The Plastic Film Pelletizing Machine is a vital component in the plastic recycling industry, designed to transform post-consumer or post-industrial plastic films into reusable pellets. This machine efficiently processes a wide range of plastic materials, including PP, LDPE, and woven bags, through a series of steps such as melting, extrusion, cooling, and cutting.

With its high – performance design and cost – effective operation, it can handle capacities from 3000kg to 7000kg per 24 hours, making it a popular choice in countries like Kenya and Nigeria. The machine’s key components work together seamlessly to produce high – quality pellets that serve as valuable raw materials for manufacturing new plastic products.

How does a plastic film pelletizing machine work?

Many people want to know the plastic film granulation process. The working principle of a plastic film pelletizer is simple. The machine melts the plastic film at a high temperature, forces it through a mold, and then uses a pellet cutter machine to cut it into small plastic pellets.

- Turn on the plastic granules making machine.

- Observe the operation of the granules machine, and put it into use after there is no abnormal sound or vibration.

- Preheat the recycling machine to melt the plastic. Note that too high temperature will turn melted plastic black, while too low temperature prevents plastic from melting.

- Put the crushed material into the feeding port of the plastic granulator machine, and add a forced feeder for plastic film material to prevent the recycling machines from not feeding.

- The material melts in the squeezing chamber and is pushed out continuously along with the squeezing screw.

- The material from the main engine will enter the auxiliary pelletizer again for secondary melting and extrusion.

- The material from the outlet can be put into the cooling tank for cooling and cut into small granules by a pellet cutter machine.

Plastic film granulator design

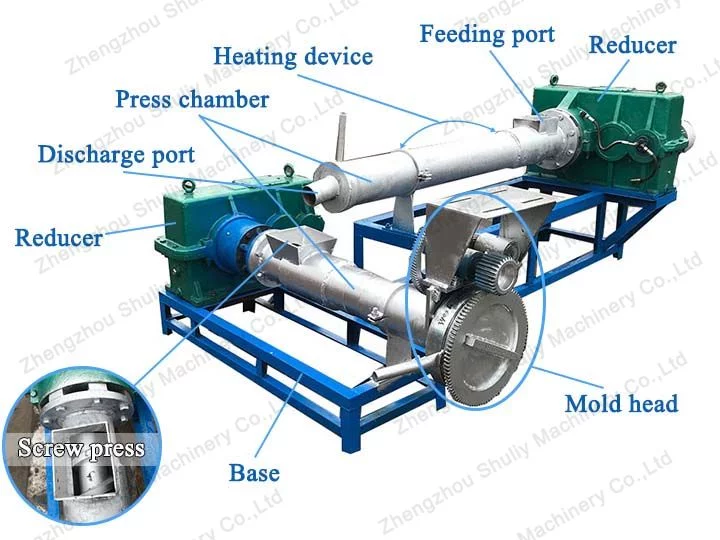

A plastic film granulator is mainly composed of a feed inlet, screw, heating device, extrusion chamber, discharge die head, motor, reducer, and other structures.

The body of the plastic granulator is made of alloy steel material, which is characterized by high heat resistance, high wear resistance, and corrosion resistance.

The screw inside the machine is the device used to push the material forward. The screws are also made of corrosion-resistant and high-strength alloy steel.

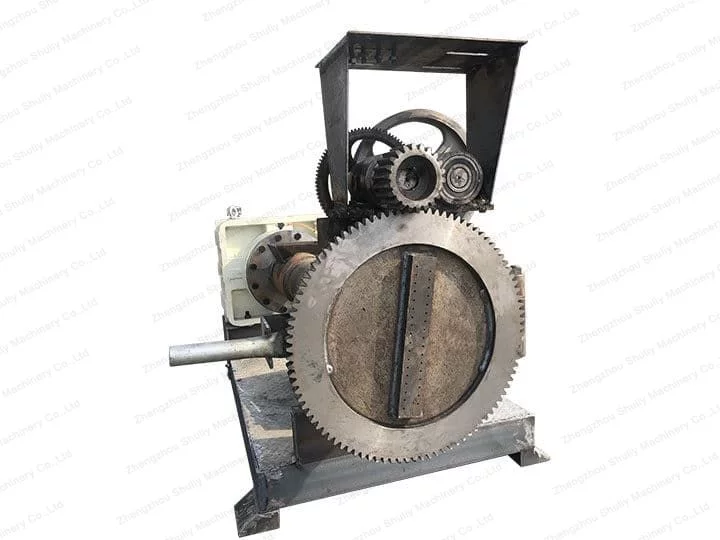

At Shuliy Recycling Machinery, we have three types of discharge die heads such as electric gear die heads, hydraulic die heads, and automatic slag filters.

The machine head is fitted with a grinder alignment device to correct the concentricity of the discharge opening and the die head.

The machine is also equipped with a cooling device to eliminate excess heat generated by the rotating friction of the screw. This prevents excessive temperatures that can cause some unwanted problems.

Plastic film pelletizing machine specifications

| Model | Capacity(t/d) | Main motor(kw) | Screw diameter(mm) | Main shaft speed(min) |

| Sl-125 | 3 | 22+1.5kw | 125 | 50-70 |

| Sl-150 | 5 | 30+1.5kw | 150 | 40-60 |

| Sl-180 | 7 | 45kw | 180 | 40-50 |

The Shuliy plastic film pelletizing machine can produce up to 7t/h. This can meet the production requirements of most plastic film recycling plants. If you have other requirements in terms of throughput, please contact us.

What are the benefits of using a PE film granulator?

- Wide material compatibility

- Suitable for PE, PP, PET, and other film types—ideal for diverse recycling needs.

- Effective waste reduction

- Converts film waste into pellets, reducing landfill and incineration impact.

- Recyclable output for new products

- Produces reusable pellets, lowering reliance on virgin plastics and conserving resources.

Applications of recycled plastic pellets

- Manufacturing of plastic products. Recycled plastic pellets made by plastic film granulators are used to create a wide array of plastic products such as containers, bottles, packaging materials, and household items.

- Construction materials. They are utilized in making construction materials like pipes, decking, panels, and insulation materials.

- Automotive parts. Recycled plastic pellets are employed in producing various automotive components such as bumpers, interior parts, and trim pieces.

- Textiles and fibers. They can be used in the production of synthetic fibers for clothing, carpets, upholstery, and other textile applications.

- Films and sheets. These pellets are utilized in manufacturing plastic films and sheets used in packaging, agriculture (mulching films), and industrial applications.

How to operate a plastic film pelletizing machine?

Do you want to know how to make plastic pellets with this pp/pe film pelletizing machine?

- Cleaning and preparing the machine

- Before operation, ensure the machine is clean and free from debris. Check for any damage or loose components to avoid malfunctions during use.

- Loading the plastic film

- Feed the plastic film into the hopper, typically located at the top of the machine. If using a conveyor, make sure it’s properly aligned with the hopper for smooth feeding.

- Starting the recycling granulator

- Turn on the power switch and set the appropriate working parameters, such as temperature, pressure, and cutting speed, based on the type of plastic film being processed.

- Monitoring during operation

- Continuously observe the machine’s performance. Ensure stable pellet production and watch for abnormal noise or vibration. Adjust parameters as needed to maintain optimal output.

- Emptying the pellets

- After pelletizing is complete, switch off the machine and let it cool down before collecting the finished plastic pellets.

The cost of plastic film pelletizing machine

The cost of a plastic film pelletizing machine can vary depending on several factors, including the size and capacity of the machine, the features and options included, and the brand of the machine. In general, small, single-stage pelletizing machines can be purchased for as little as a few thousand dollars, while large, two-stage machines can cost upwards of several hundred thousand dollars.

Please note that the actual cost of a plastic film pelletizing machine may vary depending on the specific requirements of the buyer. If you want to know the exact price, please contact us and we will recommend the right machine according to your requirements.

How to maintain the plastic film granulator?

- Daily cleaning

- Remove residual plastic from the feed hopper, extruder, die, and discharge bin to prevent blockages and ensure stable output.

- Routine inspection

- Check for wear or damage such as loose bolts, worn belts, or leaking seals. Fix any issues promptly to avoid downtime.

- Lubrication

- Refill oil or grease as specified. Proper lubrication minimizes friction and extends the life of moving parts.

- Tightening and adjustments

- Secure any loose components and adjust belts or chains to maintain correct tension, improving machine reliability and performance.

- Electrical system check

- Inspect wiring and connections for signs of wear or looseness. Ensure all electrical parts are secure and safely insulated.

Conclusion

The Plastic Film Pelletizing Machine is a crucial solution for efficient plastic recycling. By converting waste plastic films into reusable pellets, it not only minimizes environmental impact but also supports sustainable manufacturing.

Additionally, we offer a wide range of recycling equipment to meet different needs. Choose our Plastic Film Pelletizing Machine to enhance your recycling efforts and contribute to a greener future.