Эти четыре машины — полностью автоматическая ЧПУ машина для гибки стальных прутков с пятью головками, автоматическая ЧПУ машина для гибки стальных прутков, ЧПУ машина для гибки труб и гидравлическая машина для гибки стальных каналов Н-образной формы — все они эффективны, точны и адаптируемы к различным промышленным потребностям в гибке.

Полностью автоматическая станок для гибки стальных прутков с пятью головками оснащен автоматическим позиционированием, резкой на фиксированную длину и блокировкой, с мощностью 8 кВт и высокой эффективностью. Автоматическая станция для гибки стальных прутков с ЧПУ доступна в различных моделях для удовлетворения различных потребностей в гибке арматуры.

ЧПУ трубогиб предназначен для гибки труб различных диаметров и широко используется во многих отраслях. Гидравлическая машина для гибки канального стального H-образного профиля, оснащенная гидравлической высокомощной трансмиссионной системой, идеально подходит для специальных применений, таких как арочная поддержка U-образного профиля в туннелях.

Полностью автоматическая CNC машина для изгиба стальных прутков с пятью головками

Полностью автоматические CNC машины для гибки стальных прутков с пятью головками являются современными инструментами для эффективной обработки стальных прутков в строительстве и инженерных проектах. Они обычно используются на крупных строительных площадках, таких как здания, мосты, железные дороги, автомагистрали и другие инфраструктурные проекты, где требуется гибка стальных прутков в больших объемах и с высокой точностью.

Особенности машины для гибки стальных прутков

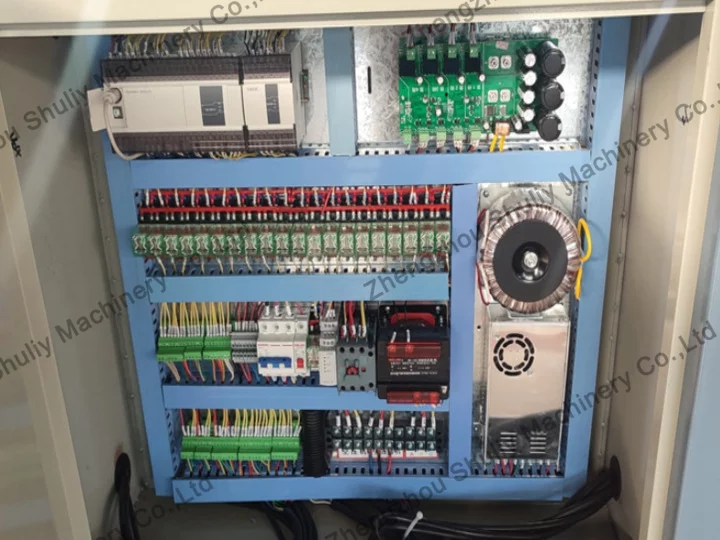

- Автоматизированные функцииЭта машина предлагает автоматическую позиционирование, резку фиксированной длины и функции блокировки. Она может автоматически позиционировать и резать стальные прутки до желаемой длины, а затем фиксировать их на месте для изгиба.

- Многофункциональная работа. Оснащенная пятью головками, она может одновременно изгибать несколько стальных прутков, значительно увеличивая эффективность работы и производительность.

- Гидравлическая система. Машина использует гидравлическую систему давления 5-16Mpa, обеспечивая мощное усилие для изгиба стальных прутков различных диаметров.

- Регулируемые параметрыПараметры, такие как гидравлическое давление, метод подбора размеров (ручной/автоматический) и мощность машины (8 кВт), могут быть отрегулированы в зависимости от различных требований к обработке.

- Высокая эффективность обработки. Со скоростью формирования 5 секунд и производительностью 1500-2000 штук в час, она может быстро выполнять задачи.

- Высокая точность. Ошибка угла контролируется в пределах ±1°, что обеспечивает высокоточные результаты изгиба.

- Стабильный и долговечный. Весом около 1200 кг, машина предлагает стабильность во время работы и построена для долговечности.

- Универсальные примененияОн широко используется для изгиба стальных прутьев в различных строительных проектах, включая, но не ограничиваясь, жилыми зданиями, коммерческими комплексами, мостами, туннелями и многим другим.

Параметры CNC машины для гибки стальных прутков с пятью головками

- Гидравлическое давление: 5-16 МПа

- Метод размерения: ручной/автоматический

- Мощность машины: 8 кВт

- Давление воздуха: 0,4-0,6 МПа

- Скорость формования: 5 секунд

- Производительность: 1500-2000/час

- Блокировка машины: гидравлическая блокировка

- Угол ошибки: ± 1°

- Вес машины: 1200 кг

Автоматическая CNC машина для гибки стальных прутков

Автоматическая машина для гибки стальных прутков с ЧПУ - это универсальный инструмент, предназначенный для эффективной гибки стальных прутков в строительстве и инженерных приложениях. Эта машина идеально подходит для использования в строительстве зданий, инфраструктурных проектах и других ситуациях, где требуется точная и массовая гибка стальных прутков.

Преимущества настольной CNC машины для гибки стальных прутков

- Широкий ассортимент моделейДоступно несколько моделей, включая Модель 40, Модель 40H, Модель 42, Модель 45, Модель 45(CNC), Модель 50, Модель 50(CNC), Модель 60 и Модель 60(CNC). Каждая модель соответствует различным требованиям и возможностям гибки.

- Возможность изгиба. Диапазон изгиба варьируется в зависимости от модели. Например:

- Модель 40: Изгибает круглую сталь ≤32мм и резьбовую сталь ≤28мм.

- Модель 45: Изгибает круглую сталь <40мм и резьбовую сталь ≤34мм.

- Модель 50: Изгибает круглую сталь ≤50мм и резьбовую сталь ≤45мм.

- Модель 60: Изгибает круглую сталь <60мм и резьбовую сталь <50мм.

- Мощные моторыОснащены высококачественными моторами, такими как 3-киловаттные медные моторы для меньших моделей и до 5.5-киловаттные моторы для больших моделей, обеспечивающие достаточную мощность для операций гибки.

- Стабильная производительность. Машины разработаны с учетом стабильности, с весом от 220кг до 425кг, что обеспечивает плавную работу.

- Компактный дизайн. Общие размеры машин относительно компактны, что делает их подходящими для различных рабочих условий.

- Постоянная скорость изгиба. Все модели имеют скорость изгиба 12 изгибов в минуту, что обеспечивает эффективную обработку.

- Опции ЧПУ. Некоторые модели оснащены возможностями ЧПУ, что повышает автоматизацию и точность в процессах изгиба.

- Трехфазное питание. Все модели используют трехфазное питание 380В, что обеспечивает стабильную работу.

Параметры машины для гибки стальных прутков

| Модель | Диапазон изгиба (круглая сталь) | Диапазон изгиба (резьбовая сталь) | Скорость изгиба (в минуту) | Входное напряжение | Общий размер (мм) | Мощность мотора | Скорость мотора (об/мин) | Общий вес (кг) |

|---|---|---|---|---|---|---|---|---|

| Модель 40 | ≤32мм | ≤28мм | 12 | Трехфазный 380В | 810*760″830 | 3кВт (медный провод) | 1440 | 220 |

| Модель 40H | ≤34мм | ≤32мм | 12 | Трехфазный 380В | 830*770*830 | 3кВт (медный провод) | 1440 | 255 |

| Модель 42 | ≤34мм | ≤32мм | 12 | Трехфазный 380В | 830*750*840 | 3кВт (медный провод) | 1440 | 270 |

| Модель 45 | <40мм | ≤34мм | 12 | Трехфазный 380В | 850*750*830 | 4кВт (медный провод) | 1440 | 290 |

| Модель 45 (ЧПУ) | <40мм | ≤34мм | 12 | Трехфазный 380В | 850*750*830 | 4кВт (медный провод) | 1440 | 300 |

| Модель 50 | ≤50мм | ≤45мм | 12 | Трехфазный 380В | 950*850*850 | 4 кВт (стальная проволока) | 1440 | 320 |

| Модель 50 (ЧПУ) | ≤30мм | ≤28мм | 12 | Трехфазный 380В | 950*850*850 | 4 кВт (стальная проволока) | 1440 | 325 |

| Модель 60 | <60мм | <50мм | 12 | Трехфазный 380В | 1050*870*900 | 5.5 кВт (национальный стандарт) | 1440 | 420 |

| Модель 60 (ЧПУ) | <60мм | <50мм | 12 | Трехфазный 380В | 1050*870*900 | 5.5 кВт (национальный стандарт) | 1440 | 425 |

Станок для гибки труб с ЧПУ

Станки для гибки труб с ЧПУ - это машины с числовым программным управлением, предназначенные для гибки труб. Они обеспечивают высокую точность, эффективность и универсальность.

Особенности станка для гибки труб с ЧПУ

- Точная гибка труб различных диаметров и материалов.

- Управление с ЧПУ обеспечивает высокую точность и согласованность.

- Идеально подходит для сложных задач гибки с несколькими изгибами.

- Снижает необходимость в ручном вмешательстве, повышая эффективность и уменьшая ошибки.

- Широко используется в автомобилестроении, аэрокосмической и строительной отраслях.

Оснащенные современными системами управления, они могут обрабатывать трубы различных диаметров, от 10-24 мм до 40-100 мм. Они могут изгибать трубы с высокой точностью и стабильностью. Их гидравлические системы обеспечивают мощную силу. Они могут обрабатывать трубы из различных материалов, включая сталь, нержавеющую сталь и алюминий. Они подходят для производства выхлопных труб, топливных труб и труб для кондиционирования воздуха.

Они могут изгибать трубы под различными углами, от 0 до 180 градусов. Они могут обрабатывать трубы с различной толщиной стенок. Их конструкция обеспечивает стабильную работу и долгий срок службы. Двигатели соответствуют национальным стандартам. Их трехфазное питание 380 В обеспечивает стабильную работу. Они широко используются во многих отраслях.

Параметры станка для гибки труб с ЧПУ

| Модель | Диапазон гибки | Диапазон углов | Основная скорость | Размер машины | Толщина стенки | Мощность мотора | Входное напряжение | Вес машины |

|---|---|---|---|---|---|---|---|---|

| Модель 38 | 10-24мм | 0-180° | 20 об/мин | 800*650*900мм | 1-3мм | 3кВт 4-полюсный (национальный стандарт) | Трехфазный 380В | 230кг |

| Модель 51 | 20-51мм | 0-180° | 20 об/мин | 850*700*930мм | 1-4мм | 3кВт 4-полюсный (национальный стандарт) | Трехфазный 380В | 260кг |

| Модель 76 | 30-76мм | 0-180° | 16об/мин | 940*780*960мм | 1-5мм | 4кВт 6-полюсный (национальный стандарт) | Трехфазный 380В | 290кг |

| Модель 100 | 40-100мм | 0-180° | 16об/мин | 1020*800*960мм | 2-6мм | 5.5кВт 6-полюсный (национальный стандарт) | Трехфазный 380В | 360кг |

| Модель-5 Гидравлический ЧПУ | 4-28мм (стальной пруток), 10-50мм (круглая труба), 30*80мм (овальная труба) | – | – | 1100*1500*1200мм | – | 3 кВт (гидравлический мотор), 4 кВт (мотор передвижения) | – | 700 кг |

| Модель-9 Гидравлический ЧПУ | 4-32мм (стальной пруток), 10-60мм (круглая труба), 30*80мм (овальная труба) | – | – | 1100*1800*1200 мм | – | 3.8 кВт (мотор), 4 кВт (мотор передвижения) | – | 900 кг |

| Гидравлический ЧПУ модель-11 | 4-36мм (стальной пруток), 10-60мм (круглая труба), 30*80мм (овальная труба) | – | – | 1100*1800*1200 мм | – | 5.5 кВт (двигатель), 4 кВт (двигатель перемещения) | – | 1050 кг |

Гидравлическая арочная машина для изгиба канальных стальных балок H-образного сечения

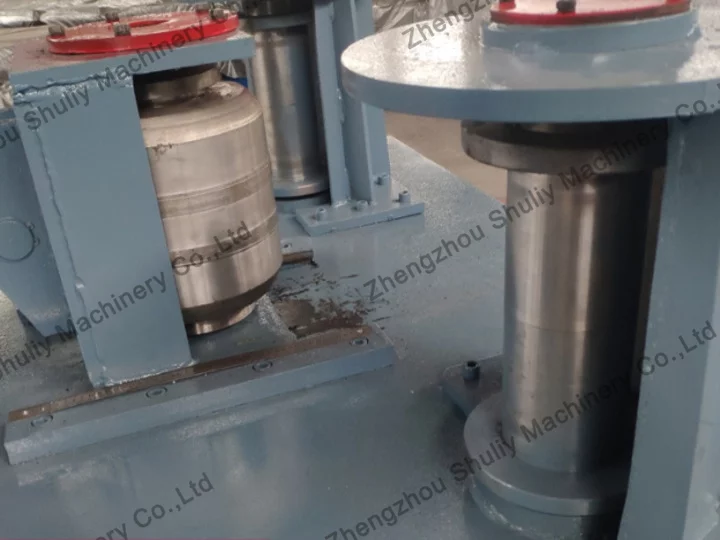

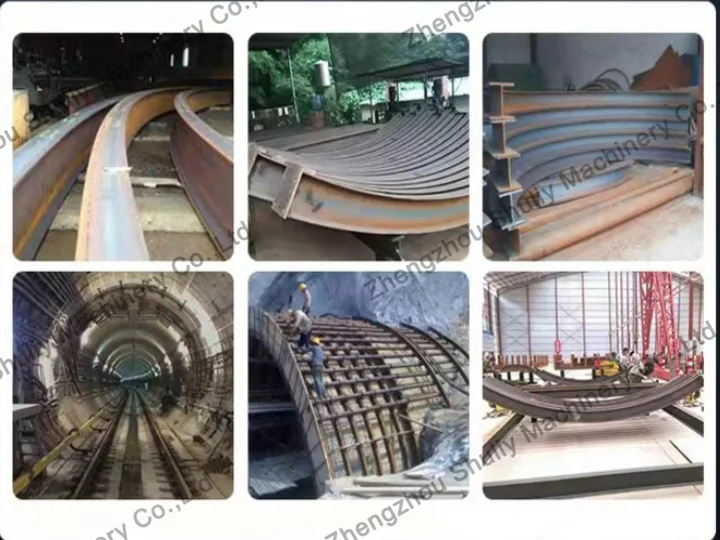

Гидравлическая машина для изгиба арок из стального канала H-балки, также известная как машина для холодного изгиба I-балок, является специализированным оборудованием, используемым для поддержки арок U-балок в туннелях. Она способна изгибать различные типы стальных профилей, включая H-балки, стальные каналы и I-балки.

Преимущества холодногибочного станка для двутавровых балок

- Широкий диапазон обработкиМашина может обрабатывать различные стальные профили. Например, она может работать с I-образными балками 25#, сталью 140H, 14-ми канальными стальными профилями, круглыми трубами 150 и квадратными трубами 150.

- Гидравлическая высокомощная передачаОн оснащен мощной гидравлической системой, которая обеспечивает эффективные и точные операции гибки. Давление гидравлической системы составляет 16 МПа.

- Настраиваемые формыМашина позволяет использовать индивидуальные формы для удовлетворения конкретных требований к изгибу, что делает её высоко адаптируемой к различным проектам.

- Общая мощность. Общая мощность машины составляет 3+3+3 кВт.

- Диапазон радиуса изгибаРадиус изгиба составляет 2 метра.

- Скорость главного колеса приводаСкорость главного ведущего колеса составляет 7,7 оборота в минуту.

- Эффективный и надежныйМашина разработана для обеспечения эффективной и надежной работы в сложных строительных условиях.

- Специализированное применениеЭто особенно полезно в проектах строительства туннелей, где требуется арочная поддержка в виде U-балки. Это помогает создавать стабильные структуры туннелей, обеспечивая необходимую поддержку и армирование.

Эта машина является незаменимым инструментом в строительных проектах, которые требуют изгиба крупных стальных секций, предлагая сочетание мощности, точности и универсальности.

Параметры гидравлического станка для изгиба

| Общая мощность | 3+3+3кВт |

| Диапазон радиуса изгиба | 2м |

| Давление в гидравлической системе | 16МПа |

| Скорость главного ведущего колеса | 7.7 об/мин |

| Вес машины | 1600 кг |

| Габаритные размеры | 250*150*80 см |

Не стесняйтесь обращаться к нам!

В заключение, наш ассортимент оборудования для обработки металлов, включая полностью автоматическую CNC машину для гибки стальных прутков с пятью головками, автоматическую CNC машину для гибки стальных прутков, CNC машину для гибки труб и гидравлическую машину для гибки арок из стального канала H-балки, предлагает эффективные, точные и надежные решения для различных промышленных применений. Каждая машина спроектирована для удовлетворения конкретных требований обработки, обеспечивая высококачественные результаты и повышенную производительность.

Наша линейка продуктов охватывает широкий спектр отраслей, от строительства и инфраструктуры до аэрокосмической и автомобильной промышленности. С передовыми технологиями и прочной конструкцией эти машины обеспечивают производительность и долговечность, необходимые для сложных задач обработки металлов.

В дополнение к этим представленным машинам, мы также предлагаем другое оборудование для обработки металлов, чтобы удовлетворить разнообразные производственные потребности. Наш широкий ассортимент продукции гарантирует, что вы сможете найти подходящие инструменты для оптимизации ваших операций и достижения превосходных результатов.

Для получения дополнительной информации или для ознакомления с нашим полным ассортиментом оборудования для обработки металлов, пожалуйста, не стесняйтесь обращаться к нам. Мы с нетерпением ждем возможности помочь вам найти лучшие решения для вашего бизнеса.