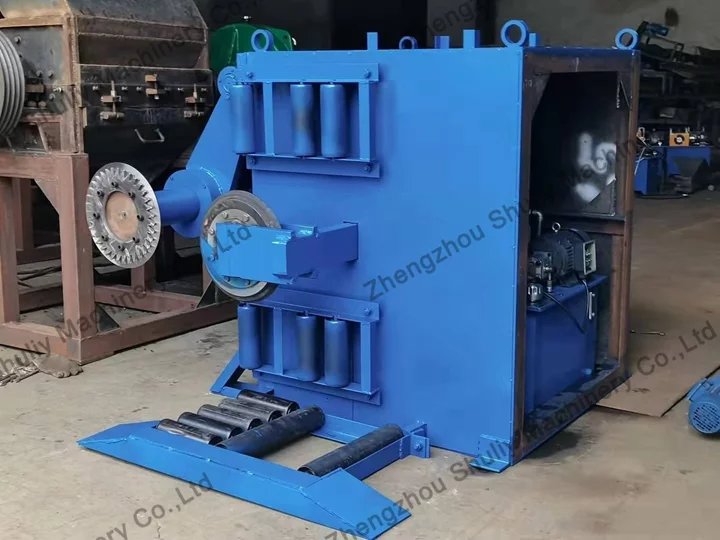

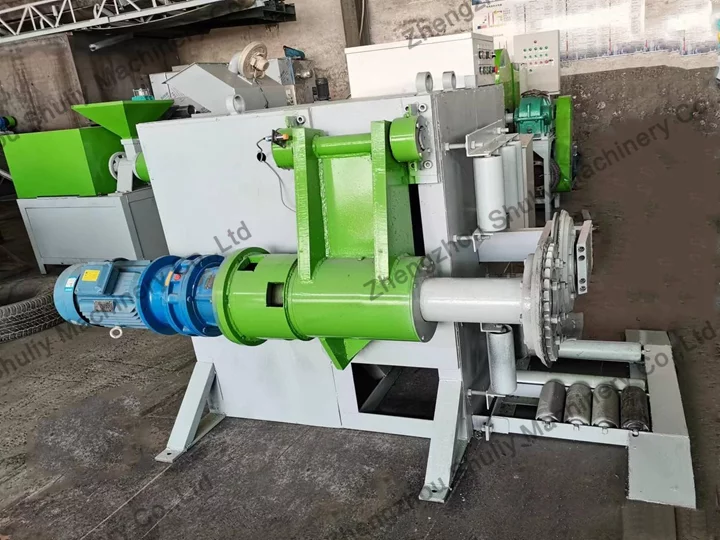

The Tire Half Cutting Machine is a specialized piece of equipment for the pre-processing of waste tires in rubber recycling operations. Its main function is to cut a whole tire into two equal pieces from the middle, making the tire easier to handle and prepare for further processing such as shredding, crushing, or rubber powder production. The machine uses a hydraulic-driven circular disc blade, ensuring clean cuts, stable operation, and high working efficiency.

This machine is suitable for handling tires with a diameter of less than 1400 mm, covering most commonly recycled passenger and truck tires. With a processing capacity of 2–3 tires per minute, it meets the demands of continuous and large-scale recycling lines. The equipment is powered by 4 kW + 3 kW motors, operating on 380 V, 50 Hz, which provides sufficient cutting force while maintaining energy-efficient performance.

Widely used in waste tire recycling plants, environmental protection projects, and rubber regeneration facilities, this machine serves as an essential front-end solution for improving recycling efficiency and reducing environmental impact.

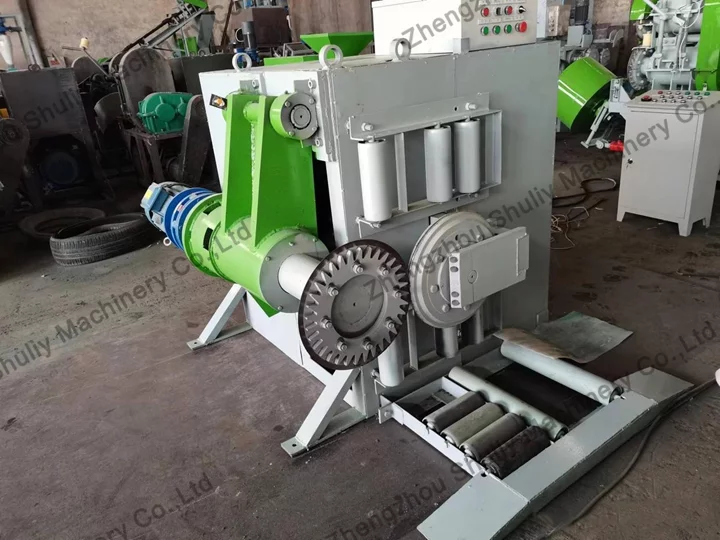

Tire splitter machine advantages

- High Efficiency: Capable of cutting the beads of dolly tires quickly, significantly improving productivity in tire ring separation.

- Fast Operation for Unicycle Tires: Can process unicycle tires with diameters of 600–800 mm, completing bead cutting in just 5 seconds.

- Enhanced Overall Efficiency: Rapid cutting reduces processing time, enabling faster workflow and higher throughput.

- User-Friendly Control: Equipped with a distribution box control system, ensuring simple, safe, and easy operation.

- Versatile Application: Suitable for various tire types, including dolly and unicycle tires, making it adaptable to different recycling needs.

- Improved Safety: Hydraulic-driven cutting and controlled operation minimize risks during the splitting process.

Tire half cutting machine working principle

The Tire Half Cutting Machine operates on a hydraulic-driven cutting principle, combining precision mechanics with controlled force to safely and efficiently split tires. When the machine is activated, the hydraulic system powers a high-strength circular disc blade to move steadily toward the tire. The tire is first securely clamped in place to prevent slipping or deformation during the cutting process.

As the blade advances, it slices through the tire’s tread and sidewall evenly, splitting the tire into two symmetrical halves. The hydraulic system ensures consistent cutting pressure, smooth motion, and minimal vibration, allowing for clean, accurate cuts while reducing wear on the blade and improving overall operational safety.

This principle enables the machine to handle various tire types and sizes efficiently, making it an essential pre-processing tool in tire recycling operations.

What is the price of the tire cutter?

The price of a Tire Cutter can vary depending on factors such as machine size, cutting capacity, automation level, and additional features.

For example, machines designed for small to medium passenger tires may be more affordable, while heavy-duty models capable of processing truck or construction tires typically come at a higher cost. Other factors influencing the price include the quality of the hydraulic system, blade materials, and included safety or control features.

We offer a range of tire cutting solutions to meet different production needs and budgets, and our team can provide a customized quote based on your specific requirements, tire types, and processing capacity. This ensures you get the most suitable machine at a competitive price.

Tyre half cutter faqs

What types of tires can this machine handle?

In addition to regular small and medium passenger car tires, this machine can also process truck tires, construction vehicle tires, and some motorcycle tires, making it highly versatile.

Is the machine difficult to operate? Do I need professional personnel?

The machine is designed with a hydraulic and electric control system, featuring an intuitive interface. Most operations can be learned with simple training, without requiring specialized skills.

Will the tire slip or deform during cutting?

The machine is equipped with a dedicated clamping device to securely hold the tire, effectively preventing slipping or deformation and ensuring precise cutting.

Does the machine overheat or have a high failure rate during continuous operation?

The machine uses a high-performance hydraulic system and wear-resistant blades, allowing long-term continuous operation. Regular maintenance ensures a low failure rate.

Can the cut tire halves be used directly for subsequent shredding or rubber powder processing?

Yes. The cut tires are halved and uniformly shaped, making them ideal for further crushing, grinding, or rubber recycling processes, improving production line efficiency.

Tire half cutting machine parameters

| Function | Cut the whole to 2 pieces from the middle |

| Tire diameter | <1400mm |

| Capacity | 2-3pcs/min |

| Power | 4kw+3kw , 380v, 50hz |

| Dimension | 1850*1450*1500mm |

| Weight | 1200kg |

Conclusion

In summary, the Tire Half Cutting Machine is a reliable, efficient, and user-friendly solution for pre-processing waste tires. By halving tires cleanly and safely, it not only improves processing efficiency but also supports sustainable tire recycling efforts.

In addition to the Tire Half Cutting Machine, we also offer a range of other tire processing equipment, providing complete solutions to meet various tire recycling and disposal needs.