Matériaux appropriés pour la machine à cintre en fil – Choisissez les bonnes matières premières pour une production efficace

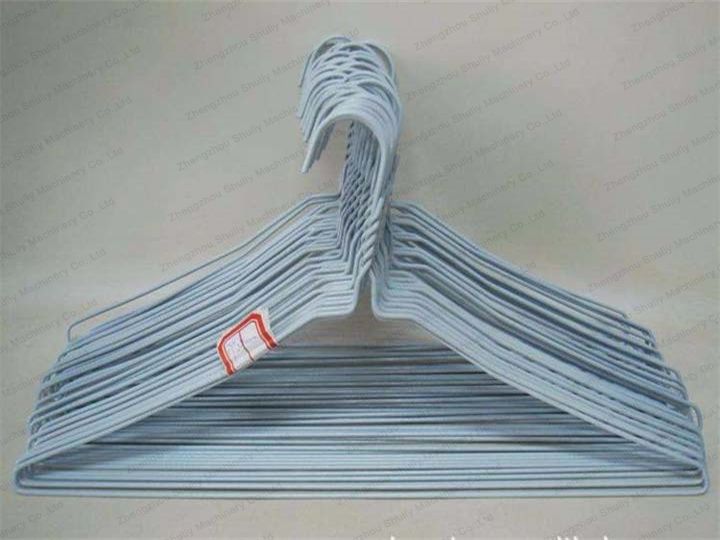

Une machine à cintre en fil est conçue pour la production de masse de cintres, traitant automatiquement le fil brut par des opérations d'alimentation, de pliage et de formation.

Le choix du bon matériau brut est crucial, car il influence la qualité du produit, la vitesse de production, l'apparence et le post-traitement comme le revêtement ou la pulvérisation.

Cet article explique les matériaux adaptés aux machines à cintre en fil et met en évidence les caractéristiques et applications de chaque matériau.

Metal Materials – High Strength and Durability

Machine à cintre en fil

- : Économique et facile à façonner, adapté à la production standard de cintres.Fil galvanisé

- : Recouvert de zinc pour améliorer la résistance à la rouille, idéal pour le stockage à long terme ou les environnements humides.Fil d'acier inoxydable (série 201/410)

- : Résistant à la corrosion avec une surface lisse, adapté aux cintres en fil haut de gamme.Fil d'aluminium

- : Léger et facile à former, parfait pour les designs de cintres légers.Ces fils métalliques peuvent être directement introduits dans une machine à cintre pour couper, plier et former, constituant la colonne vertébrale de la plupart des lignes de production de cintres.

Pour améliorer l'apparence, la sensation au toucher et les propriétés antidérapantes des cintres, de nombreux produits utilisent des fils métalliques recouverts de plastique ou de revêtement :

Coating and Plastic Materials – Improved Feel and Corrosion Resistance

: Ajoute des propriétés antidérapantes et résistantes à l'usure, disponible en plusieurs couleurs, idéal pour le marché de la vente au détail.

- Fil recouvert de plastique: Améliore la sensation au toucher et la résistance aux intempéries, adapté aux cintres extérieurs ou multifonctionnels.

- : Le revêtement est généralement effectué après la formation du cintre en utilisant des processus de pulvérisation ou d'enroulement, une étape courante dans les lignes de production modernes de machines à cintre en fil.Bien que le fil métallique soit la norme, certaines lignes expérimentent avec des matériaux légers ou décoratifs:

Matériaux plastiques (PP, ABS, etc.)

Other Innovative Materials – Lightweight or Design-Focused Hangers

Matériaux composites ou alliages spéciaux

- : Alliages légers ou plastiques renforcés peuvent être utilisés pour des designs de cintres haut de gamme ou personnalisés.Ces matériaux sont souvent utilisés dans la vente au détail professionnelle ou les produits domestiques haut de gamme et nécessitent un équipement de production compatible pour réaliser des designs diversifiés.

- Les matériaux adaptés aux machines à cintre en fil comprennent principalement des fils métalliques, des fils recouverts/plastifiés, et certains plastiques ou composites haut de gamme:Fil métallique

: Durable et efficace pour la production de masse.

Conclusion : Choisissez le bon matériau pour des performances optimales

Fil métallique recouvert de PVC / plastique

- : Allie esthétique et prise en main, idéal pour les cintres de vente au détail.Matériaux plastiques ou composites

- : Convient pour des designs légers ou haut de gamme.Lors du choix des matériaux, tenez compte de l'application, du positionnement du produit et des exigences de post-traitement pour garantir que la machine à cintre en fil atteigne la meilleure efficacité de production et la qualité du produit.

- Matériaux plastiques ou composites: Adapté aux designs légers ou haut de gamme.

Lors de la sélection des matériaux, prenez en compte l'application, le positionnement du produit et les exigences de post-traitement pour garantir que la machine à cintre en fil atteigne la meilleure efficacité de production et la qualité du produit.