Is EPS Recyclable?

EPS is widely used in packaging, insulation, and various consumer products. Its excellent insulating properties and shock-absorbent characteristics make it a popular choice in multiple industries. However, the environmental impact of polystyrene has raised significant concerns due to its non-biodegradable nature.

The article provides an in-depth discussion on the recyclability of expanded polystyrene, its application areas, granulation and recycling process, and market prospect analysis.

Understanding EPS

EPS is a lightweight foam material, which contributes to its lightweight and insulating properties. Commonly used in food containers, packaging materials, and construction applications, styrofoam can last for hundreds of years in landfills if not properly managed. Its longevity poses a significant environmental threat, as it can break down into microplastics that contaminate ecosystems and harm wildlife.

Can You Recycle Styrofoam?

Yes, EPS is recyclable. But the recycling process can be more complex than that of other materials such as paper or metals.

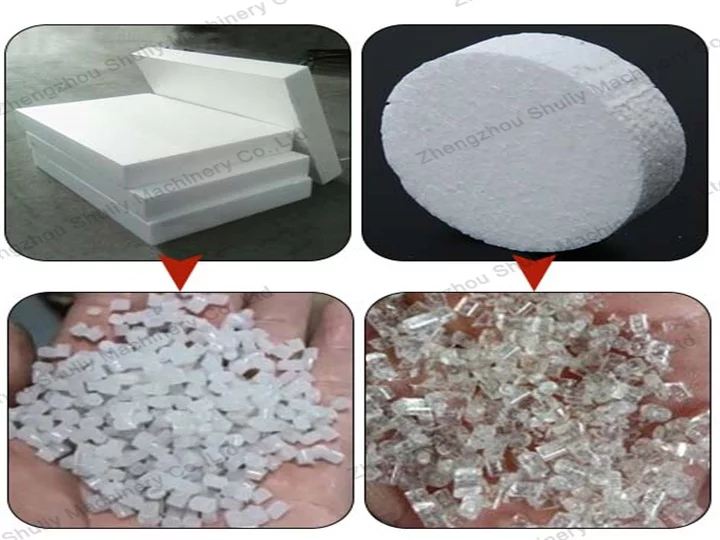

What Products Recycled Styrofoam Can Be Made?

- New EPS products. Recycled foam can be reprocessed to create new foam products, which helps reduce the demand for virgin materials.

- Industrial applications. The recycled material can be used in various industrial applications, including insulation panels and construction materials.

- Plastic lumber. Some recycling facilities convert foam into plastic lumber, which can be used for outdoor furniture, decking, and landscaping products.

Foam Recycling Granulation Process

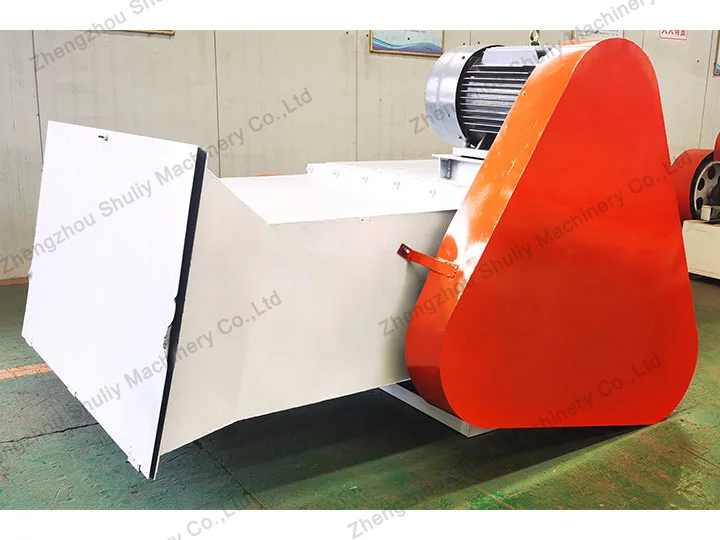

Shredding

Foam is crushed into small pieces or flakes by means of a foam shredder machine. This reduction in size makes EPS easier to handle and process in subsequent steps.

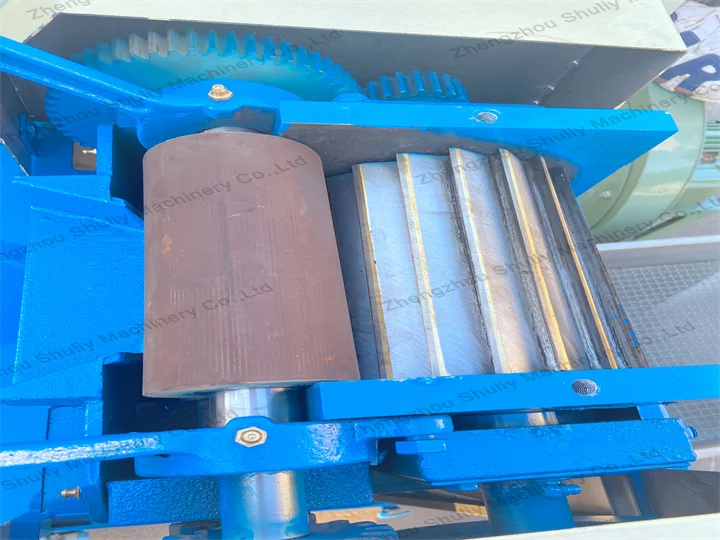

Pelletizing

Foam granulator needs to melt foam flakes through a heating system and extrude them through a mold into new shapes.

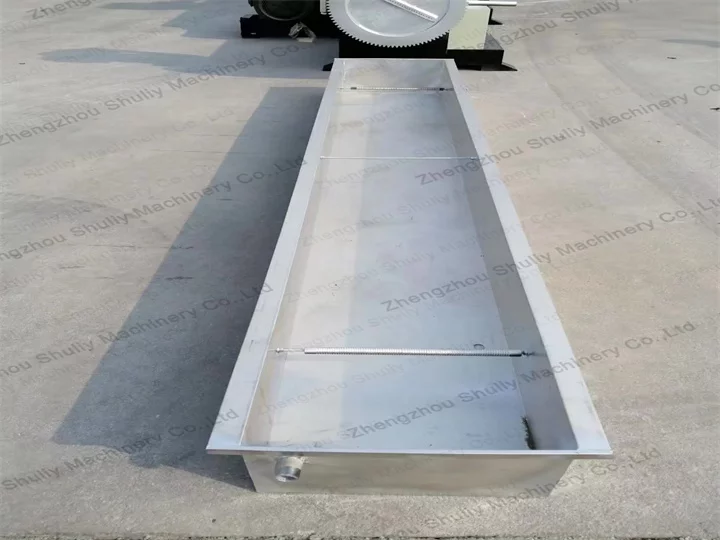

Cooling

The pellets are cooled by means of a cooling tank or an air-cooling unit. This helps with subsequent cutting pellets.

Cutting Pellets

Long strips of cooled plastic are cut into uniformly sized pellets by a pellets cutting machine. At this point, the recycled foam pellets can be used to make new products, completing the recycling cycle.

Packaging and Storage

Pack qualified EPS pellets by weight. And store them in a dry and ventilated place for reuse.

Analysis of Foam Recycling Development Prospects

Policy Support

Many countries and regions are implementing stricter environmental regulations to reduce the generation of plastic waste. The policy push will promote the research and development and application of styrofoam recycling technology, and the government may provide financial support and incentives to encourage enterprises to participate in recycling.

Technological Innovation

As technology advances, polystyrene recycling technology is evolving. The emergence of new and efficient recycling equipment and processes can improve recycling efficiency and reduce treatment costs. For example, improved cleaning and dehydration technologies will make the recycling process more efficient and enhance the quality of recycled foam.

Increased Market Demand

Demand for sustainable materials is rising, with businesses and consumers increasingly favoring products that use recycled materials. Recycled foam can be used to make packaging materials, building insulation and other products, so the increase in market demand will drive the growth of polystyrene recycling industry.

Circular Economy Concept

With the popularization of the concept of circular economy, styrofoam recycling is regarded as an important part of resource reuse. By converting waste EPS into new products, the demand for raw materials can be reduced and the environmental impact can be reduced, thus realizing a win-win situation for both economy and ecology.

Increased Consumer Awareness

Public concern over plastic pollution is growing and consumer demand for environmentally friendly products is rising. The trend prompts more companies to explore the use of recycled materials, which in turn promotes the development of the polystyrene recycling industry.

In Conclusion

In conclusion, expanded polystyrene is recyclable. In addition to that, with the influence of various aspects such as policy support from various countries, technological innovation, market demand growth and public awareness, polystyrene recycling has a bright future. Through further research and investment, styrofoam recycling will become an important way to achieve environmental goals.

If you are now considering a related polystyrene recycling project, please feel free to contact us. As a professional and reliable plastics recycling supplier, we can provide you with market analysis, production line configuration and technical support.