With increasing environmental awareness and the gradual improvement of policies and regulations, the future of industrial foam machines is bright. These innovative machines provide effective solutions for recycling polystyrene materials, reducing resource waste and promoting sustainable development. If you are now looking for relevant EPS recycle machines to carry out recycling projects, you can get more valuable information according to this article.

What is an EPS Recycle Machine?

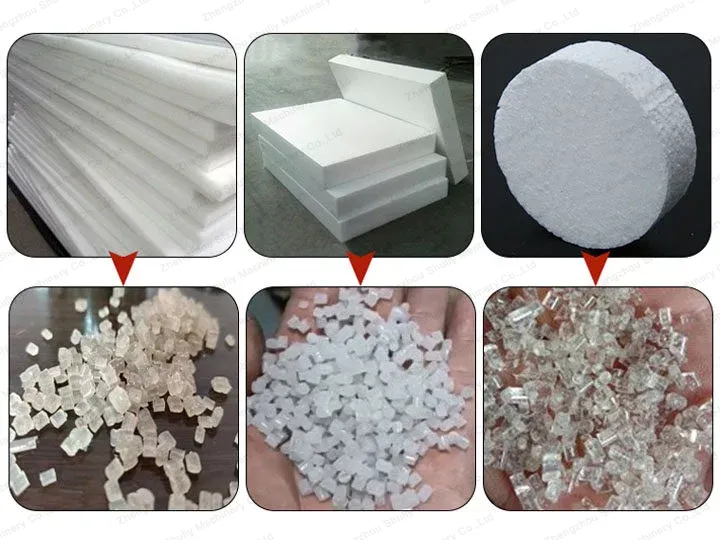

Expanded polystyrene is a lightweight foam material used in a wide range of applications such as packaging, construction, and cold chain transportation. Due to its excellent insulation and cushioning properties, polystyrene is often used as protective packaging in the transportation of goods. However, polystyrene recycling still faces challenges due to its large size and non-biodegradability.

As a result, styrofoam recycling machines have emerged to make pellets by recycling and reprocessing waste expanded polystyrene for further utilization.

Multifaceted Benefits of Using EPS Recycling Machines

- Economic efficiency. Enterprises can gain economic benefits by recycling expanded polystyrene, while reducing raw material procurement costs, realizing a win-win situation.

- Resource reuse. The EPS recycle machines effectively convert waste polystyrene materials into reusable pellets, reducing dependence on new materials and helping to conserve resources.

- Environmental efficiency. Through recycling and reprocessing, it reduces the pollution of waste foam to the environment and lowers the environmental burden caused by landfills and incineration.

- Image enhancement. Enterprises that actively participate in EPS recycling can enhance their environmental image and market competitiveness.

Applications and Industries Benefiting from EPS Recycling Machines

- Packaging industries. They extensively utilize expanded polystyrene materials for insulation and protection during shipping. Consequently, these sectors heavily rely on EPS foam recycling machines to manage and reprocess the discarded foam packaging materials efficiently.

- Electronic manufacturing companies. These frequently use styrofoam for cushioning delicate components in their products. This industry segment also benefits from EPS recycling machines to handle and recycle expanded polystyrene used in packaging electronic devices.

- Construction industries. Styrofoam recycling equipment assists construction businesses in managing construction waste, specifically styrofoam materials, contributing to a more eco-friendly building process.

- Retail chains and supermarkets that deal with perishable goods. These businesses can utilize EPS recycle machines to responsibly manage the polystyrene waste generated from their packaging needs.

Key Features and Functionality of Styrofoam Recycling Machines

Foam recycling machines mainly include foam crushing machine, styrofoam compactor, foam pelletizing machine and foam melting machine.

Shuliy’s horizontal foam shredder machine can support multiple models to choose from, adapting to the needs of each scale. It runs stably for a long time while quickly crushing large waste expanded polystyrene into small pieces.

The EPS foam compactor uses advanced cold compression technology that efficiently compresses waste expanded polystyrene into dense blocks without heat, reducing the volume by up to 40 times. This facilitates the storage and transportation of styrofoam at a later stage.

The EPS granulator is a machine that converts waste expanded polystyrene into plastic pellets. Shuliy’s foam granulator machine adopts an integrated design, which can melt waste expanded polystyrene and pelletize it directly, simplifying the foam pelletizing process. The finished pellets are uniform in size and meet international quality standards.

Foam melting machine can be crushed and has melting function. It melts the expanded polystyrene by rapid heating and significantly reduces the volume of expanded polystyrene. Simple operation and efficient processing.

Choosing the Right EPS Recycle Machine for Your Needs

Selecting the ideal styrofoam recycling machine involves considering factors such as processing capacity, space requirements, and additional functionalities like shredding capabilities or automation.

You are welcome to send us your relevant information, such as raw materials, processing capacity, budget, etc. at any time. We can provide customized services according to your individual needs.

What Are the Cost of Foam Recycling Machines?

When contemplating the cost considerations for polystyrene recycling machines, several factors influence the pricing spectrum of these innovative devices.

The type and capacity of the foam recycling equipment play the critical role in determining its cost. Larger-capacity machines equipped with advanced compression mechanisms or additional shredding functionalities might entail a higher initial investment.

Moreover, the brand reputation and technological advancements integrated into the EPS recycle machine can influence pricing. Machines from established manufacturers offering automation features, energy-efficient operations, or multi-stage recycling processes might have a higher upfront cost but can lead to long-term savings and enhanced efficiency in foam recycle operations.

Consideration of operational costs is crucial. Assessing factors like energy consumption, maintenance needs, and raw material expenses for the recycling process is imperative in understanding the overall cost of ownership.

If you would like to learn more about the market outlook and the benefits of your project, you can contact us. We can advise you on the development of your EPS recycle project, design options, line configuration and other services that can efficiently help you solve your problems.

Comparison Between Different EPS Recycle Technologies

Comparing different polystyrene recycling technologies provides insights into their respective advantages, limitations, and suitability for diverse applications.

Mechanical Recycling

This method involves shredding, melting, and reforming foam into new products. This kind of styrofoam recycle machine is cost-effective and energy-efficient. but it might degrade the material’s quality due to multiple melting processes.

Chemical Recycling

Chemical processes break down polystyrene into its components, which can be reused to create new materials. While it can maintain material quality, it often requires more energy and might involve complex processes.

Pyrolysis

The method of styrofoam recycle involves heating polystyrene in the absence of oxygen to break it down into oil, gas, and char. It’s efficient in converting foam into useful products but might require high temperatures and careful control to prevent emissions.

Biological Recycling

Using microorganisms to break down expanded polystyrene into simpler compounds is an emerging method. While eco-friendly, it’s in its infancy and might need refinement for large-scale use.