The Plastic Pelletizing Recycling Machine efficiently converts plastic waste into reusable plastic pellets. These pellets are small, cylindrical granules that serve as raw materials for producing new plastic products.

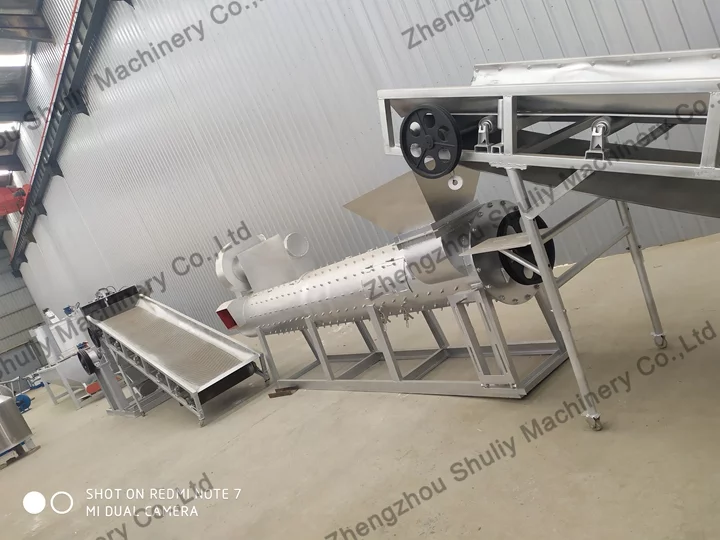

With high-speed shredding, accurate temperature regulation, and an automated pelletizing system, the machine delivers a steady stream of uniform, high-quality pellets suitable for reuse or further manufacturing processes.

Different types of plastic granulators

Plastic pelletizing recycling machines as a common plastic recycling machinery. There are two main types of plastic granulating machines in the market: plastic film granulator machines and EPS pelletizing machines. In the next section, we will introduce these two types of machines in detail.

Plastic film pelletizing machines for sale

- Raw Material: The plastic film granulator processes PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride), and other plastic films commonly found in shopping bags, agricultural films, packaging bags, greenhouse covers, and garbage bags.

- Application Field: It is designed to recycle waste plastic films into reusable granules, widely applied in plastic manufacturing and recycling plants.

- Equipment Structure: The machine is composed of a feeding inlet, reducer, heating device, screw press, pressing chamber, base, motor, die head, and discharge outlet.

- Main Workflow: Plastic film is fed into the extruder, melted by heating, and then extruded through the die to form uniform plastic pellets.

Features of plastic film pelletizing machines

- Wide adaptability of film materials. Designed to handle various types of plastic films, including agricultural films, packaging materials, and more.

- High-efficiency melting and extrusion. It has a heating device that quickly melts and extrudes plastic film to produce high quality pellets.

- Versatile output. Generates pellets that can be used in diverse applications, such as film production, injection molding, and extrusion processes.

- Customization options. Single machine and production line are provided with customized services, and we also provide a one-year warranty period service.

- Machine capacity is 100-500 kg/h. Customers can choose the suitable machine model according to their demand amount.

Foam granulators for sale

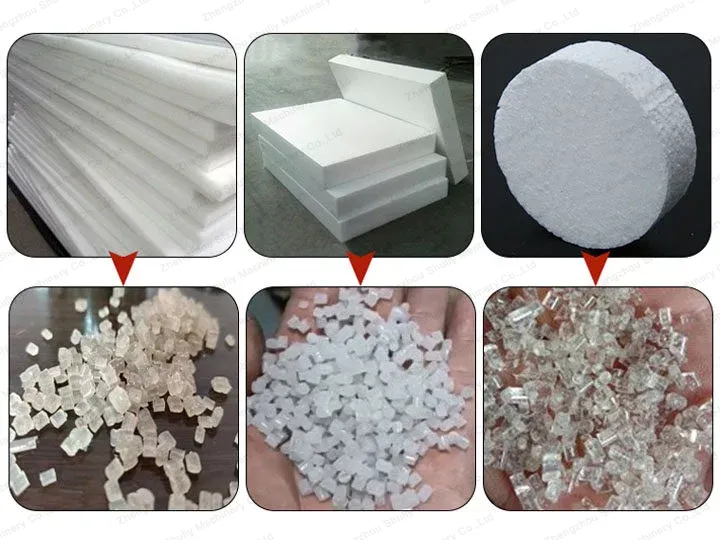

- Raw Material: The EPS foam pelletizing machine recycles EPE and EPS foam materials, including foam food containers, insulation materials, and foam boards.

- Areas of Application: It is widely applied in the industrial, agricultural, and construction sectors.

- Equipment Structure: The main components include the feed inlet, heating device, extruder, screw, and die head, with the extruder serving as the core part.

- Main Workflow: Crushed polystyrene is melted in a heated extruder and extruded through the die into thin strips, which are then cut into uniform pellets using a plastic pellet cutting machine.

Features of EPS foam pelletizing machines

- Reduced bulk. Foam granulators can compress large quantities of styrofoam material up to 40 times for easy storage and transportation.

- High quality output. Produce stable, homogeneous foam pellets for a variety of applications such as molding and other manufacturing processes.

- Energy efficient and environmentally friendly. Efficient processing and granulating of waste foam while saving energy and protecting the environment.

How do you recycle plastic into pellets?

If you want to get high-quality plastic pellets, then you need a plastic granulator machine. A plastic pelletizer machine for plastic recycling can convert various plastic films and EPS/EPS foam into recyclable plastic pellets.

What’s more, all of Shuliy’s plastic pellet making machines are CE certified, with stable product quality and superior performance.

How are plastic granules made?

- Waste plastic is first fed into the crushing machine to be broken into small pieces for further processing.

- The dried plastic pieces are then fed into the extruder of the plastic pelletizing machine for melting and extrusion into thin strips.

- The molten plastic strips pass through a cooling pool to lower their temperature.

- The cooled strips are then cut by the pellet cutter into uniformly sized plastic pellets.

Plastic pelletizing recycling machine manufacturers

- Rich Experience: Shuliy Recycling Machinery has 13 years of R&D and manufacturing experience, cooperating with over 50 countries worldwide.

- Comprehensive Service: Offers one-year warranty, customized production lines, technical support, on-site installation, and lifetime after-sales service.

- Wide Product Range: Provides plastic pelletizing machines, PET washing lines, foam melting machines, EPS compactors, as well as metal, paper, and fiber recycling machines.

If you want to get started in plastic granules industry and are looking for plastic pellet manufacturers, so Shuliy Recycling Machinery is a good choice.

How much does a plastic pelletizing recycling machine price?

The cost of plastic pelletizing recycling machine can vary depending on several factors, including the size, capacity, and features of the machine. However, you can expect to pay anywhere from $2,000 to $20,000 for a basic machine.

Here are some of the factors that affect the cost of a plastic recycling pelletizer machine:

- Size: Larger plastic pelletizer machines cost more due to higher processing capacity.

- Capacity: Higher-capacity machines (kg/h) are pricier as they produce more pellets per hour.

- Features: Extra functions like automatic feeding, water cooling, or noise reduction increase the price.

Conclusion

By choosing Shuliy’s machine, you not only enhance your recycling efficiency but also contribute to a more sustainable and profitable plastic production process. Contact us today to get a personalized quotation and start your plastic recycling business with confidence!