Hanger production line refers to a manufacturing setup specifically designed for producing coat/wire hangers. You can make hangers from materials like plastic, metal, wood, composite materials, bamboo, etc. Our hanger production line makes hangers from materials like metal.

Common Types of Shuliy Hanger Production Lines

In Shuliy recycling machinery, there are two main types of hanger production lines: the wire hanger machine and the PVC coated hanger making machine. These lines utilize different materials and processes to manufacture different types of hangers:

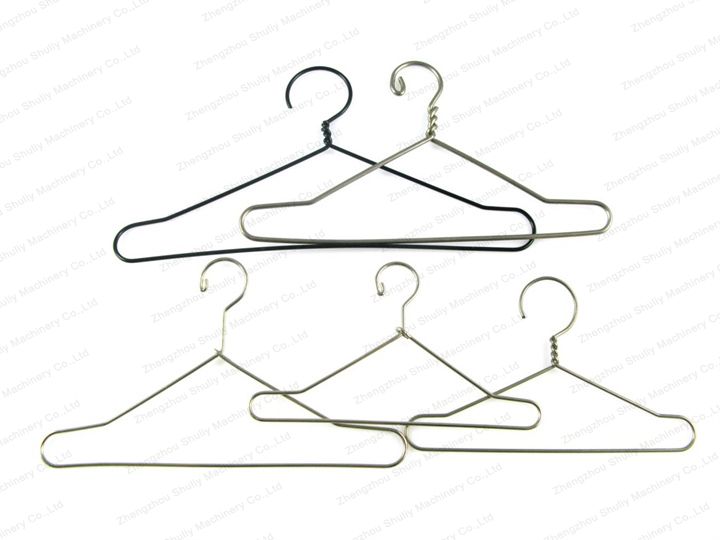

Wire Hanger Production Line

- Raw Materials: galvanized iron wire, steel wire, and stainless steel wire. The maximum processing diameter of these materials is 2.5mm.

- Wire Hanger Production Process. This involves wire placement on the payout shaft, followed by the wire being pulled into the wire hanger machine. The machine then compresses the wire, ensuring it doesn’t twist during the hanger production process. Finally, the metal wire is cut and folded into the shape of the hanger.

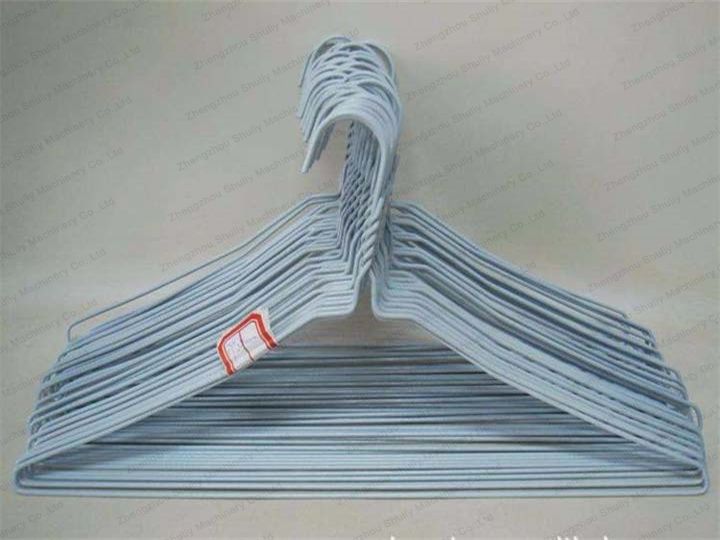

PVC Coated Hanger Production Line

- Raw Materials: steel wire and PVC coating material

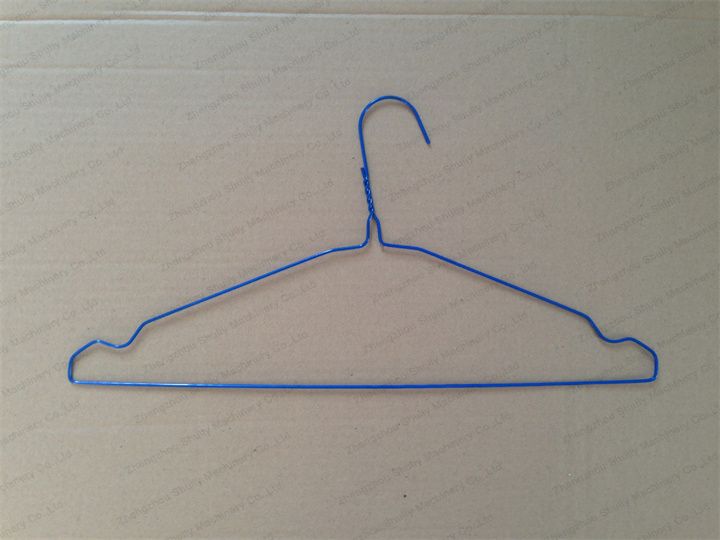

- Production Process: Includes a series of steps such as spraying plastic powder evenly onto the hanger surface using a plastic spray gun and then sending the hangers to a drying room for baking and coloring to fix the plastic particles onto the hanger surface.

These two types of production lines cater to the different requirements of wire and pvc coated hanger manufacturing, showcasing the diversity in the hanger production industry.

What is the Hanger manufacturing process?

The hanger manufacturing process typically involves several key steps, although the specific details may vary depending on the type of hanger being produced.

Material Preparation

Prepare the raw materials, including galvanized iron wire, steel wire, or stainless steel wire.

Wire cutting

When the wire is put to the specified length by the payoff machine, the cutting device will automatically cut the wire.

Shaping

Use a hanger making machine to shape the wires into the desired hanger form.

Spraying plastic powder

Use a plastic spray gun to evenly apply plastic powder onto the hanger surface.

Drying and coloring

Place the hangers in a drying room for baking and coloring, ensuring the plastic particles are firmly attached to the hanger surface.

Quality Control

Conduct thorough quality checks to ensure that the hangers meet the required standards.

Packaging

Pack the finished hangers in suitable packaging for distribution and storage.

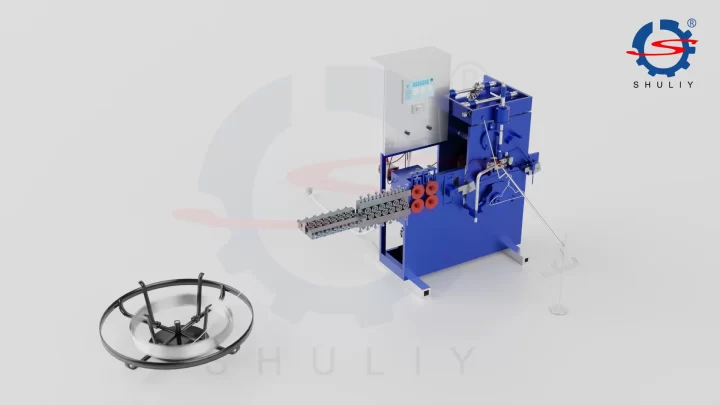

Equipment Involved in the Hanger Production Line

Payoff Machine: Used for handling wire payout, storage, and retraction. It consists of a motor and storage rack for managing wire materials.

Cloth Hanger Machine: Utilized for shaping and forming the wires into the desired hanger structure. It includes mechanisms for wire compression, cutting, and folding.

Plastic Spray Gun: Employed for even application of plastic powder onto the hanger surface during the production of plastic hangers.

Plastic Powder Recovery Chamber: Used for the collection and recycling of any excess plastic powder during the spraying process.

Drying Room: Utilized for the drying and coloring process, ensuring the plastic particles are firmly attached to the hanger surface.

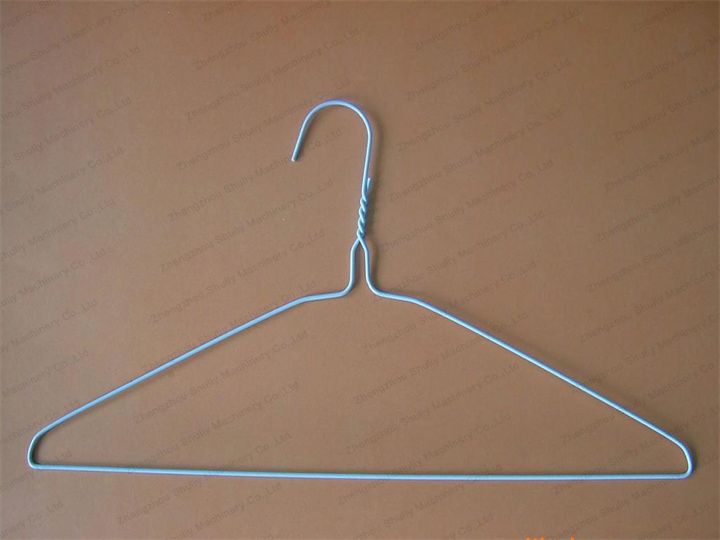

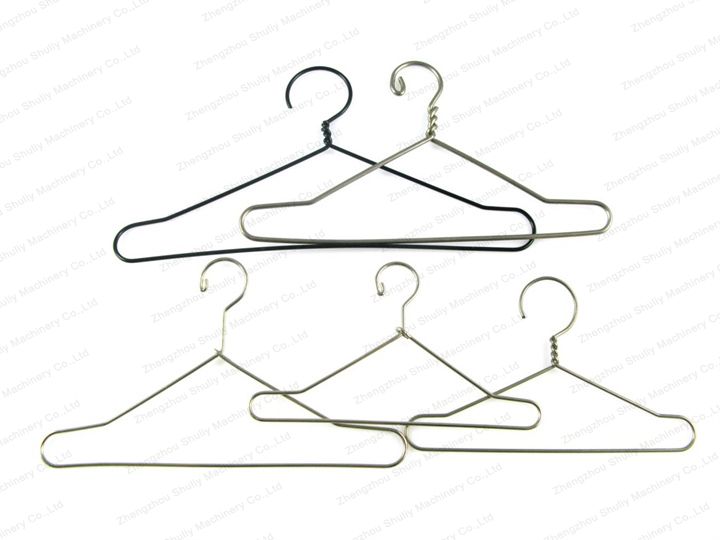

Finished hanger display

What Is the Cost of Establishing a Hanger Production Line?

The cost of establishing a hanger production line can vary significantly depending on various factors such as the scale of the operation, the types of hangers being manufactured, the level of automation, and the specific machinery and equipment required.

Costs may also differ based on the region or country where the production line is being set up due to variations in labor costs, raw material availability, and regulatory requirements.

key cost components to consider when establishing a hanger production line include hanger machinery and equipment costs, raw material costs, labor costs, facility costs, regulatory compliance costs, and maintenance and operating costs.

Common Challenges Faced in Hanger Production Line Manufacturing

Several common challenges can arise during hanger production line manufacturing. These challenges can impact efficiency, product quality, and overall profitability.

- Material Supply and Quality: Ensuring a consistent supply of high-quality materials, such as steel wire or plastic, can be challenging and can affect the quality and durability of the hangers.

- Equipment Maintenance: Regular maintenance of hanger making machine is crucial to prevent breakdowns and ensure consistent production. Downtime for repairs can disrupt the production schedule and lead to delays.

- Quality Control: Ensuring consistent quality across all produced hangers is essential. Quality control processes need to be implemented at various stages to identify and rectify any defects or inconsistencies.

- Skilled Labor: Operating and maintaining the specialized equipment used in hanger production requires skilled labor.

- Cost Management: Managing production costs, including raw materials, labor, and equipment maintenance, while remaining competitive in the market, can be a significant challenge.