The textile cutting machine can efficiently process a wide range of waste fiber materials, including old clothes, cotton wool, linen, leather, plastic film, and more. It reduces bulky textiles into uniform pieces, making them easier for recycling, stuffing, or further processing.

Shuliy provides five models of fiber cutting machines with capacities from 300–5000 kg/h, suitable for both small and large-scale operations. The machine allows flexible adjustment of output, with cutting sizes from 5–300 mm and thicknesses from 20–200 mm, meeting diverse customer needs.

With its broad applications, adjustable cutting specifications, and high processing efficiency, the Shuliy textile cutting machine offers a reliable solution for maximizing the value of textile waste and promoting resource recycling.

Raw materials and application areas of textile cutting machines

Textile cutting machines can cut chemical fiber, cotton yarn, old clothes, cotton wool, chemical fiber, linen, leather, plastic film, paper, trademark signs, non-woven fabrics, and many other materials.

Textile cutting machines are used in various industrial sites, including garment manufacturing, upholstery, and furniture production, automotive interiors, aerospace materials, industrial textiles, and recycling facilities.

Key features of the fiber cutting machine

- Adjustable cutting size. The cutting size is between 5-300 mm, and the cutting size can be adjusted by changing the blade.

- Various models for sale. We have 5 types of automatic textile cutting machines for customers to choose from, which can meet the processing capacity of 300-5000 kg/h.

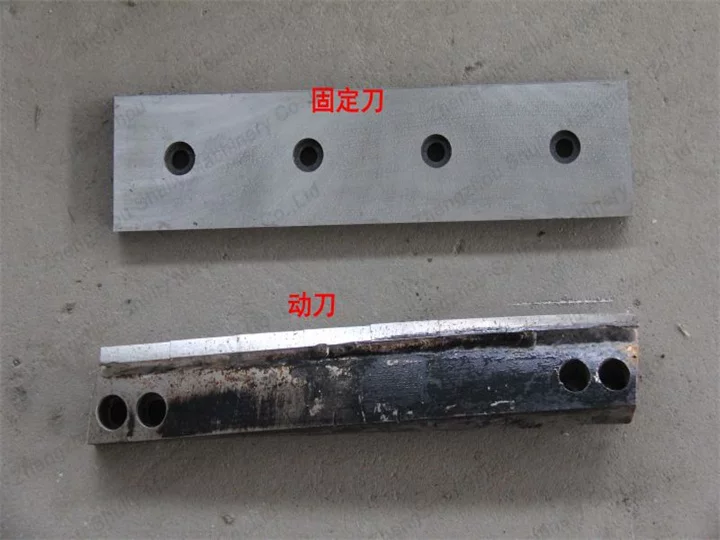

- The blade has high hardness. The machine’s cutter is made of tool steel. It is strong and durable.

- Excellent cutting thickness. Our machines can cut materials with a thickness between 20-200 mm.

- Clean edges. The finished product after cutting has smooth edges and no burrs. It reduces the work of subsequent processing.

Parameters of automatic textile cutting machine

| Model | SL-500 | SL-800 | SL-1200 | SL-1600 | SL-2400 |

| Capacity(kg/h) | 300-500 | 500-800 | 800-1200 | 1000-3000 | 2000-5000 |

| Cutting size(mm) | 5-150 | 5-150 | 5-150 | 5-300 | 10-300 |

| Knife material | Alloy tool steel | Alloy tool steel | Alloy tool steel | Alloy tool steel | Alloy tool steel |

| Output belt(mm) | 2800×350 | 2800×350 | 3000×520 | 3000×720 | 3000×110 |

| Input belt(mm) | 2800×350 | 2800×350 | 3000×520 | 3000×720 | 3000×110 |

| Cutting thickness(mm) | 20 | 30-50 | 30-80 | 20-150 | 30-200 |

These are the parameters of 5 popular rag shredders. In addition to these 5 models, we can also provide customized services according to the customer’s processing capacity. If you are looking for a high quality fiber cutting machine, please feel free to contact us.

How does a cutting machine for textile work?

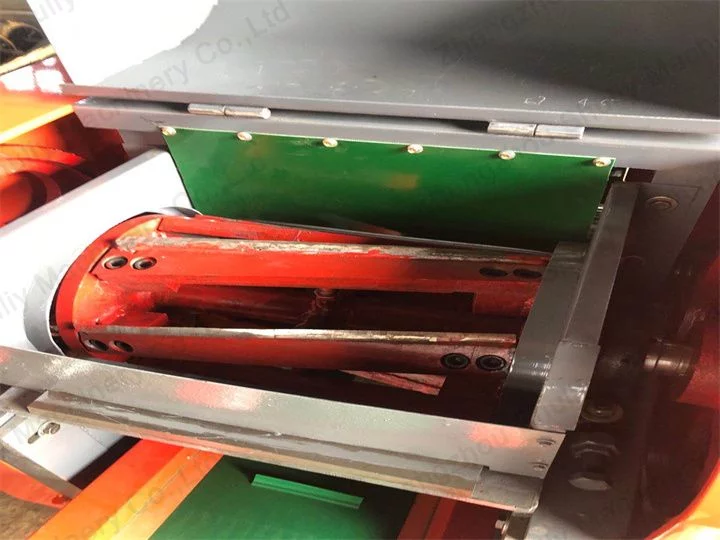

The cnc textile cutting machine is equipped with two fixed blades and four movable blades. The heart of its operation lies in the high-speed rotation of the movable blade rollers.

As the raw material passes through the fixed blade, the spinning movable blades swiftly and precisely cut it into small pieces. The cutting effect is not only fast and efficient, but also the finished edge is smooth and burr free.

Using tips of the automatic textile cutting machine

Operating an automatic fiber sheet cutting machine safely is paramount. Here are some things that you need to know.

- Receive proper training in machine operation and safety procedures.

- Wear appropriate personal protective equipment, including safety glasses and gloves.

- After the raw material is sheared, the feeding motor can be turned off. Then turn off the shearing main motor. Finally, cut off the power supply.

- During the shearing process, if the material wraps around the roller, blocks the edge of the conveyor belt, or causes abnormal noise, please press the emergency stop button.

Textile cutting machine faqs

What is the price of a textile cutting machine?

The price of a textile waste cutting machine depends on its type, features, and capacity. Entry-level models cost a few thousand dollars, while advanced laser cutters are higher.

Shuliy offers 5 styles of fiber cutting machines, and you can choose according to your capacity or budget. For detailed quotes, please contact us.

What is the maintenance method of textile cutting machine?

- Cleaning and lubricating moving parts.

- Checking blade sharpness and replacing them when necessary. But we recommend that you have a sharpening machine to minimize the cost of replacing your blades.

- Inspecting belts, motors, and electrical components.

- Calibrating the waste cloth cutting machine for accuracy.

- Clean the materials from the gaps between the upper and lower pressure rollers, the knife holder, and the conveyor belt.

Where to buy a automatic textile cutting machine?

Shuliy Machinery has over 10 years of experience in recycling equipment manufacturing and export.

As a professional textile cutting machine supplier, we provide efficient fiber cutting solutions with customization options, including conveyor size, plugs, and voltage.

Contact us via email or WhatsApp for details!

Contact us now!

With its wide material adaptability, flexible cutting specifications, and reliable performance, the Shuliy textile cutting machine is an ideal choice for businesses engaged in textile recycling and fiber processing.

Fiber cutting machine can be used with many recycling plants of fiber opening machine and fiber carding machine, clothing baler and other machines to treat fiber materials, which all are important equipment for waste textile recycling production line.

Contact us today to get a customized solution and quotation for your textile waste recycling project!