آلة تحبيب الأفلام البلاستيكية هي مكون حيوي في صناعة إعادة تدوير البلاستيك، مصممة لتحويل الأفلام البلاستيكية بعد الاستهلاك أو بعد الصناعة إلى حبيبات قابلة لإعادة الاستخدام. تقوم هذه الآلة بمعالجة مجموعة واسعة من المواد البلاستيكية بكفاءة، بما في ذلك PP و LDPE والأكياس المنسوجة، من خلال سلسلة من الخطوات مثل الذوبان، والبثق، والتبريد، والقطع.

بتصميمه عالي الأداء وعمليته الفعالة من حيث التكلفة، يمكنه التعامل مع سعات تتراوح من 3000 كجم إلى 7000 كجم في 24 ساعة، مما يجعله خيارًا شائعًا في دول مثل كينيا ونيجيريا. تعمل المكونات الرئيسية للآلة معًا بسلاسة لإنتاج كريات عالية الجودة تُستخدم كمواد خام قيمة لصناعة منتجات بلاستيكية جديدة.

كيف تعمل آلة تحبيب أفلام البلاستيك؟

يريد الكثير من الناس معرفة عملية تحبيب الأفلام البلاستيكية. مبدأ العمل لآلة تكوير الفيلم البلاستيكي بسيط. تقوم الآلة بإذابة الفيلم البلاستيكي عند درجة حرارة عالية، وإدخاله في قالب، ثم تستخدم آلة قطع الحبيبات لتقطيعه إلى كريات بلاستيكية صغيرة.

- قم بتشغيل آلة صنع حبيبات البلاستيك.

- راقب تشغيل آلة الحبيبات، وضعها في الاستخدام بعد التأكد من عدم وجود أصوات أو اهتزازات غير طبيعية.

- سخن الجهاز لإعادة التدوير لذوبان البلاستيك. لاحظ أن درجة الحرارة العالية جدًا ستجعل البلاستيك المنصهر يتحول إلى اللون الأسود، بينما درجة الحرارة المنخفضة جدًا تمنع البلاستيك من الذوبان.

- ضع المادة المسحوقة في منفذ التغذية لآلة تكوير البلاستيك، وأضف جهاز تغذية قسري لمادة الفيلم البلاستيكي لمنع آلات إعادة التدوير من عدم التغذية.

- ينصهر المادة في غرفة الضغط ويتم دفعها باستمرار مع برغي الضغط.

- المادة من المحرك الرئيسي ستدخل مرة أخرى إلى آلة الحبيبات المساعدة للذوبان الثاني والضغط.

- يمكن وضع المادة من المخرج في خزان التبريد للتبريد وقطعها إلى حبيبات صغيرة بواسطة آلة قطع الحبيبات.

تصميم آلة تحبيب أفلام البلاستيك

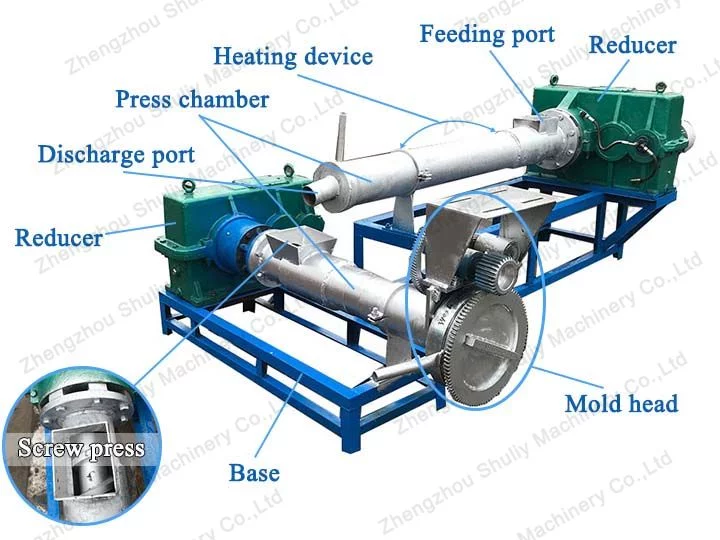

تتكون آلة تحبيب الأفلام البلاستيكية بشكل أساسي من مدخل تغذية، وبرغي، وجهاز تسخين، وغرفة بثق، ورأس قالب تفريغ، ومحرك، ومخفض، وهياكل أخرى.

جسم المحبب البلاستيكي مصنوع من مادة سبائك الصلب، والتي تتميز بمقاومة الحرارة العالية، ومقاومة التآكل العالية، ومقاومة التآكل.

المسمار الموجود داخل الآلة هو الجهاز المستخدم لدفع المادة للأمام. البراغي مصنوعة أيضًا من سبائك الفولاذ المقاومة للتآكل وعالية القوة.

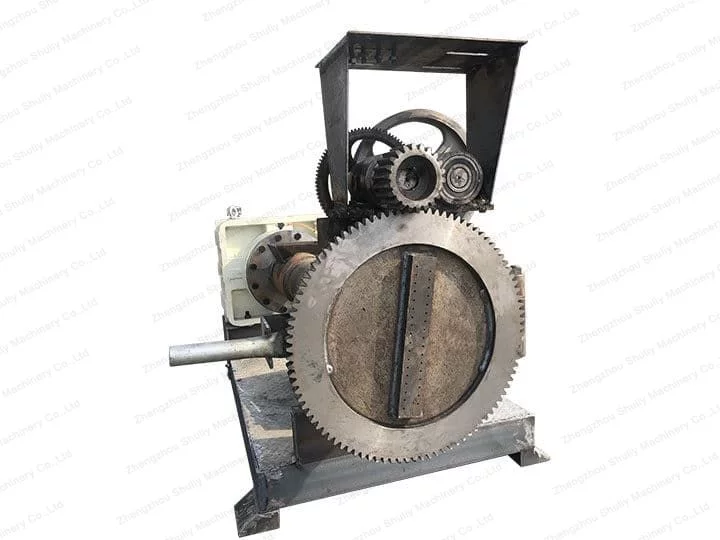

في شركة شولي لصناعة آلات إعادة التدوير، لدينا ثلاثة أنواع من رؤوس القوالب للتفريغ، مثل رؤوس القوالب الكهربائية، ورؤوس القوالب الهيدروليكية، ومرشحات الخبث الأوتوماتيكية.

تم تجهيز رأس الماكينة بجهاز محاذاة المطحنة لتصحيح تركيز فتحة التفريغ ورأس القالب.

تم تجهيز الماكينة أيضًا بجهاز تبريد للتخلص من الحرارة الزائدة الناتجة عن الاحتكاك الدوار للمسمار. وهذا يمنع درجات الحرارة المفرطة التي يمكن أن تسبب بعض المشاكل غير المرغوب فيها.

مواصفات آلة تحبيب أفلام البلاستيك

| نموذج | القدرة (طن / يوم) | المحرك الرئيسي (كيلوواط) | قطر المسمار (مم) | سرعة العمود الرئيسي (دقيقة) |

| SL-125 | 3 | 22+1.5 كيلو واط | 125 | 50-70 |

| SL-150 | 5 | 30+1.5 كيلو واط | 150 | 40-60 |

| SL-180 | 7 | 45 كيلو واط | 180 | 40-50 |

يمكن لجهاز تقطيع الأفلام البلاستيكية من شولي إنتاج ما يصل إلى 7 طن في الساعة. يمكن أن يلبي ذلك متطلبات الإنتاج لمعظم مصانع إعادة تدوير الأفلام البلاستيكية. إذا كانت لديك متطلبات أخرى من حيث الإنتاجية، يرجى الاتصال بنا.

ما هي فوائد استخدام آلة حبيبات أفلام PE؟

- توافق واسع مع المواد

- مناسبة لأفلام PE وPP وPET وأنواع الأفلام الأخرى - مثالية لاحتياجات إعادة التدوير المتنوعة.

- تقليل النفايات بشكل فعال

- تحول نفايات الأفلام إلى حبيبات، مما يقلل من تأثير مدافن النفايات والحرق.

- ناتج قابل لإعادة التدوير لمنتجات جديدة

- تنتج حبيبات قابلة لإعادة الاستخدام، مما يقلل الاعتماد على البلاستيك الخام ويحافظ على الموارد.

تطبيقات حبيبات البلاستيك المعاد تدويرها

- تصنيع المنتجات البلاستيكية. يتم استخدام حبيبات البلاستيك المعاد تدويرها التي تصنعها مكائن تقطيع الأفلام البلاستيكية لإنشاء مجموعة واسعة من المنتجات البلاستيكية مثل الحاويات والزجاجات ومواد التعبئة والتغليف والأدوات المنزلية.

- مواد البناء. يتم استخدامها في صنع مواد البناء مثل الأنابيب، والأرضيات، والألواح، ومواد العزل.

- قطع غيار السيارات. يتم استخدام حبيبات البلاستيك المعاد تدويرها في إنتاج مكونات السيارات المختلفة مثل الصدامات، وأجزاء الداخلية، وقطع الزينة.

- الأقمشة والألياف. يمكن استخدامها في إنتاج الألياف الاصطناعية للملابس، والسجاد، والأثاث، وتطبيقات النسيج الأخرى.

- الأفلام والأوراق. تُستخدم هذه الكريات في تصنيع الأفلام والأوراق البلاستيكية المستخدمة في التعبئة والتغليف والزراعة (أفلام التغطية) والتطبيقات الصناعية.

كيف تعمل آلة تشكيل حبيبات الأفلام البلاستيكية؟

هل تريد أن تعرف كيفية صنع الكريات البلاستيكية باستخدام آلة تكوير الفيلم pp/pe؟

- تنظيف وتحضير الآلة

- قبل التشغيل، تأكد من أن الآلة نظيفة وخالية من الحطام. تحقق من أي تلف أو مكونات فضفاضة لتجنب الأعطال أثناء الاستخدام.

- تحميل الفيلم البلاستيكي

- قم بإدخال الفيلم البلاستيكي في القادوس، الذي يقع عادة في الجزء العلوي من الآلة. إذا كنت تستخدم حزام ناقل، تأكد من أنه متماشي بشكل صحيح مع القادوس لتغذية سلسة.

- بدء تشغيل آلة إعادة تدوير الحبيبات

- قم بتشغيل مفتاح الطاقة واضبط معلمات العمل المناسبة، مثل درجة الحرارة والضغط وسرعة القطع، بناءً على نوع فيلم البلاستيك الذي يتم معالجته.

- المراقبة أثناء التشغيل

- راقب أداء الآلة باستمرار. تأكد من استقرار إنتاج الكريات وراقب أي ضوضاء أو اهتزاز غير طبيعي. قم بضبط المعلمات حسب الحاجة للحفاظ على الإنتاج الأمثل.

- إفراغ الحبيبات

- بعد الانتهاء من عملية تشكيل الحبيبات، قم بإيقاف تشغيل الآلة واتركها تبرد قبل جمع حبيبات البلاستيك النهائية.

تكلفة آلة تكوير أفلام البلاستيك

يمكن أن تختلف تكلفة آلة تكوير الأفلام البلاستيكية اعتمادًا على عدة عوامل، بما في ذلك حجم الماكينة وقدرتها، والميزات والخيارات المضمنة، والعلامة التجارية للآلة. بشكل عام، يمكن شراء آلات التكوير الصغيرة ذات المرحلة الواحدة مقابل بضعة آلاف من الدولارات، في حين أن الآلات الكبيرة ذات المرحلتين يمكن أن تكلف ما يصل إلى عدة مئات الآلاف من الدولارات.

يرجى ملاحظة أن التكلفة الفعلية لآلة تكوير الأفلام البلاستيكية قد تختلف وفقًا للمتطلبات المحددة للمشتري. إذا كنت تريد معرفة السعر الدقيق، يرجى الاتصال بنا وسنوصي بالجهاز المناسب وفقًا لمتطلباتك.

كيف تحافظ على آلة تكوير الأفلام البلاستيكية؟

- التنظيف اليومي

- قم بإزالة البلاستيك المتبقي من قادوس التغذية، والمكبس، والقالب، وصندوق التفريغ لتجنب الانسدادات وضمان استقرار الإنتاج.

- الفحص الروتيني

- تحقق من التآكل أو التلف مثل البراغي الفضفاضة، والأحزمة البالية، أو التسريبات في الأختام. قم بإصلاح أي مشاكل على الفور لتجنب التوقف.

- تشحيم

- قم بإعادة تعبئة الزيت أو الشحم كما هو محدد. يقلل التشحيم الجيد من الاحتكاك ويطيل عمر الأجزاء المتحركة.

- تشديد وتعديلات

- قم بتأمين أي مكونات فضفاضة وضبط الأحزمة أو السلاسل للحفاظ على التوتر الصحيح، مما يحسن من موثوقية الآلة وأدائها.

- فحص النظام الكهربائي

- افحص الأسلاك والاتصالات بحثًا عن علامات التآكل أو الانفصال. تأكد من أن جميع الأجزاء الكهربائية مؤمنة ومعزولة بأمان.

خاتمة

آلة تكوير الأفلام البلاستيكية هي حل حاسم لإعادة تدوير البلاستيك بكفاءة. من خلال تحويل نفايات الأفلام البلاستيكية إلى كريات قابلة لإعادة الاستخدام، فإنها لا تقلل فقط من الأثر البيئي ولكنها تدعم أيضًا التصنيع المستدام.

بالإضافة إلى ذلك، نقدم مجموعة واسعة من معدات إعادة التدوير لتلبية الاحتياجات المختلفة. اختر آلة تحبيب الأفلام البلاستيكية الخاصة بنا لتعزيز جهود إعادة التدوير والمساهمة في مستقبل أكثر اخضرارًا.