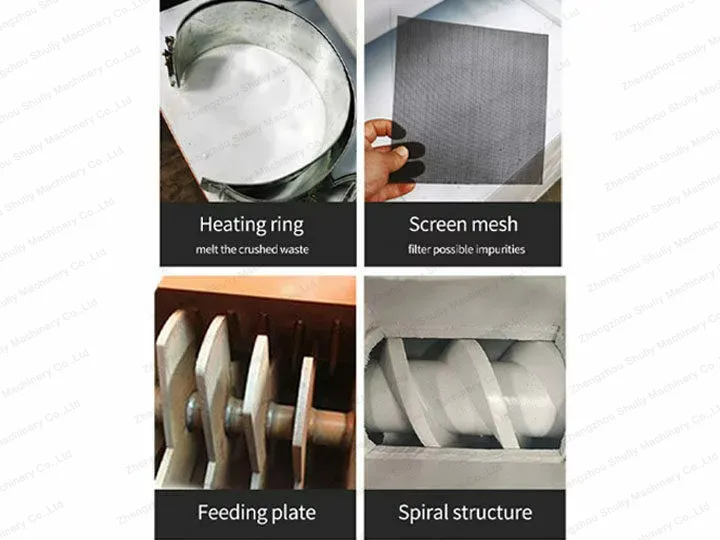

Detailed Display of the Machine

Technical Parameters of EPS Foam Pelletizer

- 220 type (double reducer): its processing capacity is 150-175 kg per hour, and the main motor power is 15 kW.

- 270 type (double reducer): its processing capacity of 200-225 kg per hour, the main motor power of 18.5 kilowatts.

- Model 220 (single reducer): its processing capacity of 150-175 kg per hour, and the main motor power of 15 kilowatts.

- 270 type (single reducer): its processing capacity of 200-225 kg per hour, the main motor power of 18.5 kilowatts.

- 320 type (double reducer): its processing capacity of 275-300 kg per hour, the main motor power of 18.5 kilowatts.

- Type 350 (double-speed reducer): its processing capacity is 325-375 kilograms per hour, and the main motor power is 22 kilowatts.

As can be seen from the above table, customers can choose the main motor power of the EPS foam pelletizing machine according to their needs. At the same time, customers can also choose a double reducer or single reducer according to their needs.

Applications for EPS Granules

EPS granules made from the Shuliy EPS foam pelletizing machine can make the following products.

- Filling materials: EPS granules can be used as filling materials, such as filling toys, furniture, and packaging. EPS granules are lightweight and flexible, providing good cushioning and protection.

- Insulation: EPS pellets can be used as an insulation material, for example, to fill walls, roofs, and pipes. EPS pellets have good insulation properties and can help save energy.

- Building materials: EPS pellets can be used as a building material, e.g. for manufacturing EPS panels, EPS bricks, and EPS flooring.

- EPS pellets are lightweight and durable and can be used in a variety of construction applications.

- Other applications: EPS pellets can also be used in other applications, such as making mats, planting substrates and aquaculture materials.