Foam Compactor Machine for Foam Recycling

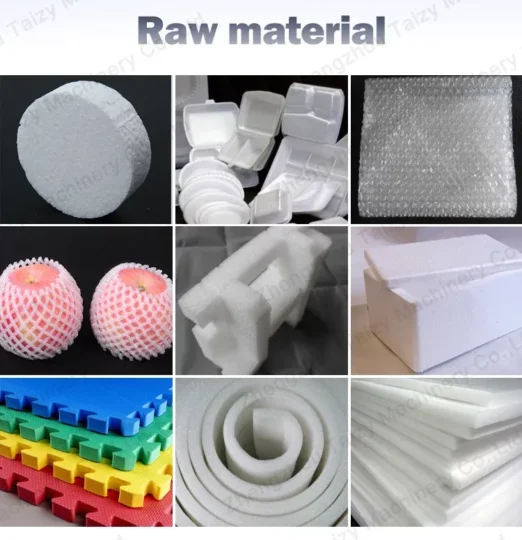

The foam compactor machine is a specialized piece of equipment designed to compress and densify foam waste, such as expanded polystyrene (EPS) foam. By reducing the volume of the foam, these machines facilitate easier storage, transportation, and recycling.

Working Principle of a Foam Compactor Machine

The working principle of a foam compactor machine is relatively simple yet highly effective. The machine consists of a compression chamber, where the foam waste is fed into. Once the chamber is filled, a powerful pneumatic press applies pressure to the foam, compressing it to a fraction of its original volume.

The compressed foam blocks are then ejected from the machine, ready for further handling or recycling. This process not only reduces the volume of the waste but also improves its density, making it more suitable for recycling processes.

Crushing Machine in the Foam Densifier Machine

Foam crushing machines also play a very important role in foam densifier machines. Because, before the foam is compressed, the EPS foam needs to be crushed first. The large foam boards can not enter into the compression chamber of the foam densifier machine.

A foam crusher machine can quickly pulverize large pieces of foam into smaller pieces. Shuliy recycling machine has an efficient foam crushing machine attached to the foam densifier machine.

Key Parameters of a Foam Compactor Machine

When considering a foam compactor machine, several key parameters should be taken into account:

Compression Ratio

This refers to the ratio between the original volume of the foam and its compressed volume. A higher compression ratio indicates a more efficient machine.

Throughput

The amount of foam waste that the machine can process in a given time frame, is typically measured in tons per hour or cubic meters per hour.

Power Source

Foam compactor machines can be powered by electricity, hydraulics, or pneumatics. The choice depends on the specific application and available resources.

Size and Portability

The dimensions and weight of the machine determine its portability and suitability for different locations. Mobile foam compactors are especially useful for on-site recycling operations.

Durability and Maintenance

A reliable machine with low maintenance requirements ensures maximum uptime and cost efficiency.

The Importance of Foam Recycling

Foam recycling is crucial for several reasons. Firstly, it reduces the amount of foam waste ending up in landfills, thus reducing the environmental impact of this non-biodegradable material.

Secondly, recycled foam can be used to create new products, reducing the demand for virgin materials and conserving natural resources. Finally, foam recycling creates economic opportunities for businesses and communities involved in the recycling industry.

Applications of Foam Compactor Machines

EPS styrofoam compactors are used in a wide range of applications. You can see it in garbage recycling centers, foam manufacturing plants, municipal waste management centers, plastic recycling plants, and many other places.

Foam compactor machines are a vital tool in the foam recycling process. Their ability to compress and densify foam waste makes them an efficient solution for reducing waste and promoting sustainability. With the right machine and proper operation, foam recycling can become a viable and profitable business opportunity for many organizations.