آلة تشكيل دوائر حديد التسليح هي نظام تشكيل قضبان حلزوني مؤتمت بالكامل ومتحكم فيه بواسطة CNC لإنتاج حلقات التثبيت بكميات كبيرة في السكك الحديدية عالية السرعة، ومترو الأنفاق، والطاقة الكهروضوئية، ومشاريع البنية التحتية الأخرى.

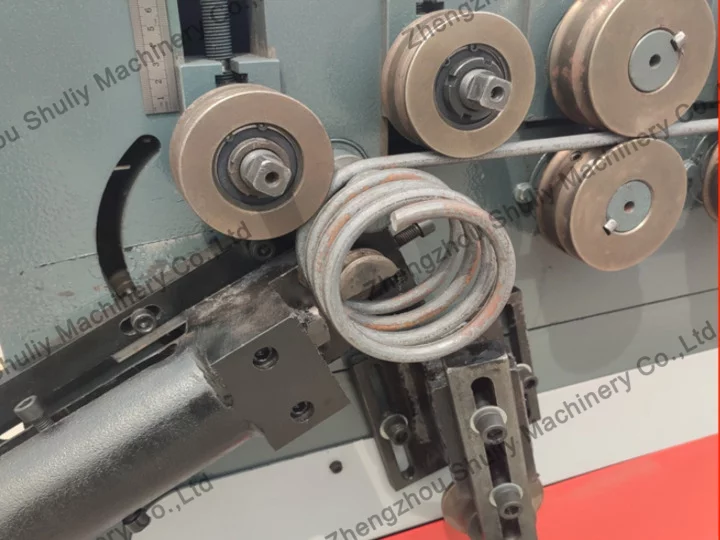

دمج نظام نقل هيدروليكي مدفوع بمحرك كهربائي مع أسطوانات مسبقة الضبط، وعلبة تروس مستقيمة، ووحدة دائرية دقيقة، ووحدة قطع آلية، يقوم باستقامة وثني وقص قضبان الصلب في دفعات مستمرة.

قادرة على إنتاج حلقات نهائية من Ø50 مم حتى Ø3000 مم، وتحافظ على تحمل أبعاد قدره ±0.2 مم طوال العملية بأكملها.

هيكل آلة تشكيل قضبان التسليح الحلزونية

- المحرك الكهربائي يوفر القوة الدافعة الرئيسية.

- مكونات هيدروليكية تشمل مضخة زيت، محرك هيدروليكي، صمامات إلكترونية وأنابيب.

- البكرات القابلة للتعديل مسبقًا لمحاذاة القضبان الأولية.

- علبة تروس الاستقامة لضمان استقامة القضبان بشكل صحيح.

- مجموعة دائرية دقيقة تثني القضبان إلى حلزونات متساوية.

- وحدة قطع أوتوماتيكية تقص كل حلقة إلى الطول المحدد.

- برنامج تحكم CNC يدير جميع الحركات ومعلمات الدفعة لتشغيل سلس.

كيف تعمل آلة تقويس القضبان الفولاذية الأوتوماتيكية بالكامل CNC؟

تعمل آلة تقويس حديد التسليح الأوتوماتيكية بالكامل CNC من خلال نظام متقدم يتم التحكم فيه بواسطة لوحة أم PLC. عند تشغيلها، يقوم المحرك الكهربائي بتشغيل مضخة الزيت لتفعيل النظام الهيدروليكي، والذي بدوره يشغل علبة تروس التقويم. يتم تغذية قضبان الفولاذ للأمام، ومحاذاتها وتقويمها.

بعد ذلك، يتم توجيه القضبان إلى مجموعة الدوائر، حيث يتم ثنيها بدقة إلى الشكل الدائري المطلوب. بعد ذلك، تستخدم وحدة القطع الآلية أسطوانة الزيت لقص القضبان إلى الطول المحدد. تتم عملية التغذية والقطع بالكامل بشكل آلي وتتحكم بها برنامج CNC الكهربائي، مما يسمح بمعالجة الدفعات ويضمن كفاءة عالية ودقة مع الحد الأدنى من التدخل اليدوي.

مزايا آلة صنع دوائر قضبان التسليح

- دقة عالية مع تحمل قدره ±0.2 مم، مما يضمن إنتاجًا متسقًا ودقيقًا.

- متعددة الاستخدامات، قادرة على إنتاج أقطار حلقات نهائية من Ø50 مم إلى Ø3000 مم.

- سرعات معالجة سريعة تتراوح بين 16-30 م/دقيقة للإنتاج العالي والكفاءة.

- تشغيل آلي بالكامل مع تحكم CNC لاستقامة وتشكيل وقص قضبان الصلب.

- متينة وموثوقة، مصممة للاستخدام طويل الأمد مع الحد الأدنى من التوقف.

- محركات موفرة للطاقة توفر أداءً مثاليًا مع تقليل استهلاك الطاقة.

- مثالية للمشاريع الكبيرة مثل السكك الحديدية عالية السرعة، والمترو، وتطبيقات الطاقة الشمسية.

- تصميم مدمج لتركيب وتشغيل موفر للمساحة.

معلمات صانع دوائر الحديد المسلح

| نموذج | قطر الحديد المسلح القابل للتطبيق (مم) | قطر الحلقة النهائية (مم) | إجمالي قدرة المحرك (كيلو واط) | سرعة السفر (م/دقيقة) | خطأ العمل (مم) | أبعاد الآلة (م) | وزن الآلة (كجم) |

|---|---|---|---|---|---|---|---|

| آلة صنع دوائر الحديد المسلح 3-6 | 3-6 | 50-1000 | 4 | 16-25 | ±0.2 | 1.45×0.8×1.2 | 480 |

| آلة صنع دوائر الحديد التسليح 6-10 | 6-10 | 50-800 | 5.5 | 16-25 | ±0.2 | 1.55×0.8×1.3 | 560 |

| آلة صنع دوائر الحديد التسليح 8-12 | 8-12 | 50-1500 | 7 | 16-25 | ±0.2 | 1.55×0.8×1.3 | 640 |

| آلة صنع دوائر الحديد التسليح 10-14 | 10-14 | 50-1800 | 7 | 16-25 | ±0.2 | 1.6×0.8×1.35 | 690 |

| آلة صنع دوائر الحديد التسليح 16-20 | 16-20 | 50-2200 | 11 | 16-30 | ±0.2 | 2.1×0.9×1.5 | 1150 |

| آلة صنع دوائر الحديد التسليح 22-25 | 22-25 | 50-3000 | 15 | 16-30 | ±0.2 | 2.3×0.9×1.7 | 1350 |

أسئلة شائعة حول آلة لف الربيع

هل من السهل تشغيل الآلة وصيانتها؟

نعم، الآلة مؤتمتة بالكامل وتتحكم بها نظام CNC، مما يجعلها سهلة الاستخدام ويقلل من الحاجة للتدخل اليدوي.

ما نوع الدعم المقدم بعد الشراء؟

نحن نقدم دعمًا شاملاً بعد البيع، بما في ذلك تدريب التركيب، وحل المشكلات، وتوافر قطع الغيار. فريقنا ملتزم بضمان تشغيل الآلة الخاصة بك بكفاءة مثلى.

هل يمكن تخصيص الآلة لتلبية احتياجات مشروع محدد؟

نعم، نقدم تكوينات مخصصة مصممة وفقًا لمتطلبات مشروعك، مما يضمن أن تلبي الآلة احتياجات إنتاجك الفريدة.

خاتمة

تتميز آلة تشكيل دوائر حديد التسليح بتصميم معياري موفر للمساحة يندمج بسلاسة في سير عملك وهي مصممة لسهولة الصيانة.

نقدم تكوينات مخصصة لتناسب متطلبات مشروعك الفريدة، بالإضافة إلى تدريب عملي على التركيب وفريق خدمة ما بعد البيع سريع الاستجابة للحفاظ على سير عملك بسلاسة.

بالإضافة إلى آلة تشكيل دوائر حديد التسليح، نوفر أيضًا مجموعة واسعة من معدات معالجة المعادن الأخرى. هل أنت مستعد لتبسيط إنتاج حلقات حديد التسليح الخاصة بك؟ اتصل بنا اليوم للحصول على عرض أسعار مخصص واستشارة خبير.