Metal shredder machine mainly reduces the volume of various metal wastes through efficient shredding, which is convenient for packing and processing, recycling and reuse. Because of its high efficient shredding capacity, energy saving and environmental protection, and a variety of models to choose from, metal shredder machine is widely favored by the UK, Belgium, Australia, South Africa, Spain, Malaysia, Pakistan and other countries.

What Are the Types of Scrap Metal Shredder?

Scrap metal shredders are categorized into two main types: single-shaft metal shredders and double-shaft metal shredders. These two types of machines have different capabilities and applications for processing different types and sizes of metal scrap.

Single-Shaft Scrap Metal Shredder

Working Principle: single shaft metal shredder machine has one main rotating shaft, usually fitted with sharp blades. Metal materials are fed into the machine and then degraded into smaller pieces through a process of cutting and shredding by the rotating blades.

Application: small metal shredders are usually used for small scrap processing jobs and light scrap breakdown. Examples include scrap cable, cans, aluminum scrap, circuit boards and some metal impurities.

Dual-Shaft Scrap Metal Shredder

Working principle: the two shaft scrap metal shredder machine has two rotating shafts, each equipped with sharp blades. Metal materials are fed into the machine, where the two rotating shafts work in tandem to degrade it into smaller pieces through a more powerful cutting, tearing, and crushing process.

Application: heavy metal shredder machines are suitable for large scale scrap processing jobs and heavy duty scrap breakdown. Examples include automobile shells, aluminum alloys, scrap metal parts, scrap machinery and equipment, scrap electrical appliances and other industrial and commercial metal scrap.

Advantages of the Metal Shredder Machine

- Wide application: Shuliy’s metal shredder machine has a strong crushing capacity, not only can it crush light materials such as plastic film and waste cartons, but can also crush hard materials such as wood and car shells.

- Structural stability: the main body of the industrial metal shredder is made of high-quality steel plate processed and welded as a whole. After stress relief treatment, it ensures that the machine can remain stable even under long-time load.

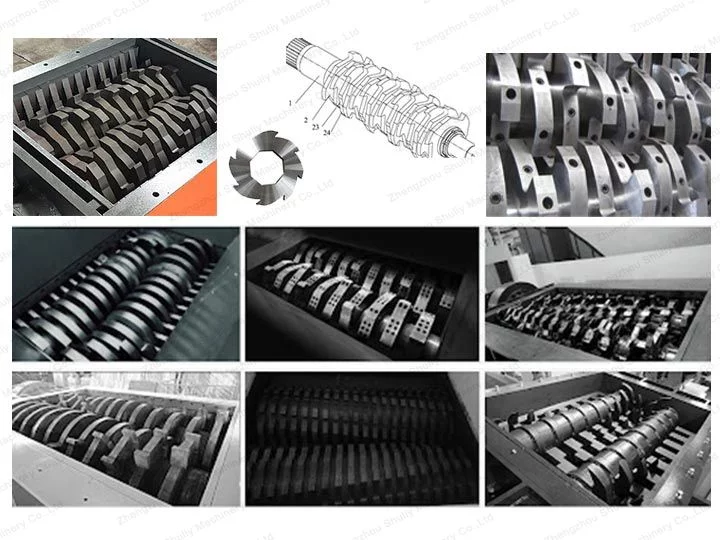

- High-quality blades: the movable blades of the metal shredder machine are made of specialized special alloy tool steel. The knives undergo multiple processes including forging, precision machining, multiple heat treatments, and cryogenic freezing heat treatments to ensure superior cutting performance and long life of the blades.

- Convenient maintenance: the bearing housing of the metal recycling shredder adopts the assembling and disassembling installation method. This type of installation allows users to quickly remove the moving knife, fixed knife, bearings, and other components. In addition, the unique sealing structure effectively isolates metal chips and grease, reducing pollution and damage to the equipment.

- Blade thickness and quantity can be customized: blades are available in 15mm, 20mm, 40mm, 50mm, 75mm, 100mm, and other thickness options for customers to choose from. Also, the thickness of the blades can be customized according to the needs of different materials. In addition, the number of knife jaws can be adjusted and replaced as needed to accommodate different types of waste and materials to be processed.

Different Models of Double Shaft Scrap Metal Shredder for Sale

| Model | Blade material | Number of cutter teeth (pcs) | Number of blades (pcs) | Size(mm) | Wight(t) | Power(kw) |

| SL-400 | 9CrSi | 12 | 20 | 2.5×1.5×1.9 | 1 | 11 |

| SL-600 | 9CrSi | 15 | 25 | 3.5×1.5×1.9 | 3 | 15×2 |

| SL-800 | 9CrSi | 18 | 40 | 3.8×1.5×1.9 | 4 | 18.5×2 |

| SL-1000 | 9CrSi | 18 | 33 | 4.3×1.5×1.9 | 6 | 30×2 |

| SL-1200 | 9CrSi | 15 | 40 | 4.5×1.5×1.9 | 7 | 37×2 |

| SL-1600 | 9CrSi | 15 | 40 | 5.2×1.5×1.9 | 12 | 45×2 |

| SL-1800 | 9CrSi | 15 | 36 | 5.5×1.5×1.9 | 16 | 55×2 |

| SL-2000 | 9CrSi | 15 | 20 | 5.7×1.5×1.9 | 22 | 75×2 |

Above is a wide range of two shaft metal shredder for sale at Shuliy Recycling Machinery. Different machines have different power, size and capacity, so you can choose according to your needs.

In addition, we also have other metal recycling machinery for sale, such as metal baling machines and metal chip briquetting machines. If you want to get equipment details, price or customized services, please contact us anytime.

Key Parts of the Metal Shredder Machine

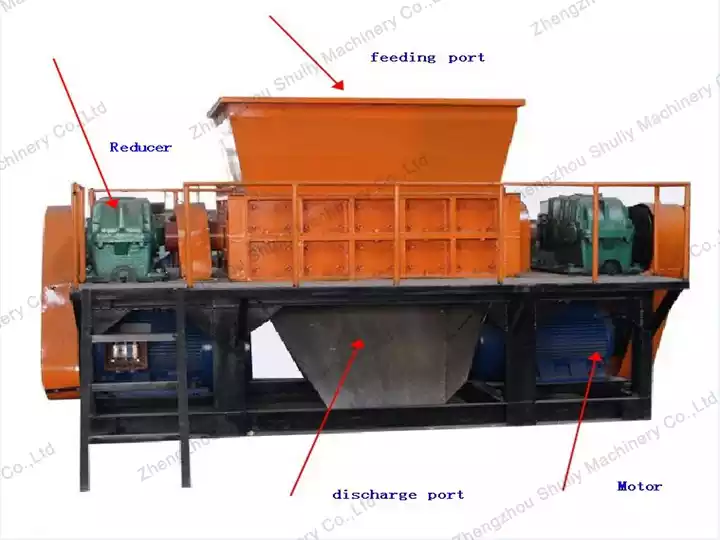

Industrial metal shredder is mainly composed of a blade spindle, fixed knife, carrying box, box support, feeding system, power system, and electrical control system.

The overall structure of scrap metal shredder machine is designed to be compact and easy to operate and manage. And with durability, efficiency and safety in mind, it efficiently pulverizes all kinds of scrap metal materials.

Working Process of the Metal Shredder Machine

Feeding

Staff will feed the scrap metal to be shredded into the shredding chamber through the feeding port. There are fixed knives and rotating blades at the core of the shredding chamber. These blades are made of special alloy tool steel with sharp edges.

Shredding

The high torque motor drives the rotary knives to rotate at high speeds and work with the fixed knives to shred the metal material. The scrap metal material is continuously cut and shredded, gradually turning into smaller pieces.

Screening

The shredded metal particles are screened through a screen to ensure that the size meets the requirements.

Discharge

Qualified metal particles are discharged through the discharge port and enter the next process.

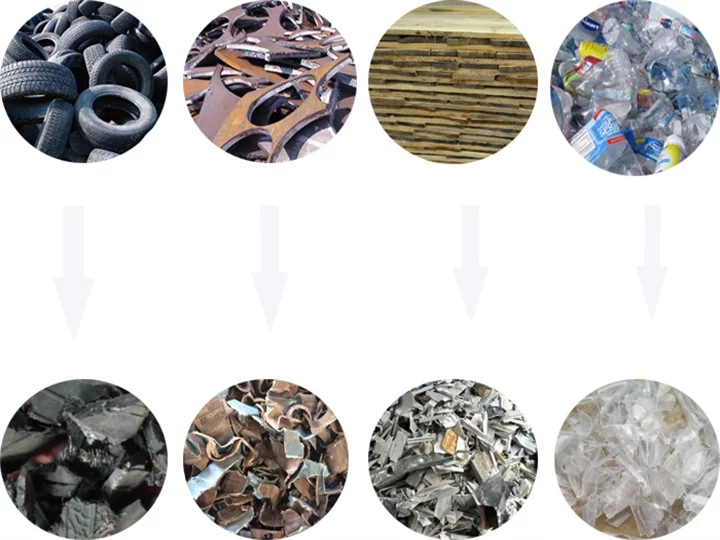

Application of Metal Shredder Machine

- Scrap metal: metal scraps such as car shells, aluminum alloy, scrap cast aluminum parts, engine shells, lead, and steel plates with thicknesses below 15 mm.

- Waste home appliances and furniture: TV sets, washing machines, refrigerator shells, mattresses, sofas, tables, chairs and benches, and other waste home appliances and furniture.

- Pipes and tubes: large pipes, fittings, PE pipes, and so on.

- Waste tires: all kinds of car and truck tires and other waste tires.

- Various hollow containers: plastic beverage cans, plastic drums, iron drums, packing boxes, packing barrels, etc.

- Waste pallets: wooden pallets, plastic pallets, forklift pallets.

- Garbage: kitchen garbage, domestic garbage, animal carcasses, RDF derivatives (combustible garbage fuel), medical garbage, biological orange rods, garden garbage, and other kinds of garbage.

- Glue head material and paper mill strand: materials such as glue head material and paper mill discarded strand.

How to Maintain the Scrap Metal Shredder Machine?

Regular Cleaning

Make sure the surface of the industrial metal shredder is kept clean to avoid the accumulation of dust and impurities. And regularly clean the blades and cutting mechanism to ensure that they remain sharp.

Lubrication

Regularly check the lubrication parts of the scrap metal shredder machine, such as bearings and chains, to ensure that they remain fully lubricated.

Tighten Bolts

Regularly check and tighten all bolts, nuts, and connectors to ensure the structural stability and safety of the machine.

Check Electrical Parts

Regularly check the electrical system, including motors, cables, and control panels to ensure their proper operation.

Regular Maintenance

Perform routine maintenance on the scrap metal shredder regularly, including checking the main components of the machine and blade wear.