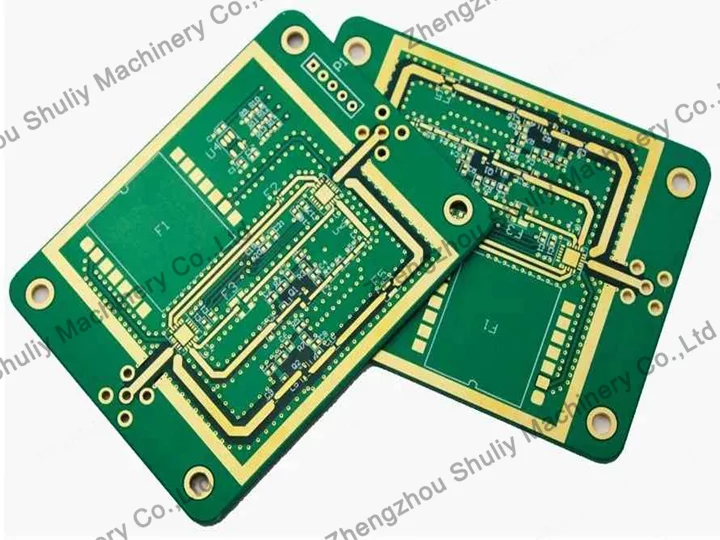

The Waste Circuit Boards Recycling Machine is a complete, intelligent recycling solution for efficient separation and recovery of metals and non-metals from electronic waste. By integrating shredding, crushing, fine grinding, air separation, electrostatic sorting, and dust removal into one automated production line, the machine enables stable operation with a metal recovery rate of over 99% under optimized conditions.

Controlled by a PLC system with a touch-screen interface, the equipment ensures uniform feeding, coordinated processing, and reliable performance. It is widely used for processing waste printed circuit boards, copper-clad laminates, damaged circuit boards, and production scraps, allowing valuable metals to be recovered while non-metal materials such as resin powder are collected for reuse or compliant disposal.

Suitable for e-waste recycling plants, PCB manufacturing waste treatment, and electronic recycling projects, this machine supports both environmental protection and resource regeneration.

PCB crusher and separator applications

The PCB crusher and separator is mainly applied in the recycling and treatment of various electronic waste materials, including discarded printed circuit boards, copper-clad laminates, defective circuit boards, and leftover scraps from PCB manufacturing.

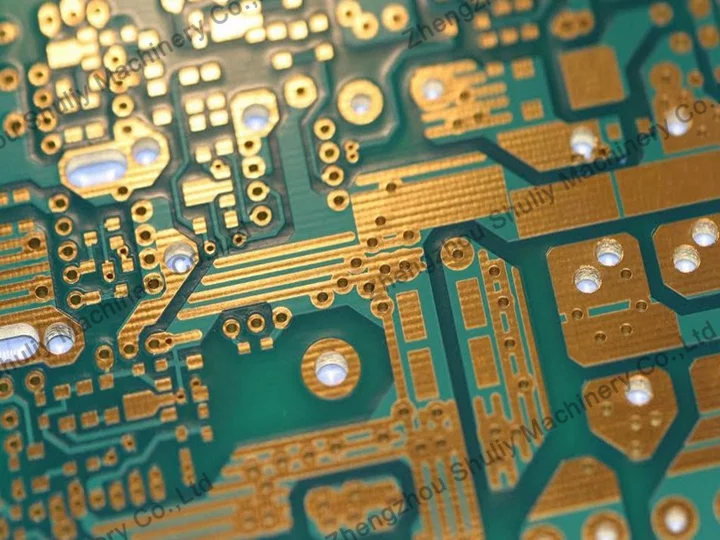

Through crushing and precise separation processes, the equipment effectively divides metallic components from non-metal materials, enabling the recovery of valuable metals while collecting resin powder as a separate output.

This machine is suitable for electronic waste recycling plants, PCB factories, and resource recovery projects that require efficient material separation and improved recycling value.

Waste circuit boards recycling machine working flow

- Waste circuit boards are first fed into a shredder for initial size reduction.

- The shredded materials are then processed by a hammer crusher to achieve finer crushing.

- Crushed particles enter a water-cooled mill with rotary screening, which controls particle size and prevents overheating during grinding.

- An air separation system is used to separate heavy metal particles from lighter non-metal materials.

- The airflow and fine dust generated in the process are collected and treated by a dust removal system to maintain a clean working environment.

- Non-metal materials containing trace metal powder are further refined through an electrostatic sorting machine.

- Finally, metal powder and non-metallic resin powder are obtained separately with high purity.

Waste circuit boards recycling machine for sale

The Waste Circuit Boards Recycling Machine for sale is designed with a magnetic iron separation conveyor in the middle of the production line, which effectively removes ferrous materials to protect downstream equipment and improve overall separation efficiency.

The final discharge system is clearly divided, with one outlet for mixed metal and plastic materials and another outlet dedicated to resin powder, ensuring organized material collection.

Operating with a fully enclosed structure and an integrated dust removal system, the entire recycling line runs in a dust-free and pollution-free manner. In addition, the finished material particle size is controlled to less than 1 mm, meeting the requirements for fine separation and high-value recycling applications.

Waste circuit boards recycling machine advantages

- Intelligent automatic control: The complete recycling line is operated through PLC-based automation combined with a touch screen interface, ensuring continuous, stable feeding and smooth coordination between each processing unit.

- Compact and stable design: The machine features a space-saving structure with a well-organized layout, delivering reliable performance while minimizing operating noise during crushing.

- Multi-stage crushing with cooling system: Shredding, crushing, and fine grinding are carried out step by step, while a circulating water cooling system protects the crushing chamber and maintains long-term stable operation.

- Clean and safe working environment: A negative-pressure material conveying system together with an efficient pulse dust collection unit significantly reduces dust emissions and improves workplace cleanliness.

- High metal recovery efficiency: Advanced gravity separation combined with electrostatic separation technology allows effective metal and non-metal separation, achieving a metal recovery rate of over 99%.

PCB recycling machine parameters

| Model | Power | Recovery percent | Collection coefficient | Output | External dimension | Weight |

| SL-1000 | 45kw | ≧98% | ≧99% | 150-200kg/h | 6000*7500*4200mm | 4250kg |

| SL-1500 | 68kw | 200-300kg/h | 7000*8200*4500mm | 6500kg | ||

| SL-1800 | 110kw | 300-500kg/h | 8000*11000*4800mm | 8500kg | ||

| SL-2000 | 198kw | 1000-1200kg/h | 8200*16000*5250mm | 12500kg |

Supporting equipment of waste circuit boards crusher and separator

For high-volume clients, the waste circuit boards recycling machine can be used in conjunction with a metal shredder to achieve a more efficient processing workflow.

This supporting equipment can perform preliminary crushing of waste circuit boards and physically separate metal from non-metal materials, reducing the load on the recycling machine and improving overall capacity and recovery efficiency.

It is especially suitable for businesses or recycling plants with large amounts of electronic waste and high processing requirements, significantly optimizing production processes, reducing labor costs, and ensuring the consistency and usability of recovered materials.

Conclusion

To meet the diverse needs of our clients, our Waste Circuit Boards Recycling Machine is not only efficient and reliable but can also work in tandem with a metal shredder for high-volume processing. Whether handling small amounts of electronic waste or large-scale factory boards, we provide professional solutions.

In addition, our company offers a wide range of metal recycling equipment, covering the recovery and processing of scrap copper, aluminum, and other non-ferrous metals. You are warmly invited to contact us for a quote and choose the recycling equipment that best suits your needs, making your recycling operations more efficient and cost-effective.